Continuous heat treatment: carbon fibres

DEBINDING UP TO 800°C

PRE-SINTERING UP TO 1300°C

HIGH TEMPERATURE SINTERING UP TO 2200°C

SIMULTANEOUS HEAT TREATMENT OF MULTIPLE CARBON FIBRES

CARBOLITE GERO CUSTOM FURNACES & OVENS EXAMPLES

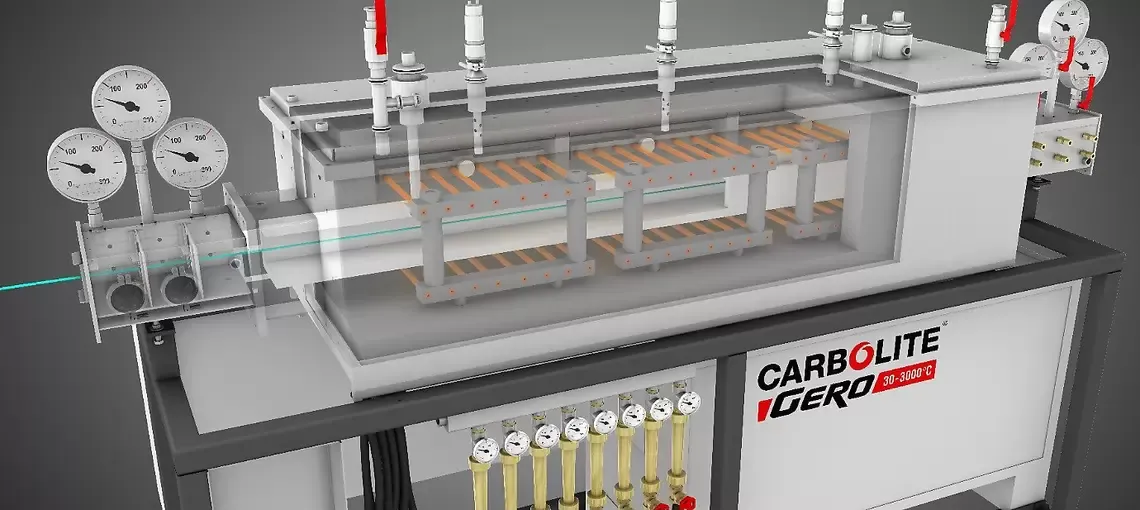

Interior view of custom designed tube furnace up to 2200 °C, with integral compact frame including gas and water supply, separate temperature controller cabinet and flanges for inert gas counter flow, for open operation during inert gas heat treatment of four carbon fibres under inert gas atmosphere. Supplied with separate control cabinet.

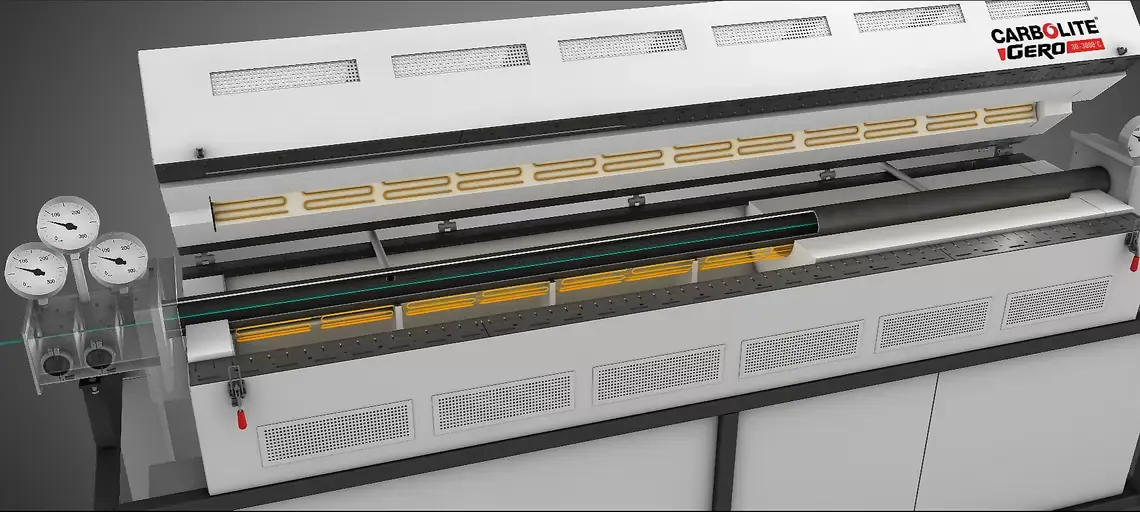

Interior view of custom designed 6-zone FZS 13/100/3000 up to 1300°C with 3000 mm heated length and counter flow flanges for inert gas counter flow for open operation during inert gas heat treatment of four carbon fibres under inert gas atmosphere. Supplied with separate control cabinet.

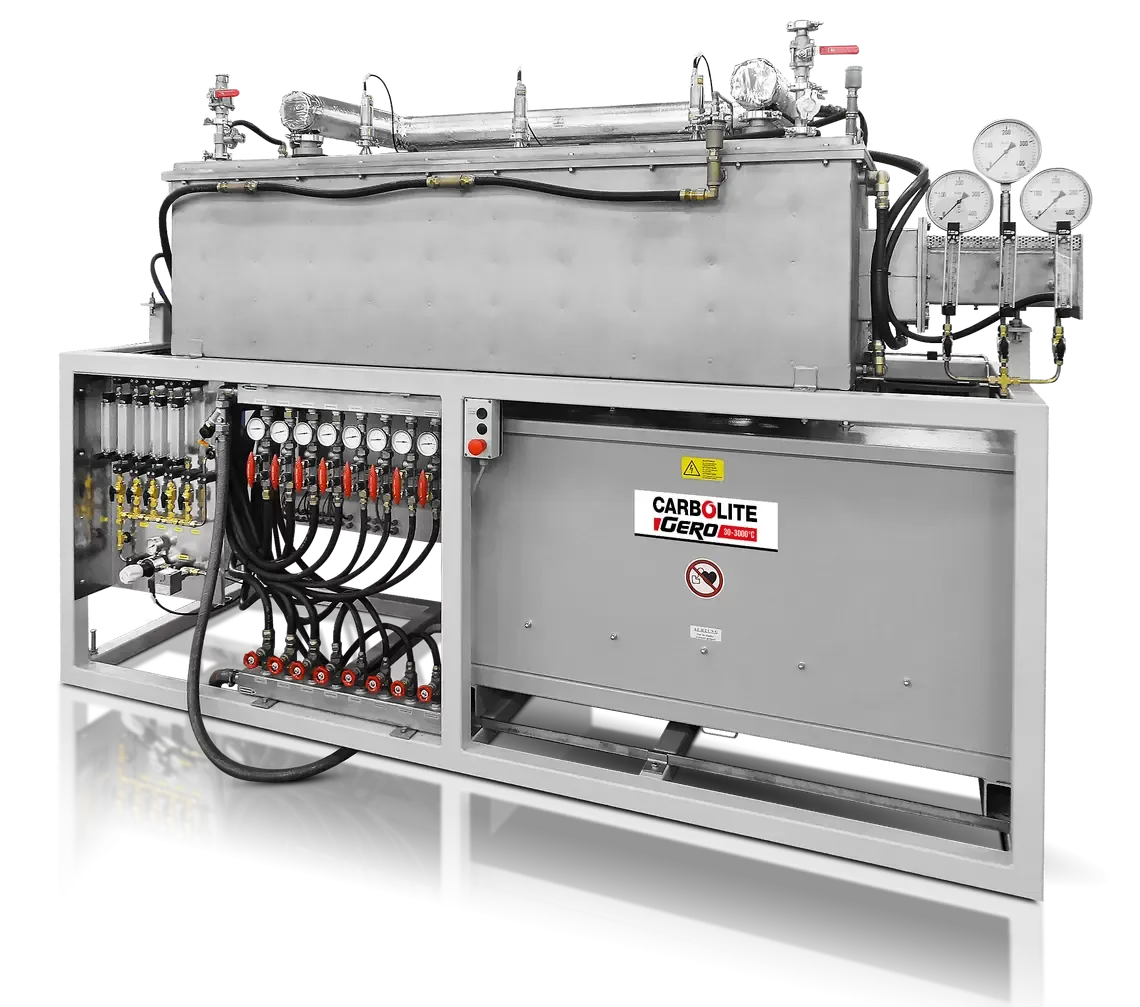

Custom designed manually controlled horizontal graphite heating and insulated tube furnace up to 2200 °C, with integral compact frame including gas and water supply, separate temperature controller cabinet and flanges for inert gas counter flow for open operation during inert gas heat treatment of four carbon fibres under inert gas atmosphere. Supplied with separate control cabinet.

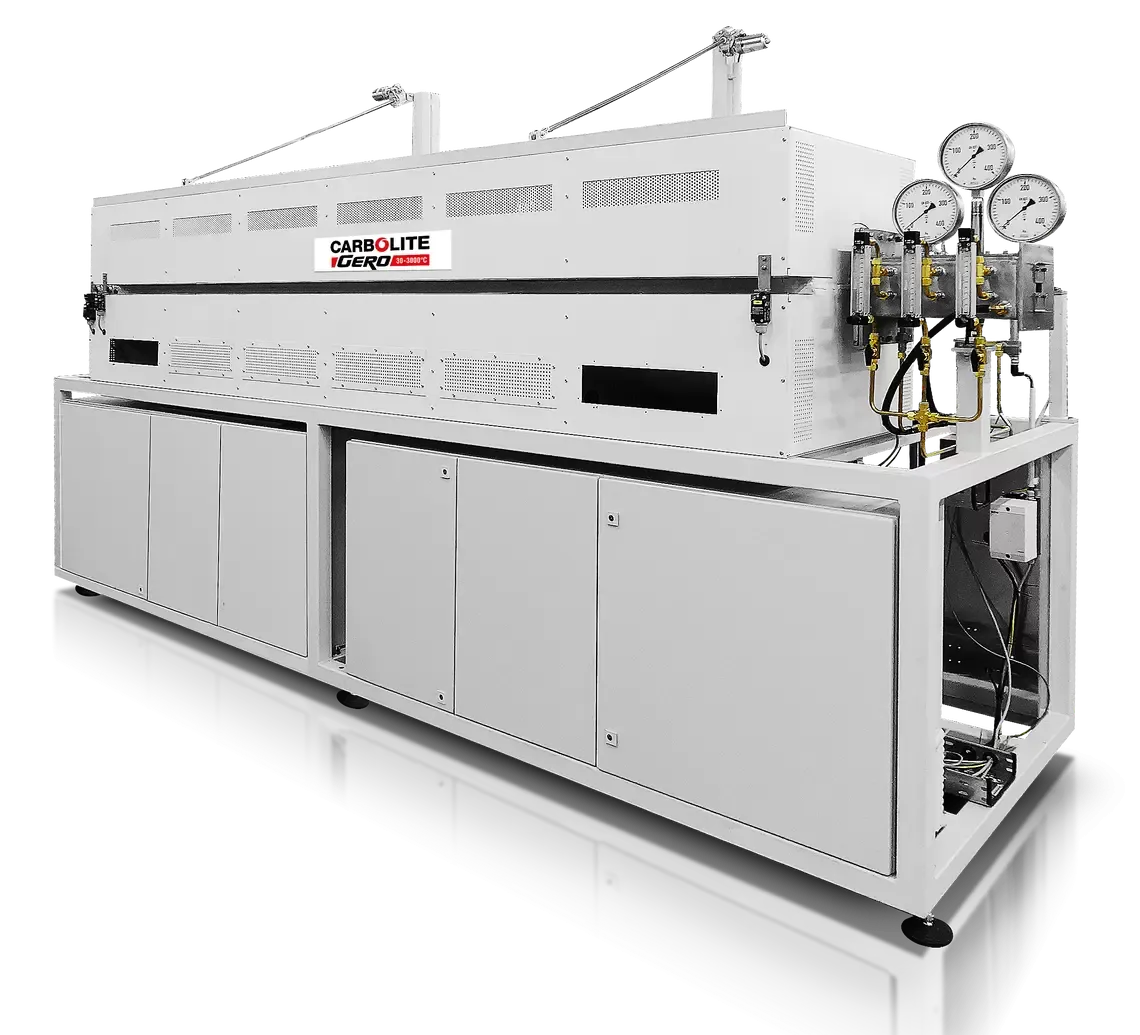

Custom designed 6-zone FZS 13/100/3000 up to 1300°C with 3000 mm heated length and counter flow flanges for inert gas counter flow, for open operation during inert gas heat treatment of four carbon fibres under inert gas atmosphere. Supplied with separate control cabinet.

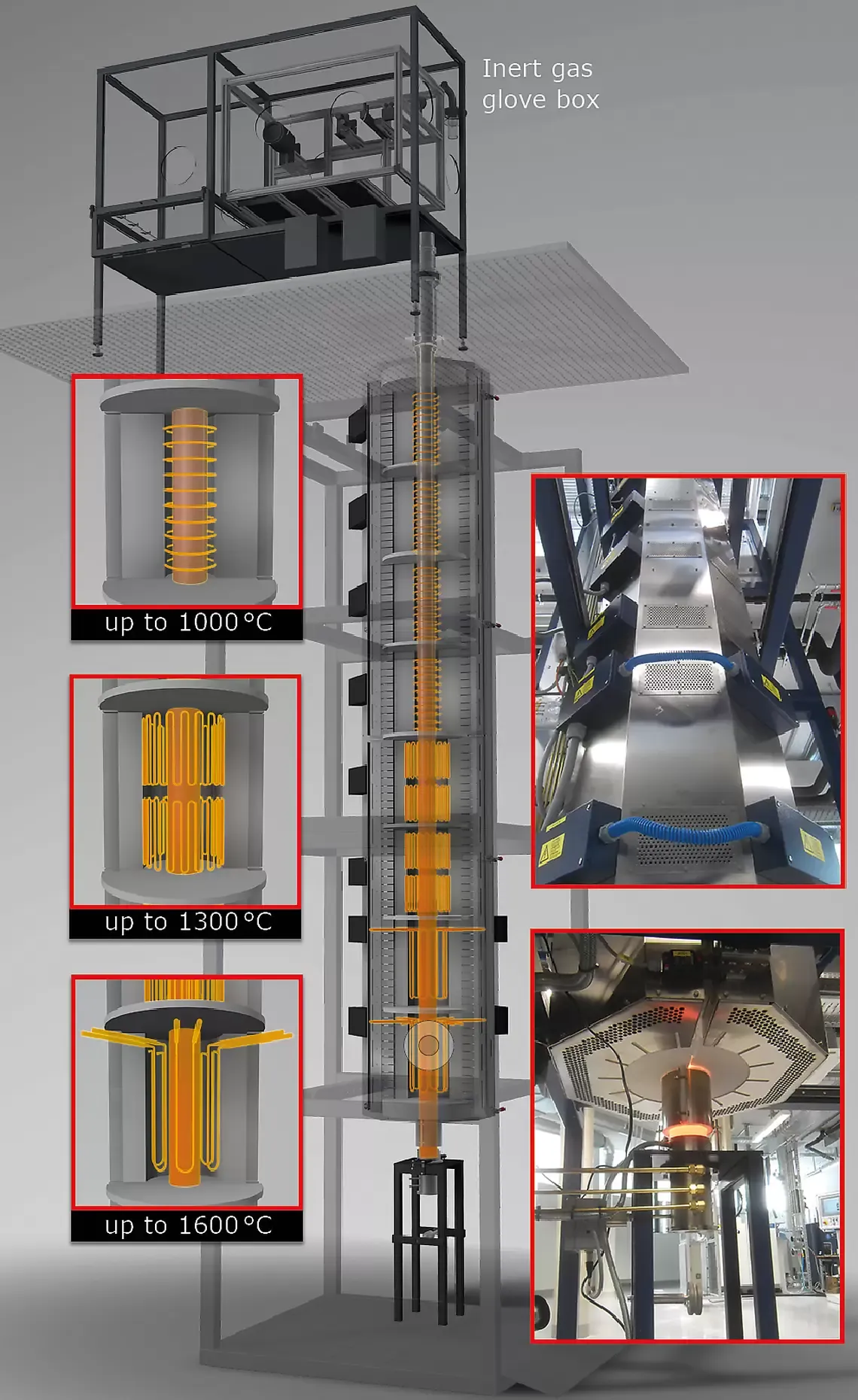

Custom designed 8-zone vertical split tube furnace model HTRV-A 16/100/4000 up to 1600°C with 4000 mm heated length. For debinding and sintering of fibres under inert gas atmosphere. The fibres are introduced into the furnace from an inert gas glove box.