Fully automatic Brinell hardness measuring machine

Артикул: HBW 10/3000, HBW 5/750, HRC

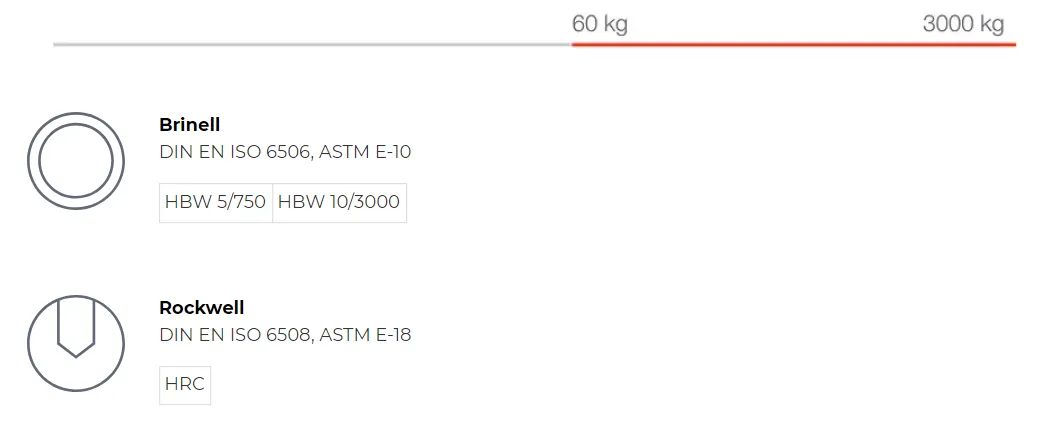

TEST METHODS & LOAD APPLICATION

Integrated conversions: DIN EN ISO 18265, DIN EN ISO 50150, ASTM E140

APPLICATION AREA

Industry: smithies, roller plants, tube rolling mills, foundries, hardening shops, stainless steel, automotive, railway, energy, steel, aviation Workpieces: rings, bars, tires, wheels, castings, open die forgings, plates, sheets, steel bottles, motor blocks, rails

HIGHLIGHTS

- standardized Brinell- and Rockwell methods acc. to EN ISO and ASTM

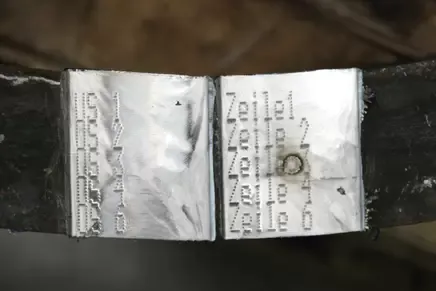

- fully automatic hardness testing cycle

- fully automatic image analysis with brightness adjustment

- applicable as inline solution in heavy laboratory construction

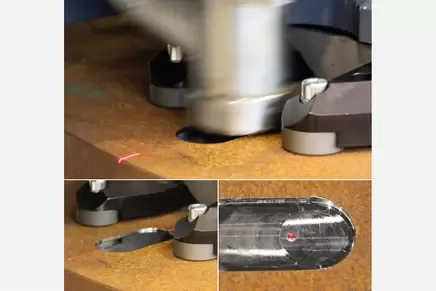

- fully automatic test point preparation

- exact milling depth adjustment

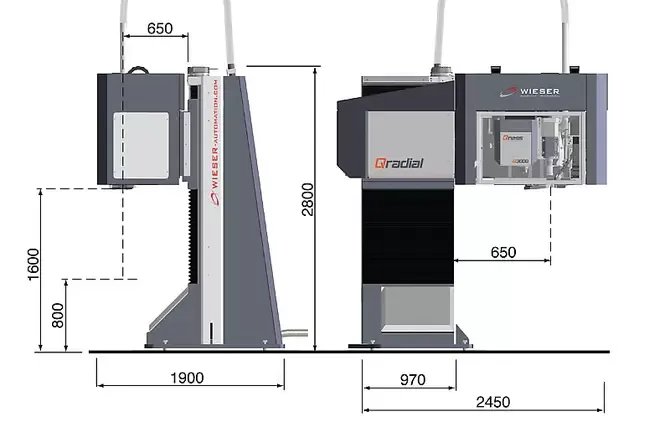

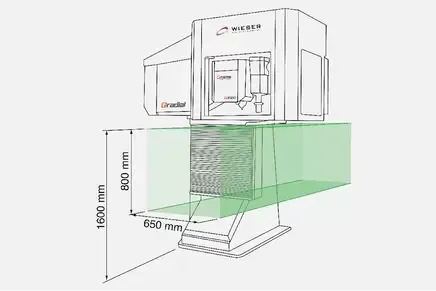

BIG TEST ROOM CONCEPT

- latest technology, innovative design

- test room for transport and magazine catch developable

- for loading the work pieces from above the test unit moves out of the feeding zone

- work piece loading possible from 5 sides

- test room max. height 1600 mm vertical path 800 mm throat depth 650 mm

CONTROL SOFTWARE QPIX T12

- Siemens S7-control

- Joystick for manual axis movement

- execution acc. to European CE-directive

- all axis servo controlled

- ringlight in bright- and dark field process

- quick auto focus

- possibility for manual 2nd test

- 12" touch screen display

- Windows 7 integrated

DATA MANAGEMENT

- numerous statistic functions: bar graph, progression, histogram

- exporting of measurement value list as "Excel" (CSV)

- A4 test protocol as PDF / direct print-out

- data storage on USB stick

- data link to ERP system and database

- order registration

- target value taking over

- actual value forwarding

OPTIONS

- marking via pin marker

- milling chip suction

- Qdas link

- ERP link

- upgradeable as inline-solution with conveyor

- ultrasonic test, VP-test (spectral analysis)

- integrated work piece

- measurement systems

- handling manipulators

- test height adjustable

- multiple test points with mean values

- test point defineable via light point