Muffle furnace ABF

Артикул: ABF

The ABF Afterburner Ashing Furnace is particularly suitable for ashing larger samples or materials such as biomass, which are likely to generate substantial amounts of smoke. The furnace comprises a large main combustion chamber equipped as standard with a two tier set of sample baskets. The exhaust from the main chamber is processed through a high temperature afterburner designed to further process fumes and smoke.

STANDARD FEATURES

- 800°C maximum operating temperature - ashing chamber

- 28 Litre chamber volume

- Afterburner rated for up to 40 g carbon per ashing load

- Two tier baskets with loading tray and handle

- Programmable EPC3016P1 controller

- Independent control of afterburner temperature up to 950°C

- Silicon carbide shielded wire wound elements

- Supplied with 3-phase supply as standard

- Ethernet communications

OPTIONS (SPECIFY THESE AT TIME OF ORDER)

- A range of sophisticated digital controllers, multisegment programmers and data loggers with digital communication options is available - more information about controllers

- Over-temperature protection (recommended to protect valuable contents & for unattended operation)

- Optional floor stand

TECHNICAL DETAILS

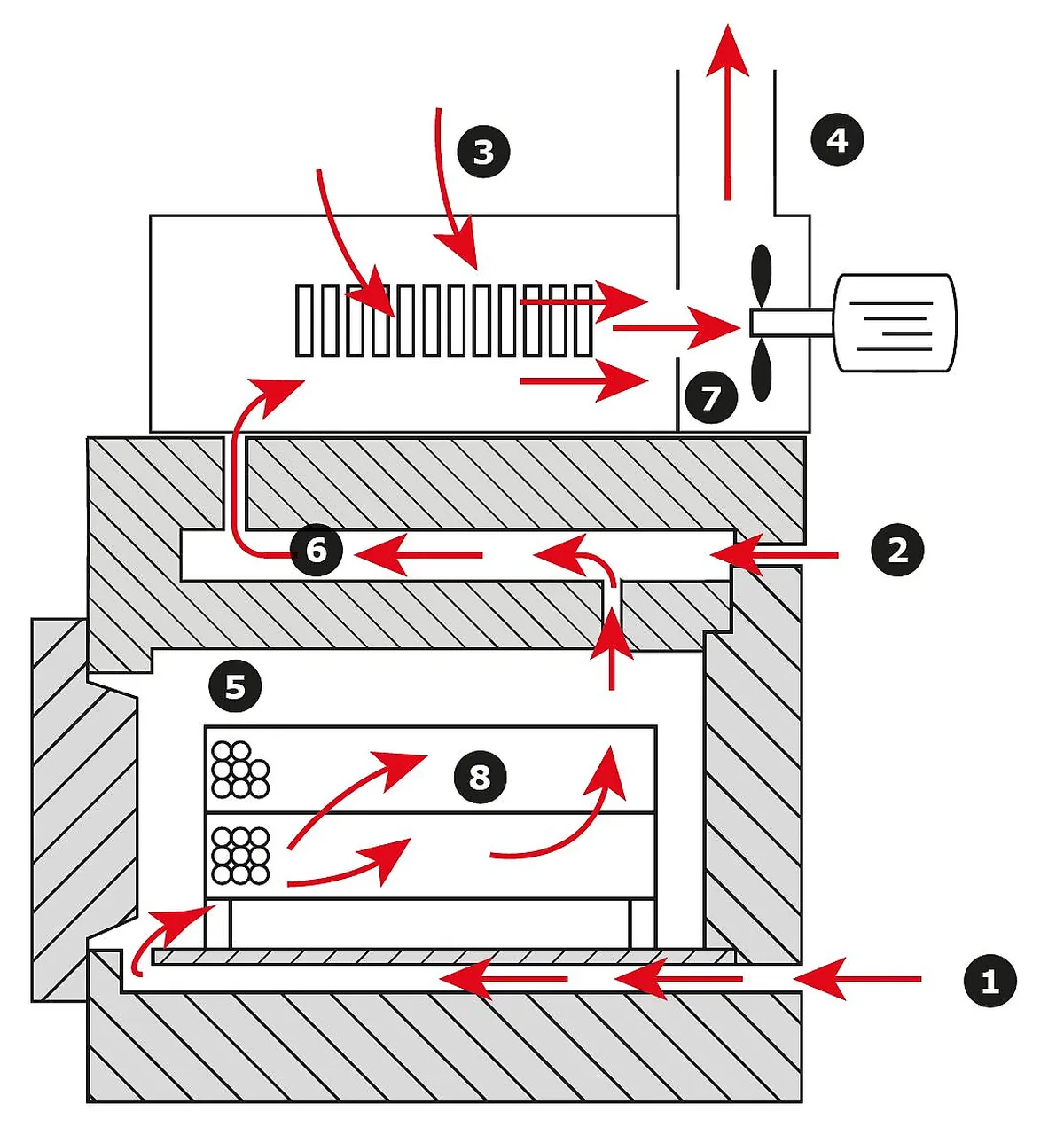

Airflow in the ABF 8/28 Ashing Furnace

- Air inlet – air is preheated before entering the chamber

- Air inlet into afterburner to ensure complete combustion

- Air inlet into plenum to cool the gases before entering the extraction fan

- Chimney

- Furnace chamber

- Afterburner

- Extraction fan

- Two tier perforated basket system