The Discover® 2.0 is the premier microwave reactor for performing any organic or inorganic synthetic chemistry. Featuring a best-in-class 300 mL single-mode microwave cavity and intuitive software with a 10" touchscreen interface, it is possible to program a reaction in seconds and achieve the best synthetic yield in minutes.

Features

- Widest pressurized vessel sizes for a single-mode microwave - 10mL, 35mL, 100mL

- IR Temperature Sensor that sees through glass and Teflon® (iWave®)

- Vent and reseal technology for safe handling of over-pressurization (ActiVent)

- Variable speed magnetic stirring and rapid compressed air cooling

- Upgrade options: Autosamplers - 12/48 positions; Gaseous Addition, Flow cells

Microwave Advantage

The Absolute Best Approach for Chemical Synthesis

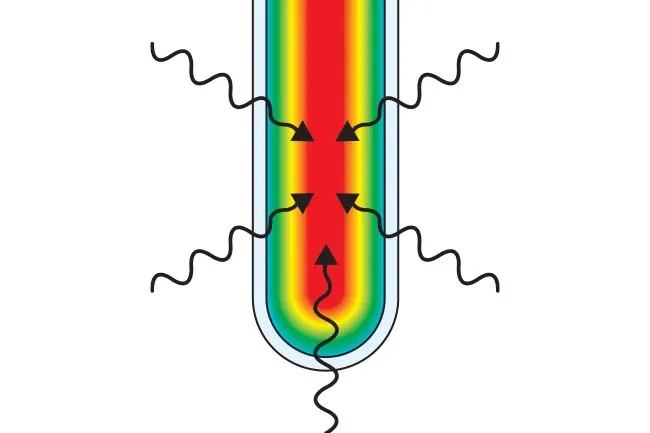

Microwave synthesis provides unique heating benefits for synthetic chemistry.1-3 Reactions are heated volumetrically, directly, and instantaneously, faster and more efficiently than any other form of heating. These microwave characteristics give organic chemists better product yield and more control over reaction conditions for precise results in materials and inorganic chemistry. Microwave energy is the industry standard for medicinal chemistry, nanomaterials synthesis, and academic teaching labs, owing to these clear advantages.

| Conventional Heating | Microwave Heating |

- Dudley, G. B.; Richert, R.; Stiegman, A. E. Chem. Sci. 2015, 6, 2144-2152.

- Chen, P.-K.; Rosana, M. R.; Dudley, G. B.; Stiegman, A. E. J. Org. Chem. 2014, 79, 7425-7436.

- Hunt, J.; Ferrari, A.; Lita, A.; Crosswhite, M.; Ashley, B.; Stiegman, A. E. J. Phys. Chem. C 2013, 51, 26871-26880

Accuracy

iWave - IR That Sees Through Glass and Teflon

For the first time, a single-mode microwave synthesizer reactor utilizing iWave, an intelligent IR sensor that can see through glass and Teflon and measures the temperature of your sample NOT the vessel! Based on new technology this powerful update eliminates the need for costly and fragile internal fiber-optic probes while providing the most accurate and responsive temperature measurement available.

Safety

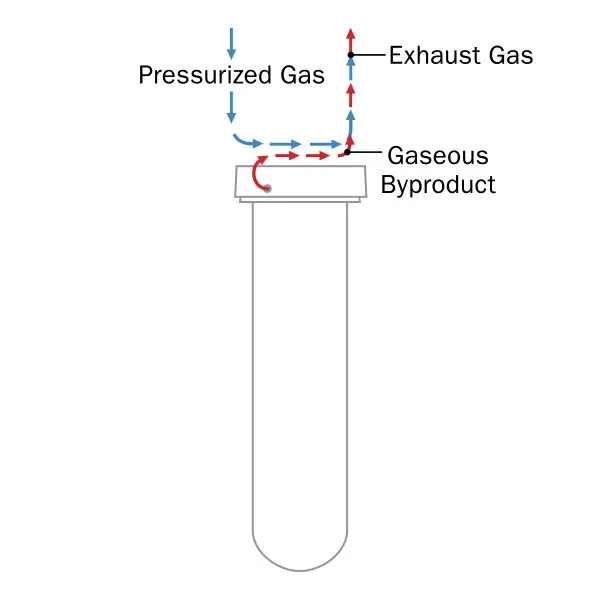

Activent — Safe, Pressurized Reactions

The Discover 2.0 patented pressure management technology is the latest advance in automated pressure control and the safest way to perform pressurized reactions. This system automatically relieves gaseous byproducts as they form during the reaction, venting safely through exhaust tubing at the back of the system. This significantly reduces vial failures and allows your reactions to reach higher temperatures while requiring only an easy-to-use snap on cap without the need for crimping tools.

Vessels

Use The Widest Range of Sealed Vessels Available

Discover 2.0 offers the widest range of high-temperature, high-pressure sealed reaction vessels, standard. Perform pressurized reactions in either 10, 35, or 100 mL vials. Alternatively, run non-pressurized, open vessel reactions in standard laboratory glassware up to a 125 mL round-bottom flask. If your chemistry etches glass (HF or strong inorganic bases), use a silicon carbide vessel or even disposable Teflon®liners to get the best results.

Integrated Camera

Observe Your Reaction

The optional 5 megapixel camera can be used to record still images or video footage of reactions. Observation is a basic part of science, and this is the perfect tool for documentation and publication support.

Software

Intuitive Software For Any Chemist

Fully customizable methods and cycles for any synthetic chemistry. User level access with full password protection and complete audit trail traceability. Method import reduces programming errors and allows easy access to niche chemistries.