Uniformity and heat

Артикул: Uniformity and heat

To design and build a furnace with outstanding temperature uniformity, time-consuming calculations and simulations are required. Carbolite Gero has accumulated decades of engineering experience creating exceptional heat treatment systems.

This experience is utilised in all of standard furnaces and ovens as well as custom modifications where temperature uniformity needs to be improved even further. Some important design principles to improve the uniformity are described below.

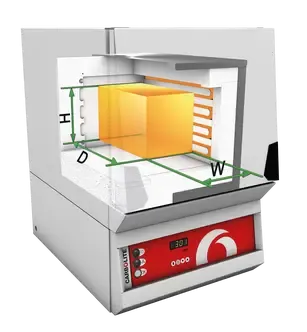

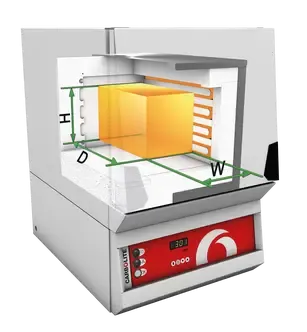

Representation of the uniform zone within a chamber furnace

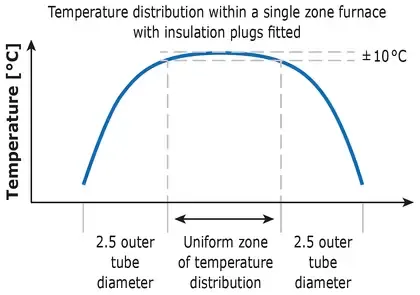

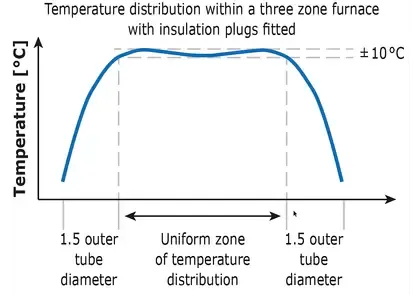

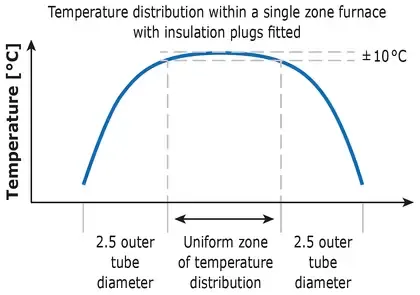

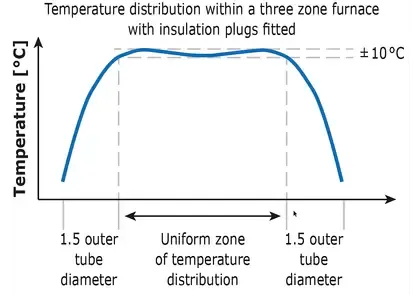

Representation of the uniform length within a tube furnace

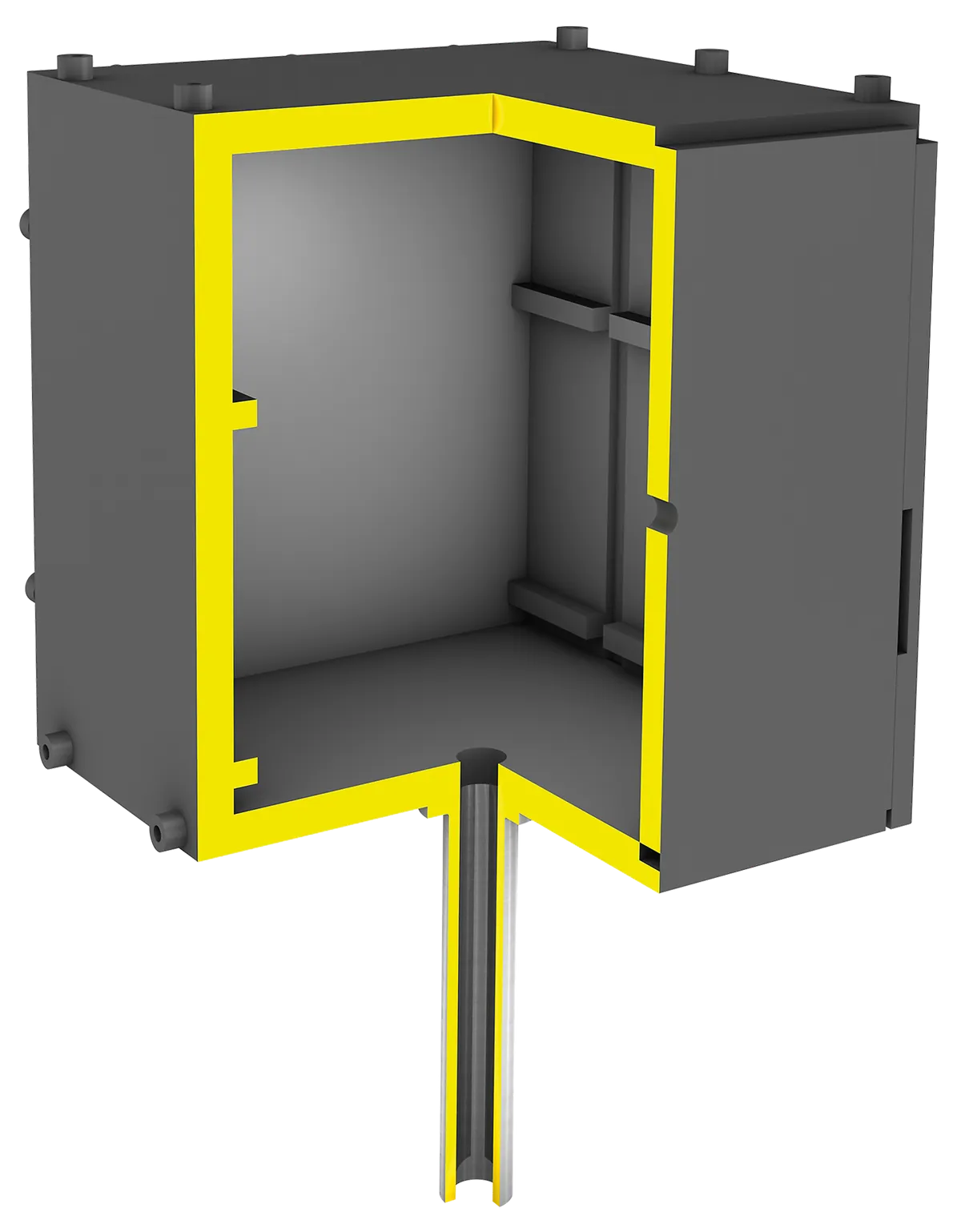

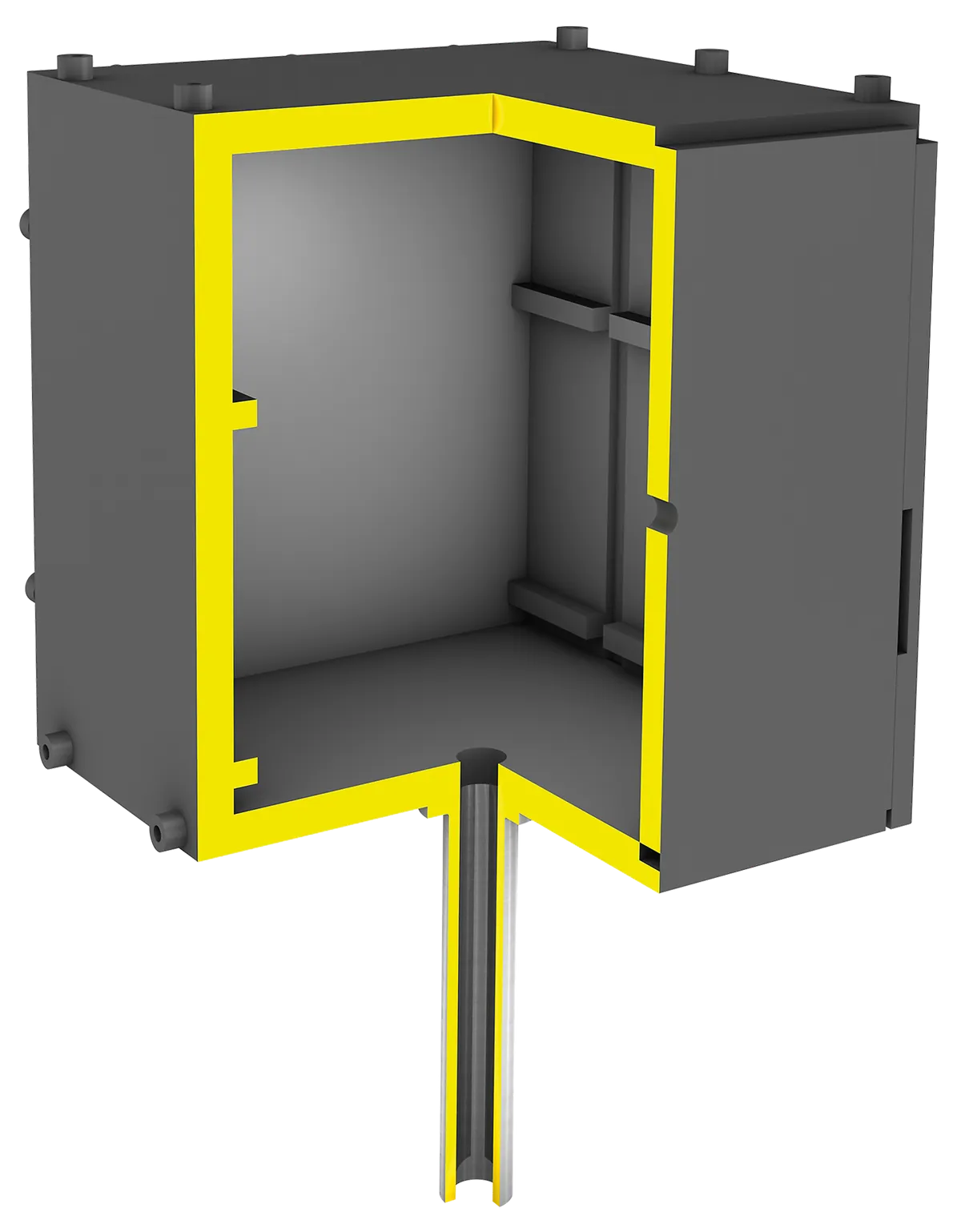

RETORTS

A closed retort is utilized to completely surround the sample specimen for operation under modified atmospheres and to improve the temperature uniformity. For example, the retort is constructed with a gas outlet for debinding applications.

MULTI-ZONE DESIGN

Multi-zone tube furnaces can compensate the temperature drop towards the ends of a tube. Three and eight zone furnaces are available.

INTELLIGENT DESIGN

For optimal temperature uniformity and distribution inside the furnace, a highly symmetric design is crucial. If a gas flow is required, the gas is preheated before flowing into the chamber.

A gas ventilation system with a sophisticated gas guiding design is provided for furnaces operating in the low temperature range.

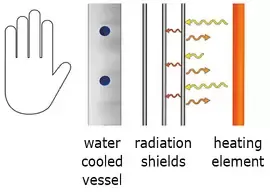

RADIATION SHIELDS & HIGH-GRADE INSULATION

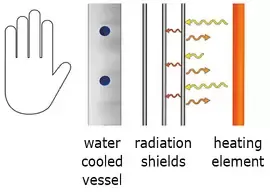

Metallic shields are utilized in the metallic furnaces to constantly reflect the heat inwards toward the sample specimen and provide insulation to the water cooled vessel. The vessel design, radiation shields, and heating elements must be highly symmetrical for optimal temperature uniformity.

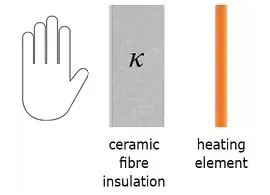

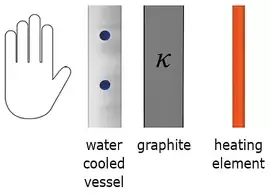

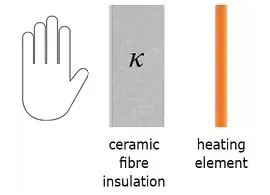

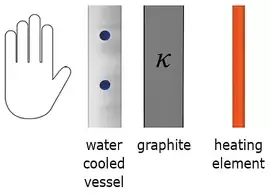

The thermal conductivity of graphite felt and ceramic fibre insulation is very low making them excellent materials for furnace insulation. The thickness and quality of the insulation materials are carefully and specifically chosen per the maximum operating temperature of the furnace.

UNIFORMITY AND HEAT - EXAMPLES

The standard V-L 180-300/10 soldering and brazing furnace is suitable for generating the lowest achievable operation pressures and highest possible temperature uniformity at the same time

Custom made three zone split tube furnace FZS 13/100/4500 with 4500mm heated length, automated opening mechanism and APM work tube

Custom made Industrial Top Hat Furnace with multi zone temperature control

Vacuum Chamber Furnace HTK GR 80/22 automatic with optional door heater for improved uniformity