Morphologi 4 particle analyzer

Артикул: Morphologi 4

Rapid, automated particle size and particle shape analysis

Morphologi 4 provides detailed morphological descriptions of particulate samples through static image analysis, enabling a greater understanding of both sample and process. It can equally be used as an R&D tool to investigate challenging applications and in automated QC analysis where generation of robust, user-independent results and validation are required.

Features and benefits

The Morphologi 4 measures the particle size and shape of dry powders, wet suspensions and particulates on filters. Designed to accommodate the diverse needs of a multidisciplinary R&D lab, it is the ideal replacement for costly and time-consuming manual microscopy.

- Broad particle size range, from 0.5 μm to over >1300 μm, enables size measurements of a wide range of samples

- 20+ morphological parameters deliver a highly-detailed description for deeper understanding of your particulate material

- SOP control, from sample dispersion to data analysis, provides simple and automated operation for robust, repeatable measurements

- Automated ‘Sharp Edge’ analysis enables detection of even low contrast particles

- Advanced manual microscope mode and ability to return to particles of interest enables an even closer examination of unexpected particles

- High resolution microscope ensures quality particle images for optimum image analysis data

- Integrated dry powder dispersion unit delivers reproducible sample dispersion, critical to achieving meaningful results

- Dedicated sample presentation accessories enable measurement of a wide variety of sample types, including suspensions and filters

- Advanced data exploration tools generate maximum sample knowledge

- 21 CFR Part 11 software option ensures regulatory compliance

- Conforms to standards: ISO 9276-6 and ISO 13322-1

How it works

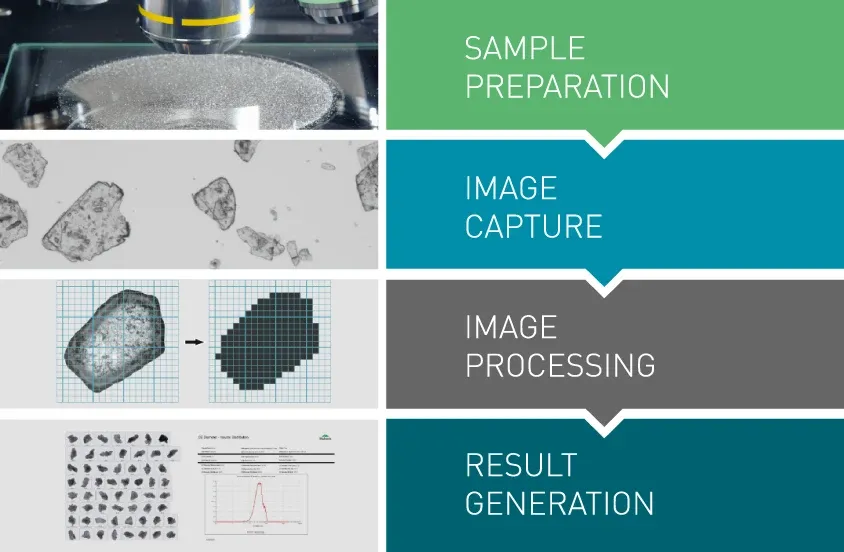

The Morphologi 4 measurement procedure can be split into four sections:

Sample preparation

Spatial separation of individual particles and agglomerates is critical to representative results. The integrated dry powder disperser makes preparing dry powder samples easy and reproducible. The applied dispersion energy can be precisely controlled, enabling the measurement process to be optimized for a range of material types. Dispersion is achieved without explosively shocking the particles, avoiding the damage of fragile particles whilst ensuring strongly-agglomerated materials are dispersed. Accessories that fit directly in to the Morphologi 4’s automated stage are available for preparing suspended or filtered samples.

Image capture

The instrument captures images of individual particles by scanning the sample underneath the microscope optics. The Morphologi 4 can illuminate the sample from below or above, whilst accurately controlling the light levels.

Image processing

Use of either the automated ‘Sharp Edge’ segmentation analysis or the manually-controlled thresholding enables the detection of particles and the calculation of a range of morphological properties for each.

Results generation

Statistically representative distributions are constructed for each parameter from the thousands of particles that have been analyzed. Advanced graphing and data classification options in the software ensure that extracting the relevant data from the measurement is straightforward, via an intuitive visual interface. Individually-stored grayscale images for each particle provide qualitative verification of the quantitative results.