X-ray energy dispersive spectrometer (EDXRF) Epsilon Xline

High-Precision Material Analysis

The Epsilon Xline spectrometer is a modern instrument designed for accurate analysis of various materials. Utilizing advanced technologies, it delivers high-precision measurements and consistent performance in both laboratory and industrial applications.

Main Advantages of Epsilon Xline

- High measurement precision

- Advanced analytical technologies

- User-friendly operation and maintenance

- Wide range of applications

In-line control for continuous roll-to-roll processes

- Non-destructive in-line process control – no sampling required

- Range of scanning modes to accommodate patch continuously, and multi-lane coating processes

- Easy to integrate into production processes with standard communication protocols

- Able to measure all valuable elements of interest, including platinum and cerium

- Capable of measuring thin layers with excellent precision

- Accommodates a range of roll widths

- Unique patented robotic arm that provides optimal distance control by hovering the measurement head over the production line in all directions

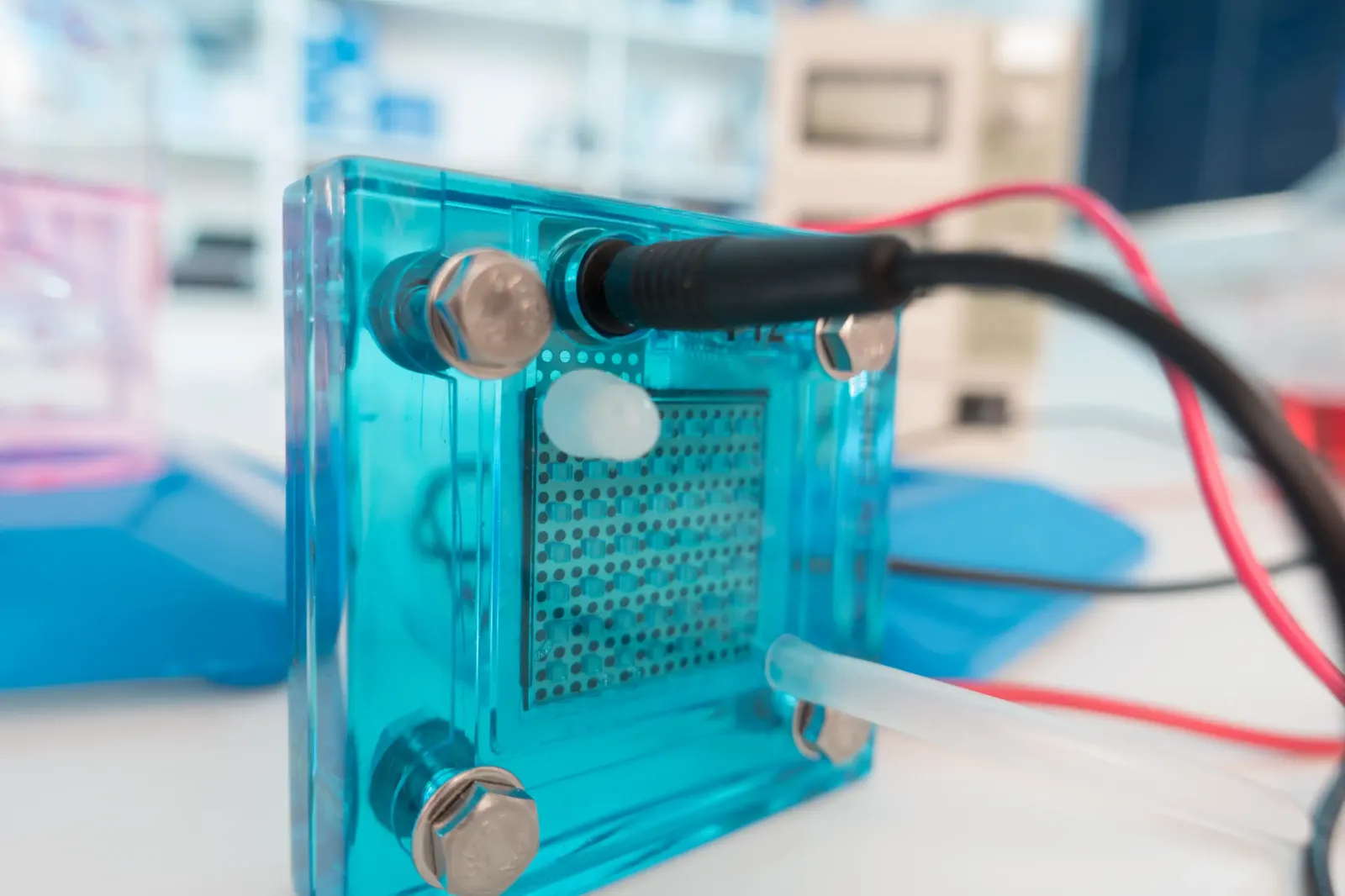

Facing the challenges of fuel cell production

With platinum catalysts accounting for more than 20% of your overall fuel cell costs, optimizing catalyst coating through uniform dispersion and consistent layering is essential. And fast, accurate process monitoring is the ideal solution! The Epsilon Xline makes efficient operational control easy, helping you to:

- Minimize your off-specification production

- Save valuable platinum from being wasted

- Produce cost-competitive end-products

Features

Full in-line automation. Enjoy continuous R2R production thanks to the Epsilon Xline’s seamless integration capabilities, suitable for a range of thin-film and coating applications.

Simple and safe. The Epsilon Xline is fully X-ray safe and easy to use, unlike handheld or legacy instruments, and delivers highly accurate analytical data.

A lifetime of experience. Drawing on Malvern Panalytical’s more than 70 years’ experience in elemental analysis , the Epsilon Xline was developed in collaboration with our industry partners to meet their needs of today – and at the same time looking to the industry’s future together.

Maximized yield. Achieve cost-competitive production with real-time monitoring and no disruption – giving you the direct insights and control you need to get the most out of your operations.

Optimum materials efficiency. Eliminate inconsistencies, avoid wasting precious materials, and ensure a high-quality product with our industry-standard solution.

Proven, patented accuracyє. Developed and tested with customers, the Epsilon Xline features patented height-correction technology that ensures stable analysis for accurate results.

Proven technology

Elemental analysis within your process

X-ray fluorescence (XRF) is a non-destructive elemental analysis technology that enables in-line monitoring during the coating processes of catalytic membranes – without the need to take samples and without chemical or physical changes.

The resulting real-time in-line analysis enables the rapid optimization of many process parameters and product properties.

Highly repeatable and accurate measurements with low maintenance

The proven and robust technology used in the Epsilon Xline and throughout our series of Epsilon instruments is powered by the latest advances in excitation and detection technology. A well-designed optical path, a wide range of excitation capabilities for light and heavier elements, and a fast high-resolution SDD detector system contribute to the power of the Epsilon Xline. These innovations result in highly repeatable and accurate results with low maintenance.

Specification

| Sample handling | |

| Sample type | Coating line |

| Coating types | Continuous, lanes, patches |

| Line speed continues coating | Maximum 30 m/min |

| Line speed patch coating | Maximum 11 m/min |

| X-ray tube | |

| Type | Metal-ceramic, side-window |

| Anode material | Ag |

| Tube Setting | Software controlled, applicable voltages 4 - 50 kV, max. 3 mA, max. tube power 15 W |

| Tube filters | Six, software selectable (Cu 300 µm; Cu 500 µm; Al 50 µm; Al 200 µm; Ti 7 µm; Ag 100 µm |

| Window thickness | 50 µm (Be) |

| Detector | |

| Type | High-resolution Si drift detector SDD10 |

| Window | 8 µm (Be) |

| Resolution | < 145 eV @ 5.9 keV/1000 cps

Typically 135 eV @ 5.9 keV/1000 cps |

| Safety Standards | |

| Radiation | < 1 µSv/h at 10 cm of the outside surface |

Built-in connectivity