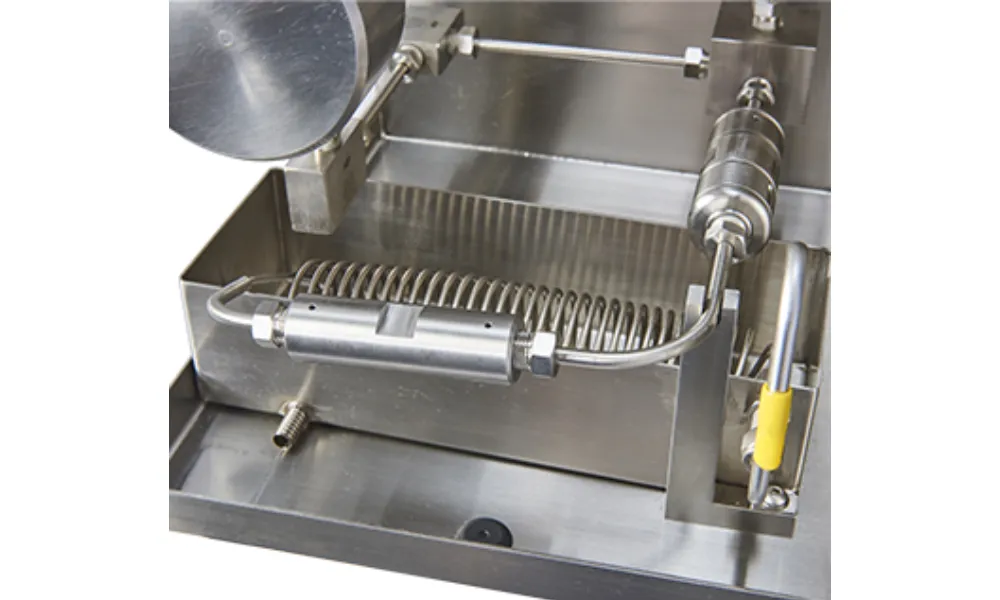

M110P Microfluidizer Processor

Артикул: М110 Р

A 'Plug & Play' High Shear Benchtop Processor

The Microfluidizer M110P processor is a premium lab-scale model that is ready to set to work. It's a simple-to-use, electric benchtop fluid homogenizer.

Using the Microfluidics fixed-geometry Interaction Chamber™ technology and a ceramic (Zirconia) plunger, the M110P is capable of successfully processing a wide variety of fluids, including oil-in-water emulsions, solids-in-liquid suspensions and performing cell disruption of yeasts and plant cells — much of which is performed with as few as one or two passes.

The M110P is powered by a standard 20-amp single-phase electrical outlet. The onboard 1.5 kW (2 HP) electric-hydraulic drive powers a single-acting intensifier pump. Process pressures are adjustable up to 2068 bar (30,000 psi) to produce the desired product results. No need for compressed air or hydraulic cooling water.

This versatile laboratory homogenizer conveniently fits under most standard laboratory chemical hoods.

The lab scale M110P delivers a repeatable process with results that are guaranteed to scale up to pilot and production volumes.

Standard Features

- 300 ml Glass Feed Reservoir

- Diamond Interaction Chamber

- Ceramic (Zirconia) plunger

- Stainless steel enclosure

- Electric/hydraulic drive method

- Mechanical product pressure gauge

Optional Features

- Larger capacity glass or stainless-steel reservoirs

- Temperature sensors displayed on HMI

- Sanitary flush diaphragm pressure transducer displayed on HMI

- Batch processing

- Seal quench system

Biopharma Features

- Includes all features required to achieve cGMP as specified by the American Society for Mechanical Engineers Bioprocessing Equipment (ASME BPE)

- Traceability – Material Certificates for all product contact parts included in an electronic Turnover Package (TOP)

- Surface Finish – Electropolished and passivated to achieve surface finish of < 20 Ra where possible.

- USP Class VI elastomers

- Drainability – A sanitary heat exchanger, a sanitary flush pressure transducer and pitched piping are included to ensure all equipment can be drained effectively.

Optional Biopharma Features

- Larger stainless steel reservoirs

- Batch processing

- Seal quench system

- Preventative maintenance service

- IQ/OQ documentation and execution