Spectrometer Epsilon Xflow

Epsilon Xflow X-ray Fluorescence Spectrometer

Continuous Real-Time XRF Analysis

The Epsilon Xflow X-ray fluorescence spectrometer is an advanced solution for continuous analysis of the elemental composition of liquid and slurry samples. With state-of-the-art technology, it ensures high sensitivity, stability, and precision of measurements.

Key Advantages of the Epsilon Xflow Spectrometer

- Continuous real-time XRF analysis

- High precision and measurement stability

- Minimal maintenance costs

- Wide range of industrial applications

Direct insight into your liquid process parameters

- Simultaneous multi-element liquid analysis

- Real-time results

- Leading EDXRF technology

- High repeatability

The Epsilon Xflow spectrometer is available as a variety of tailored solutions for specific industries, such as petrochemicals, polymers, mining, metals, food and environmental.

Overview

Blending sharpness for fuels and lubrication oils

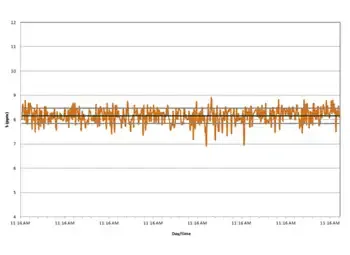

In oil refining operations, reduction of sulfur ‘giveaway’ can be achieved by improving blending sharpness to comply with Tier 3, Euro VI and other environmental regulations. Excellent repeatability at low sulfur level, visualized in the graph, ensures sharper blending and thus less giveaway.

Monitoring of liquids and liquors during ore processing

Processing ores and concentrates requires frequent and accurate monitoring to ensure maximum efficiency and minimal costs.

Epsilon Xflow enables on-line composition control of processing liquids, liquors and reagents under tough process conditions.

Mine wastewater control

To minimize environmental impact and protect life in the area around mining operations from harmful elements, constant on-line monitoring of mine wastewater quality is mandatory.

Epsilon Xflow can detect traces of toxic metals and other elements to enable immediate counteractions, preventing environmental damage and penalties.

Monitoring of key minerals in liquid food products

Nutrient and mineral fortification are essential steps during the production of many food products. Accurate fortification, combined with homogeneous mixing, will ensure that the final product always meets the label claim.

Epsilon Xflow provides on-line monitoring of key minerals controlled in liquid products, including potassium, calcium and iron.

Features

Elemental analysis within your process

X-ray fluorescence (XRF) is a non-destructive elemental analysis technology which enables you to measure your process streams without any sampling loss or chemical/physical changes. Real-time on-line XRF analysis provides fast optimization of many processes parameters and product properties.

Highly repeatable and accurate with low maintenance

The proven and robust Epsilon 3X technology used in the Epsilon Xflow is powered by the latest advances in excitation and detection technology. A well designed optical path, a wide range of excitation capabilities for light and heavier elements, and a fast high-resolution SDD detector system contribute to the power of the Epsilon 3X. The sum of all these innovations results in highly repeatable and accurate results with low maintenance.

Customizable to many production processes

The flexible design of the Epsilon Xflow makes it easily integrated into many different processes and process conditions. The solution is able to handle a broad range of environments, including harsh conditions due to:

- Temperature

- Pressure

- Viscosity

- pH value

- Corrosiveness

- Solvent polarity

Turn-key solutions

Our specialists and engineers have more than 50 years’ combined experience in the field of industrial XRF – which makes us the experts in delivering turn-key solutions globally. When installing a solution, we do not leave the site before the on-line analysis is up and running smoothly.

- Sample conditioning

- ATEX design

- Sample recovery and waste management

- Appropriate sheltering

- Process stream selection

Laboratory performance in every climate

Harsh conditions are common in plant environments. Several different features enable the analyzer to cope with harsh and changing climate conditions:

- Real-time corrections for temperature and air-pressure variations

- Heated electronics for operation in cold environments

- Extra cooling capabilities to handle tropical conditions

- Sheltering