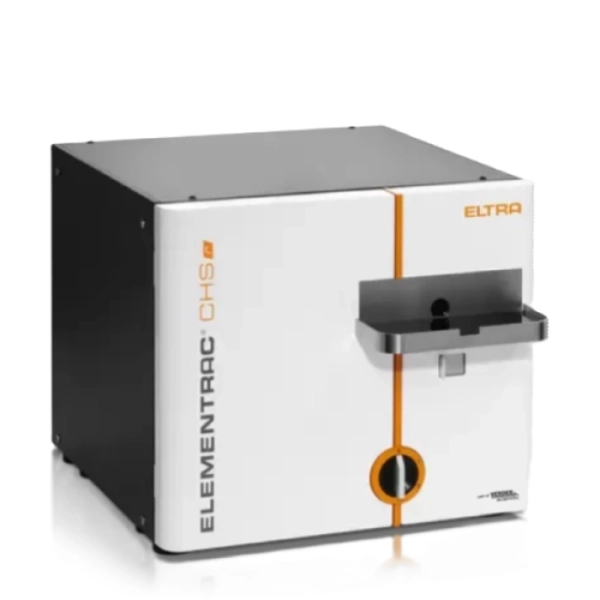

The CHS-r with up to 3 infrared cells is designed for carbon, sulfur and hydrogen measurement over a very wide concentration range. It uses a horizontal resistance furnace with ceramic tube, which operates in a range from 600 °C to 1550 °C.

The CHS-r combustion analyzer meets or exceeds the requirements of all common ASTM, DIN, EN or ISO standards for elemental analysis.

CARBON / SULFUR ANALYZER ELEMENTRAC CHS-r

- Fast, simultaneous measurement of carbon, sulfur and hydrogen

- High sample weight possible

- Optimized (low blank) sample port

- IR path made of solid gold for extended lifetime

- Wide measuring range from 20 ppm to 100%

OPERATION AND ANALYSIS PROCESS

The ELEMENTRAC CHS-r elemental analyzer determines the elements carbon, sulfur and hydrogen by combustion of the sample in an oxygen stream and subsequent measurement of the combustion gases CO2, SO2 and H2O in selective infrared measuring cells. A high sample weight of up to 500 mg ensures excellent reproducibility of the measurement results, even for heterogeneous samples.

The high combustion temperatures and electronic monitoring of the oxygen flow allow complete oxidation of the sample and help to avoid too low results even with challenging materials like cement. Regardless of the selected configuration (carbon - sulfur - carbon/sulfur - carbon/hydrogen/sulfur), operation is identical in all versions.

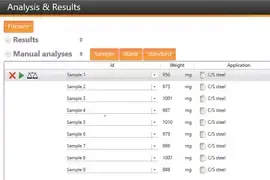

Step 1: Logging the sample into the ELEMENTS software

The sample ID is logged into the software and the weight is automatically transferred (see step 2). |

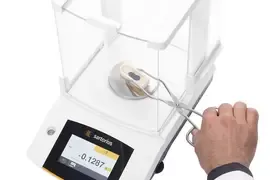

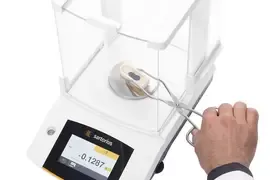

Step 2: Weighing and adding of accelerators

Volumes of 50 mg to 500 mg are typical for elemental analysis of carbon and sulfur. The sample is directly applied to a carrier (ceramic or Inconel boat) and analyzed without addition of accelerators. |

Step 3: Analysis

The sample is placed in front of the furnace opening and the measurement is started in the software. Subsequently, the shutter opens, and the material can be introduced into the hot furnace. At the same time, the ELEMENTS software continuously records measured values during combustion. Closing the furnace during the measurement is optional and can improve reproducibility. |

Step 4: Data output and export

60 to 240 seconds after the analysis has started, the measured carbon and sulfur concentrations are available for export as a report or via LIMS. Depending on the selected configuration, carbon and sulfur values are available for the individual sample. |

SOLUTIONS & OPTIONS IN DETAIL

The ELEMENTRAC CHS-r analyzer comes with various solutions for reliable, and precise carbon, hydrogen and sulfur analysis.

Included: Two Anhydrone Columns

For reliable carbon and sulfur analysis, the combustion gases must be freed from water vapor prior to IR detection. The CHS-r elemental analyzer is equipped with two drying columns filled with magnesium perchlorate to reliably prevent absorption effects in large sample volumes. In the case of TOC analysis, a chemical tube can also be used as a halogen trap to reliably absorb acid residues and halogens.

Included: Low blank sample port

The ELEMENTRAC CS-r and CHS-r analyzer series ensures safe and precise elemental analysis even of samples with low carbon content in the resistance furnace. Due to the optimized geometry of the sample port with reduced diameter, as well as an oxygen purge at the sample inlet, the CO2 blank value of the atmosphere during sample introduction is drastically reduced, thus enabling reliable carbon analysis in the low measuring range.

Option: Second Furnace (ELTRA Dual Furnace Concept)

The CHS-r elemental analyzer can be connected in any configuration to an additional furnace without detectors. This principle, known from the ELEMENTRAC CS-d, allows fast fractionated analysis by applying different temperatures and provides safety for high sample throughput.

Option: Monitor Holder

To make the most of available laboratory space, the ELEMENTRAC CHS-r analyzer offers various operating options:

- External monitor and keyboard

- Monitor holder, wireless keyboard

- Operation via touchscreen

Option: TIC Module

Depending on the sample, carbon can also be present in the two different fractions TOC (Total Organic Carbon) or TIC (Total Inorganic Carbon). The CHS-r elemental analyzer can be combined with ELTRA's TIC module to determine the TIC content via acidification. This combination enables reliable, direct TIC analysis in soils, building materials and other products in compliance with DIN EN 15936.

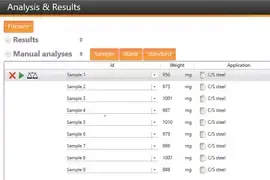

ELEMENTS SOFTWARE

The comprehensive Windows-based ELEMENTS software is an essential part of all ELEMENTRAC generation elemental analyzers.

A central window (analysis and results) is the starting point from which all functionalities required for the daily routine are easily accessible. From here it is possible to group and export analyzed samples, or register and analyze new ones. The user may call up various subordinate functionalities like application settings, calibration, diagnosis, or status.

TYPICAL SAMPLE MATERIALS

biomass, building materials, coal/ coke, fuels, oil, ores, plant materials, plastics, rubber, soil, soot, tobacco, waste, ...

TECHNICAL DATA

| Measured elements | carbon, hydrogen, sulfur |

| Samples | organic |

| Furnace alignment | horizontal (resistance furnace)

|

| Sample carrier | ceramic boats |

| Field of application | agriculture, biology, chemistry / plastics, coal / power plant, construction materials, environment / recycling, medicine / pharmaceuticals |

| Furnace | resistance furnace (ceramic tube), adjustable up to 1550 °C (steps of 1 °C) |

| Detection method | solid state infrared absorption |

| Number of IR cells | 1 - 3 |

| Material of IR path | gold |

| Typical analysis time | 60 - 180 s |

| Chemicals required | magnesium perchlorate, sodium hydroxide |

| Gas required | oxygen 99.5 % pure (2 - 4 bar / 30 - 60 psi) |

| Power requirements | 230 V, 50/60 Hz

max. heat up current 2000 W |

| Dimensions (W x H x D) | 58 x 52 x 75 cm |

| Weight | ~ 77 kg |

| Required equipment | PC, monitor, balance (resolution 0.0001g) |

| Optional accessories | TIC module |

FUNCTIONAL PRINCIPLE

In the elemental analyzer CHS-r the sample is burnt in an oxygen atmosphere at temperatures up to 1,550 °C. The furnace temperature can be freely selected in steps of 1 °C. The combustion gasses (CO2, H2O, SO2) coming from the furnace and first pass through a dust filter and then into the heated H2O infrared cell. After the water vapor is chemically absorbed, the dried CO2 and SO2 gas is detected in the additional infrared cells. Depending on the configuration, it is possible to combine up to three infrared cells with different sensitivities.