Cutting mill SM 300: The optimum solution for laboratories and manufacturing

Артикул: SM 300

Cutting mills are suitable for the grinding of soft, medium-hard, tough, elastic, fibrous, and heterogeneous mixes of products. Thanks to the powerful 3 kW drive with high torque and RES technology, the Cutting Mill SM 300 excels especially in the tough jobs where other cutting mills fail. This mill allows for perfect adaptation to application requirements by variable speed from 100 to 3,000 min-1. A range of bottom sieves with aperture sizes from 0.25 - 20 mm is available, ensuring a defined final fineness.

HIGH TORQUE & RES TECHNOLOGY

An additional flywheel mass accounts for a very high torque which enables the SM 300 to grind many materials to analytical fineness in only one working run (RES Technology, see graphic on the right). The extra peak power derived from the flywheel mass is used to overcome potential blockages, even when grinding particularly tough materials. Additionally, the RES technology enables quick sample feeding.

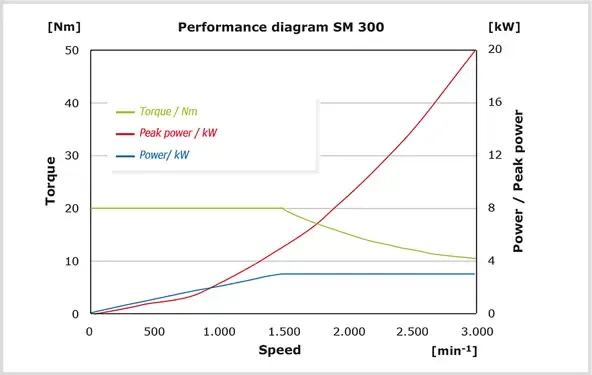

The diagram shows the torque (green) and the power (blue) of the drive as well as the temporarily achievable peak power (red) against the speed. The peak power increases over the entire speed range. That means, the higher the speed, the more power is temporarily available for the cutting events.

The diagram shows the torque (green) and the power (blue) of the drive as well as the temporarily achievable peak power (red) against the speed. The peak power increases over the entire speed range. That means, the higher the speed, the more power is temporarily available for the cutting events.

EASY OPERATION & CLEANING

SPEED REDUCTION - LESS FINES, LESS TEMPERATURE RISE

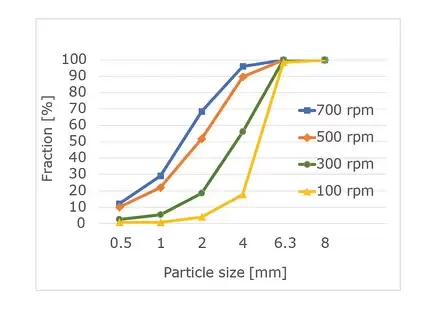

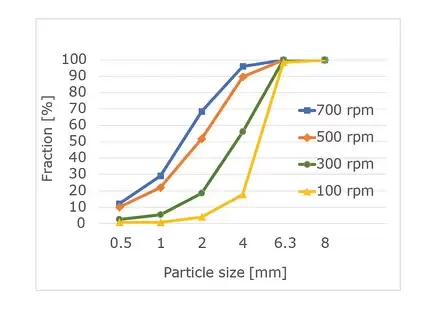

Reduction of the speed leads to a decreased fine fraction of the sample and to more particles within the desired size range. Especially for this type of application, the lowest speed of the SM 300 was reduced to 100 min-1. This is also beneficial for grinding heat-sensitive materials: reduced speed results in less energy input, preventing the sample from getting too warm during the process.

316L STAINLESS STEEL VERSION FOODGRADE

For applications like small scale production of food or cosmetics, the SM 300 is available in a stainless steel 316L foodGrade version which meets the guidelines of the food and pharma industry. It is equipped with a long-stock hopper for easy feeding of materials like cannabis plant parts. All parts in contact with the sample are made of 316L in this configuration. Optionally, the rotor blades and the cutting bars are made of a FDA-certified stainless steel which is less prone to wear under constant stress than 316L.

The unit can be equipped with an optional cyclone and a large 30 l receptacle (both stainless steel 316L) for collecting large sample amounts. Smooth surfaces lead to almost 100% sample recovery and easy cleaning.

TYPICAL SAMPLE MATERIALS

RETSCH cutting mills are suitable for a vast range of applications. Typical materials include PET preforms, aluminium slag, animal feed, bones, cables, cardboard, electronic components, feed pellets, foils, food, leather, lignite, material mixtures, non-ferrous metals, paper, pharmaceutical products, plant materials, plastic toys, plastics, polymers, refuse derived fuels, resins, rubber, spices, straw, textiles, waste, wood, etc.

TORREFACTION & BIO-COAL

Torrefaction is a thermochemical process carried out in the absence of oxygen to cause the partial decomposition of biomass. Water and volatiles are released from the biomass to leave a solid, dry material known as bio-coal. For some applications, bio coal can be used to replace traditional fossil fuels, thus helping to reduce CO2 emissions.

In this video, both RETSCH cutting mill SM 300 and the CARBOLITE GERO rotating tube furnace TSR have been used as a part of a torrefaction process to create bio-coal fuel.

The Verder Scientific companies provide solutions to support your process every step of the way, from sample preparation and analysis, to heat treatment, and more.

TECHNICAL DATA

| Applications | size reduction by cutting |

| Field of application | agriculture, biology, chemistry / plastics, engineering / electronics, environment / recycling, food, medicine / pharmaceuticals |

| Feed material | soft, medium-hard, tough, elastic, fibrous |

| Size reduction principle | shearing, cutting |

| Material feed size* | < 60 x 80 mm |

| Final fineness* | 0.25 - 20 mm |

| Speed at 50 Hz (60 Hz) | 100 - 3000 min-1 |

| Rotor peripheral speed | 4.7 - 20.3 m/s |

| Rotor diameter | 129.5 mm |

| Types of rotors | parallel section rotor / 6-disc rotor / V-rotor |

| Types of hoppers | universal, long stock |

| Material of grinding tools | stainless steel, steel for heavy-metal free grinding, tungsten carbide |

| Sieve sizes | trapezoid holes 0.25 / 0.50 / 0.75 / 1.00 / 1.50 mm

square holes 2.00 / 4.00 / 6.00 / 8.00 / 10.00 / 20.00 mm |

| Collector systems / capacities | collecting receptacle 5 l / optional: 30 l

collecting unit 0.25 / 0.5 l cyclone-suction combination (0.25 l - 30 l) |

| Drive | 3-phase asynchronous motor with frequency converter |

| Drive power | 3 kW with flywheel mass ~ 28.5 kg |

| Electrical supply data | different voltages |

| Power connection | 1-phase |

| Engine brake | yes |

| Protection code | IP 20 |

| W x H x D closed | 576 (1080 opened) x 1677 x 750 mm (with base frame and universal hopper) |

| Net weight | ~ 160 kg |

| Standards | CE |

FUNCTIONAL PRINCIPLE

Size reduction in the Cutting Mill SM 300 takes place by cutting and shearing forces. The sample comes into contact with the rotor, and is comminuted between the blades and the stationary double acting cutting bars inserted in the housing.

In the 6-disc rotor, spirally arranged reversible hard metal plates operate by cutting in sequence.

The knives of the parallel section rotor carry out comminution with a powerful cutting action. An additional flywheel mass (RES technology) on the drive shaft produces the exceptional performance of the SM 300. Thanks to the variable speed from 100 to 3,000 min-1, the SM 300 can be easily adapted to different application requirements