Hydro LV large volume dispersion unit

Overview

- 600 ml dispersant volume

- 40 W in-line sonication probe, for rapid agglomerate dispersion

- Powerful centrifugal pump system ensures bias-free sampling

- Automated dispersant supply

- Full software control of all measurement functions, including dispersant supply, sample dispersion and cleaning

- Chemically compatible with a wide choice of organic and inorganic dispersants

- Integral sample tank light

How it works

Dispersing a sample within a liquid involves wetting and separating each individual particle. The aim is to produce a stable, completely dispersed suspension for measurement.

In order to promote wetting, it is vital to select an appropriate dispersant. Water is the one most commonly used and, when suitable, offers many benefits in terms of cost of measurement and sample disposal. However, non-aqueous dispersants may need to be used in some applications, such as those involving water soluble particles.

The application of sonication promotes the wetting process, by disrupting the structure of any agglomerates. Stabilizers may also be added to the dispersant to prevent re-agglomeration.

Certain wet dispersion applications require relatively large sample volumes. With polydisperse materials, for example, it is necessary to take enough sample to ensure a measurable particle population at either extreme of the distribution. Large samples translate directly into a large dispersion volumes because measurement concentration must be relatively dilute for effective laser diffraction analysis.

The Hydro LV is designed for large volume wet dispersion. In-line sonication promotes the dispersion process while a powerful centrifugal pump prevents sedimentation, ensuring that all the sample is measured, in a bias-free way. This is especially important when attempting to detect the presence of a small number of large particles that have a tendency to sediment out of suspension. Automated dispersant delivery accelerates analysis.

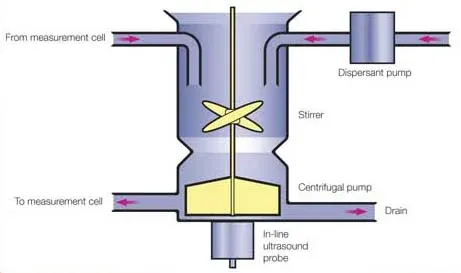

Wet Dispersion unit schematic, showing the sample tank, stirrer, centrifugal pump and in-line sonication system.

Wet Dispersion unit schematic, showing the sample tank, stirrer, centrifugal pump and in-line sonication system.