Micro hardness tester QNESS 60 A+ EVO

The Brinell / Knoop / Vickers hardness tester series Qness 60 EVO takes micro hardness testing to a whole new level: The high-end laboratory devices of the latest generation combine the best of both worlds – hardness testing and microscopy without compromise and with maximum operating convenience. The revolutionary optical system with color camera provides reproducible and reliable results every time.

- Wide test force range (0.25 g – 62.5 kg)

- ASTM+DAkkS certified Vickers diamond included

- Dynamic test turret with 8-position tool changer

- White LED light with motorized aperture shuttering

- Qpix Control2 Software with intuitive 3D control elements

- Modular activation of INSPECT microscopy features

- Fully automated, unmanned test and analysis cycles

- XYZ axis control with direct optical path measuring system (resolution of 0,5 µm)

- Variant A+ only: Sample image camera with automatic image acquisition (49 x 37 mm)

HARDNESS TESTING

UNLIMITED OPTIONS

| VERTICAL CONCEPT WITH 2 Z-AXES

There are decisive benefits in distributing vertical movement across 2 axes. Via the first Z-axis there is dynamic motion control, allowing the indenter to be positioned towards the test surface quickly and conveniently at up to 30mm/s. The additional second Z-axis in the QATM system offers a high-resolution positioning system for greater precision in force application and focusing. | AUTOMATED HARDNESS TESTING AND MICROSCOPY

It is now possible to execute all required quality assurance tasks with a previously unattained degree of convenience and time efficiency. The Brinell / Knoop / Vickers hardness tester 60 A+ EVO can work through hundreds – even thousands – of test and analytical points in a fully automated, unmanned setting. The analytical functions have also been integrated in order to enable the operator working in a manual mode to analyze material properties with maximum efficiency, and to deliver the requested results smoothly and simply. |

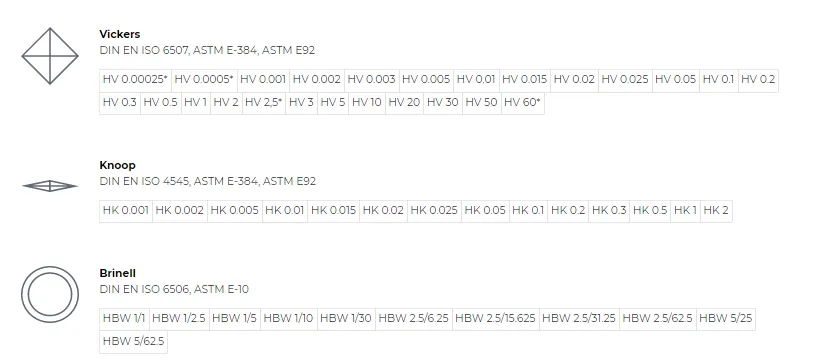

TEST METHODS & FORCE RANGE

HARDNESS TESTER OR MICROSCOPE? BOTH.

| REVOLUTIONARY OPTIC SYSTEM

The QATM-developed, in-house manufactured lens system sets new standards. In addition to providing crystal clear image quality for micro hardness testing, Koehler illumination uses white LED light and motor-operated aperture shuttering to produce ideal contrast, even for high magnification images. The color-corrected high-quality lens series is used for structural analysis. There are also two camera systems to choose from. Experienced metallurgists agree the image quality provided by the Vickers / Knoop / Brinell hardness tester Qness 60 EVO is comparable in all aspects with that of established sophisticated microscopes. The up-to-date concept and new lenses in the optic system enable the device to completely meet even the strictest physical ‘test system definition’ requirements in compliance with DIN EN ISO6507-1/2:2018. | 8-POSITION TOOL CHANGER

Up to 8 different test diamonds or lenses can be mounted to the ultra-modern turret of the Vickers / Knoop / Brinell hardness tester. The compact structure is angled at 20° to guarantee excellent test room visibility. Highlight: The newly developed hardness testing modules serve as modular indenter holders enabling plug-and-play retrofitting of Brinell and Knoop test equipment at any time after delivery. | INTERACTIVE SOFTWARE FOR ALL VERSIONS

|

PIONEERING TECHNOLOGY - UNIQUE IMPLEMENTATION

| EXACT POSITIONING AND A LARGE TEST SPACE

All 3 axes are equipped with the direct, optical path measuring system as standard. The axes and turret can be positioned to an accuracy of 1.5 μm, so even thin layers, or special testing or analytical coordinates, can be repeatedly and accurately approached. | EMBEDDED SAMPLES

The secure clamping of samples thanks to a redesigned holder with a built-in clamping force limiter, simplifies sample centering and positioning. A plate with a ball-joint even clamps specimen that cannot be held flat to prevent tilting or sliding during analysis. Available with 1, 4 or 8 holding positions and adapter rings for a large range of metric and imperial sample diameters. | SAMPLE IMAGE CAMERA

It is no coincidence that most QATM customers choose the ‘A+’ version with a built-in image camera. In a few seconds the image of the sample is shot with the additional camera (field of view 49 x 37 mm). The image provides excellent navigational support within the software, particularly in combination with DOUBLE-VIEW TECHNOLOGY, and aids enhanced documentation in the automatically compiled test report. |

| DIFFERENT TEST HEIGHTS

The unique construction of the highly-dynamic tool changer turret allows the positioning of test pieces at various heights within the test area. Innovative CAS technology protects the unit from collisions. | OPTIMIZED PERFORMANCE AND SILENCED DESIGN

Optimized testing parameters and shorter intervals for serial autofocus, brightness regulation and image analysis, facilitate unbeatable cycle times during everyday operation with the new EVO Brinell / Knoop / Vickers hardness testers; and it’s even faster than the previous model. A further benefit of the new machine concept is the emphasis on reduced noise emissions in operation and motion, making it particularly suitable for laboratory work. | IPC TECHNOLOGY / ROTATABLE INDENTER

IPC – ‘Indenter Parallel to Contour’ (optional) The operator can select the route and points for the Knoop indenter along each contour, either manually, via the software setting, or fully automatically. The compact indenter unit with a built-in rotation drive facilitates fully automated hardness testing in layers or along the edge of the workpiece. |

REVOLUTIONARY 3D OPERATING CONCEPT

3 STEPS TO THE RESULT

| 1. LOAD SAMPLES

The machine moves automatically to sample holder height. Image of sample is taken automatically. | 2. LOAD ROW

AutoSnap - Speedy Row Set-up: Drag the row of test points to the desired position. The serial Auto-Snap function corrects the starting point of the test row automatically. | 3. START TEST SEQUENCE

The test sequence is executed according to the applicable hardness testing standards. |