Cutting mills for laboratory and industrial applications

- Micro hardness testers

- Rocwell hardness tester

- Latest technology in universal hardness testing

- Customized hardness testing solutions

- Software

- Cut-off machines

- Floor-standing Cut-off Machines

- Clamping tools

- Consumables

- Hot mounting presses

- Pre-Grinder

- Manual grinder & polisher

- Automatic grinding & polishing

- Fully automated systems

- Electrolytic polisher and etcher

- Laboratory ovens to 700°C

- Industrial drying ovens up to 750 °C

- Clean room ovens

- Atmosphere Controlled Ovens

- Laboratory ovens up to 1800°C

- Industrial muffle furnaces up to 1800°C

- Muffle furnaces for combustion (ashing) up to 1200°C

- Annealing furnaces & ovens

- Universal tube furnaces up to 1800 °C

- Split tube furnaces up to 1800 °C

- Rotary tube furnaces

- Gradient Tube Furnaces

- Accessories and configurations for tube furnaces

- Vacuum Chamber Furnaces

- Vacuum hood furnaces

- Vacuum bottom loader furnaces

- Vacuum Laboratory Furnaces

- Vacuum Tube Furnaces

- Asphalt Binder Analyzer

- Tritium Furnaces

- Furnaces and ovens for testing coal and coke

- Custom designed furnaces & ovens

- Controllers

CUTTING MILL FEATURES

- Powerful size reduction – also of heterogeneous material mixes

- Selection of different cutting mill models to suit customer requirements

- Optimum cutting effects thanks to double acting cutting bars (SM 200 & SM 300)

- Cutting Mill SM 300 with variable speed from 700 to 3,000 min-1, 3 kW drive with high torque

- Rotational Energy Storage Technology (RES) provides exceptional cutting power reserves (SM 300)

- Defined final fineness due to bottom sieves with aperture sizes from 0.25–20 mm

- Low heat build-up

- Quick and easy cleaning thanks to push-fit rotors, smooth surfaces and foldback hoppers (SM 200 and SM 300)

- Highest safety standard due to motor brake, central locking device and electronic safety check

- Wide range of accessories including various hoppers, collecting systems, rotors and sieves

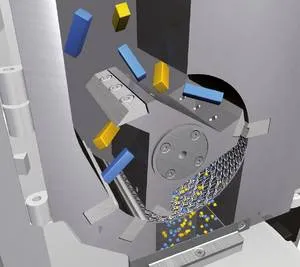

CUTTING MILL TECHNOLOGY

Size reduction in cutting mills is effected by cutting and shearing forces.

The sample passes through the hopper into the grinding chamber where it is seized by the rotor and is comminuted between the rotor blades and the stationary cutting bars inserted in the housing.

The dwelling time of the sample in the chamber is short; as soon as it is small enough to pass through the openings of the bottom sieve it is discharged and collected in the receptacle.