RETSCH Mixer mills - Efficient grinding and mixing of samples

- Micro hardness testers

- Rocwell hardness tester

- Latest technology in universal hardness testing

- Customized hardness testing solutions

- Software

- Cut-off machines

- Floor-standing Cut-off Machines

- Clamping tools

- Consumables

- Hot mounting presses

- Pre-Grinder

- Manual grinder & polisher

- Automatic grinding & polishing

- Fully automated systems

- Electrolytic polisher and etcher

- Laboratory ovens to 700°C

- Industrial drying ovens up to 750 °C

- Clean room ovens

- Atmosphere Controlled Ovens

- Laboratory ovens up to 1800°C

- Industrial muffle furnaces up to 1800°C

- Muffle furnaces for combustion (ashing) up to 1200°C

- Annealing furnaces & ovens

- Universal tube furnaces up to 1800 °C

- Split tube furnaces up to 1800 °C

- Rotary tube furnaces

- Gradient Tube Furnaces

- Accessories and configurations for tube furnaces

- Vacuum Chamber Furnaces

- Vacuum hood furnaces

- Vacuum bottom loader furnaces

- Vacuum Laboratory Furnaces

- Vacuum Tube Furnaces

- Asphalt Binder Analyzer

- Tritium Furnaces

- Furnaces and ovens for testing coal and coke

- Custom designed furnaces & ovens

- Controllers

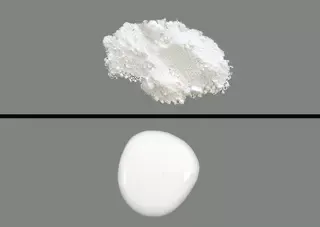

Mixer mills grind and homogenize small sample volumes quickly and efficiently by impact and friction. These ball mills are suitable for dry, wet and cryogenic grinding as well as for cell disruption for DNA/RNA or protein recovery. For special applications such as mechanosynthesis, they offer unique solutions. Mixer mills are well known for their ease of use and small foot-print compared to other types of ball mills.

MIXER MILLS - FUNCTION PRINCIPLE

MIXER MILLS - FIELDS OF APPLICATION

Mixer mills are used for the pulverization of soft, hard, brittle, and fibrous materials in dry and wet mode. With their small footprint, ease of use, and very short processing times, they are true allrounders in the laboratory.

Mixer mills are ideally suited for tasks in research like mechanochemistry (mechanosynthesis, mechanical alloying and mechanocatalysis), or ultrafine colloidal grinding on a nanometer scale, as well as for routine tasks such as mixing and homogenizing.

They are also widely used for cell disruption for DNA/RNA extraction via bead beating. Up to 240 ml of cell dispersions can be processed for protein extraction or metabolome analysis.

A crucial advantage of mixer mills is their great versatility – in some models combined with the capacity to actively cool or heat material, allowing for more controlled configurations than in other ball mills. In the field of mechanochemistry, the possibility to control the reactions inside the jar is very beneficial.

Depending on the models, temperatures down to -196°C or up to 100°C can be applied. Mixer mills are available with 1, 2 or 6 stations. Jars and balls are available in various sizes, designs and materials.

titanium oxide

| metal alloy

| hair

| tyre rubber

|