Spectrometer for metals and alloys ARTUS 10

Артикул: ARTUS 10

First direct reading spectrometer using CMOS and refrigeration technology.

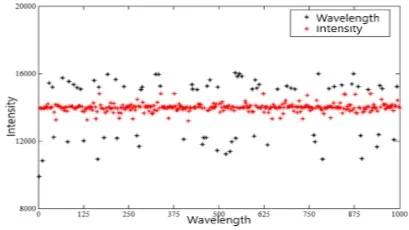

The newly designed ARTUS 10 includes a new scientific-grade CMOS sensor which enables a shorter analysis time of some metals to be as short as 10 seconds. Added intelligent algorithms eliminate background interference for enabling optimal analysis performance.

Newly added features on the ARTUS also include a dual optical system; gas channel fluid design; die-cast aluminium encased light chamber; A-Care cloud service system; tool-free access to the UV and visible optic lenses; and a “clasping type” electrode locking device.

The ARTUS 10 is the first direct reading spectrometer using CMOS and thermoelectric cooling technology. It is the ideal spectrometer for industries that process incoming steel, non-ferrous, unknown and composite metals material for in-process testing and final quality control. It meets the needs of users looking for a high-end solution.

Key Features

- Very useful for customers with mass detection requirements for steel, casting, non-ferrous, unknown and composite metals material.

- The test time is short and the single analysis time of some metals can be as short as 10 seconds.

- Powerful Aberrant Spark Removed (ASR) technology removes aberrant sparks and reduces sample preparation requirements.

- The argon-filled dual optical cell design ensures high analysis performance of long and short-wave elements and avoids pollution and drift caused by the vacuum system.

- Excellent combination of hardware and algorithms; no drift correction; more stable.

- Detection efficiency is improved and argon gas is saved by more than 2/3.

- Newly added “clasping type” electrode fixture makes it simple for maintenance.

- One-click excitation; easy to use.

- Spectrometer, internet and A-care service enables recognition of the cloud interconnection, instant automatic notification of device anomalies, remote software upgrade, maintenance and feedback.

- Functional module graphical design and software operation is simple and more user friendly.

- Graphical display of the status of each module of the instrument helps to clearly judge the operation of the equipment.

- Switching the sample control type does not require reloading the model.

- Single interface for daily operations.

Models

| MODELS OF

ARTUS 10 | INSTRUMENT

PART NO. | ANALYTICS CALIBRATION | FIELDS OF APPLICATION |

| Ultimate Plus

ARTUS10-ULT-PLUS | AA1040019UP | All optical system refrigeration can be analysed: Fe, Al, Cu, Ni, Zn, Mg, Co, Ti, Sn, Pb plus other 10 kinds of matrix, more than 40 kinds of elements. |

|

| Ultimate

ARTUS10-ULT | AA1030019U | Can analyse Fe, Al, Cu, Ni, Zn, Mg, Co, Ti, Sn, Pb and other 10 kinds of matrix more than 40 kinds of elements. |

|

| Standard

ARTUS10-STD | AA10100195S | Can analyse Fe, Al, Cu, Ni, Zn, Mg, Co, Ti, Sn, Pb and other 10 kinds of matrix, more than 40 kinds of elements. |

|

| Basic

ARTUS10-BASIC | AA1050019B | Can analyse Al, Cu, Zn, Mg, Sn, Pb and other non-ferrous metal materials. |

|