Glove box Carbolite Gero

- horizontal loading of the furnace chamber through the side or back wall of the glove box

- vertical loading of the furnace chamber with a furnace above the glove box. An automated mechanism moves the sample into the glove box.

GLOVE BOX - EXAMPLES

Front loader chamber furnace with glove box – HTK furnace available up to 3000°C here with automatic touch screen PLC control, high vacuum turbo pump and special convection molybdenum fan for improved uniformity at low temperatures

Front loader tube furnace with glove box - HTRH 18/100/600 with 600mm heated length up to 1800°C with an usable inner tube diameter of 88mm and two manual gas controls for Argon and formation gas (5% hydrogen and 95% nitrogen)

Detail picture of a HTK front loader furnace with glove box – Left the furnace door, the furnace loading mechanism in the middle and right the glove box air lock

Detail picture of a HTRH tube furnace with glove box – manual loading of the tube furnace by a long tray with integrated radiation shields

This pair of furnaces is built into a glove box and used in the nuclear industry as part of the process of containing nuclear waste. The furnaces are designed to meet the rigorous requirements typical in this industry.

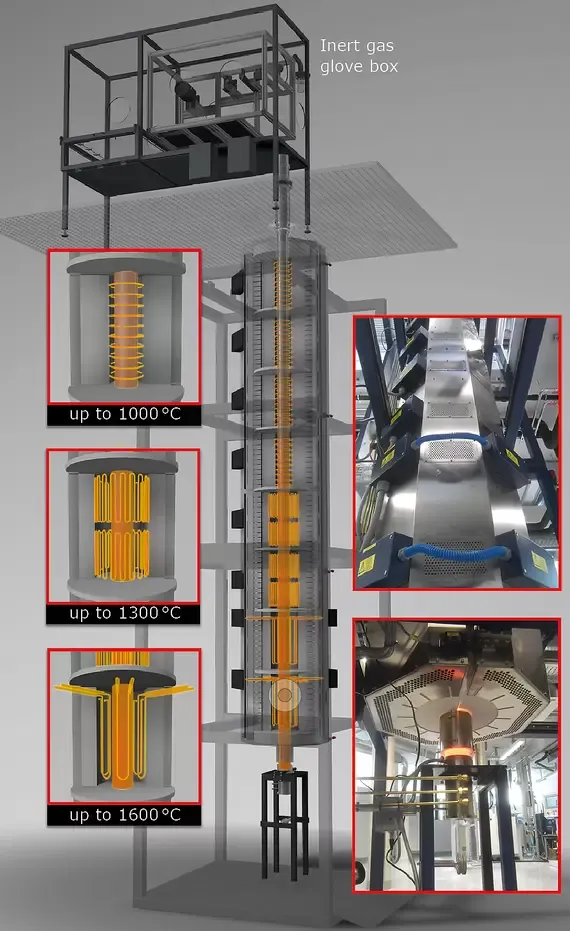

7 meters high vertical split tube furnace with glove box – HTRV-A 16/100/4000 with 4000mm heated length divided in 8 zones up to 1600°C with an usable inner tube diameter of 88mm for production of experimental advanced fibers under inert gas atmosphere