Grinding and polishing machine QPOL 250 A2-ECO

- Double wheel grinder/polisher for metallographic sample preparation

- Spin cycle feature (Cleaning Boost)

- 4.3" Touch-Screen with intuitive QATM user software

- 200 customized programs storable

- Easy cleaning/rinsing of bowl by lifting the working wheel (single-disc design)

- Variable speed of working wheel and polishing head

- Working wheel and polishing head: clockwise / counter-clockwise rotation

- Impact-proof plastic bowl

- Aluminium case, powder coated

- Economic LED illumination

CONVINCING BENEFITS

OPERATING COMFORT

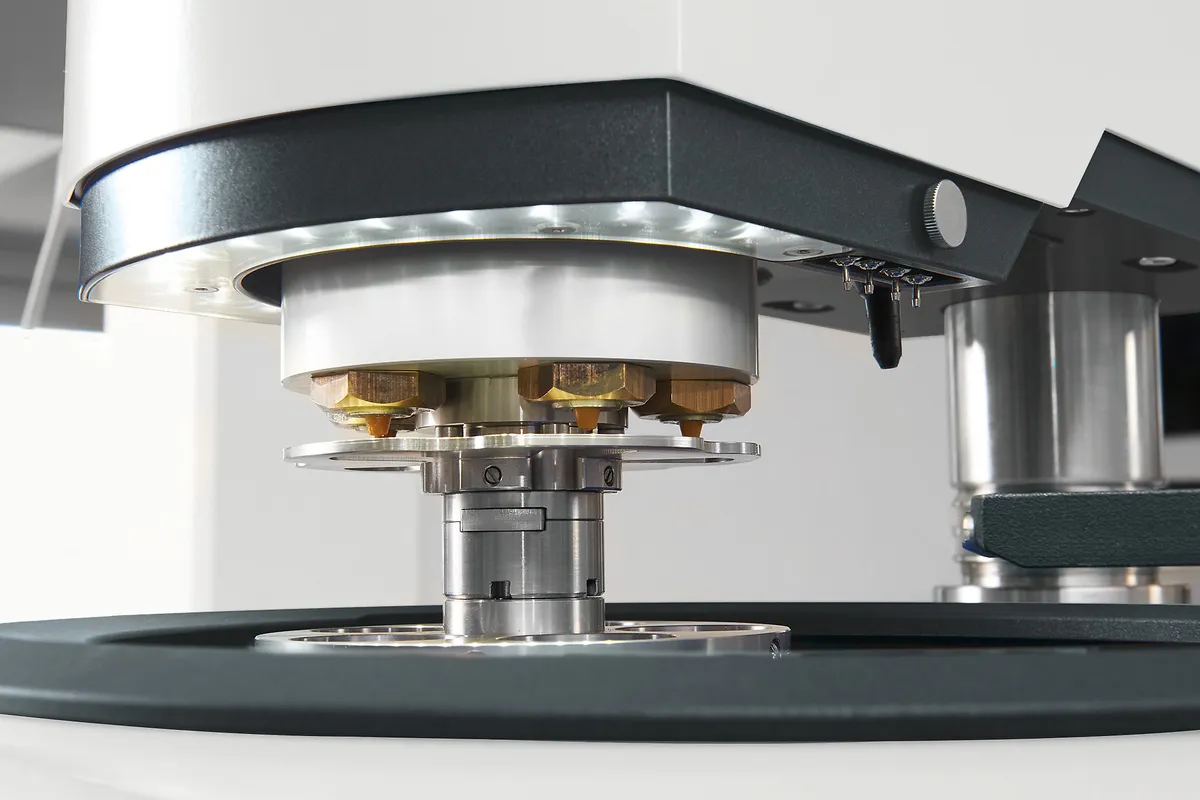

The ECO grinding & polishing head with adjustable swivelling limits is equipped with recessed grips on both sides and integrated buttons for easy swivelling and adjustment. A large gap between the working surface and the polishing head ensures convenient changing of the sample holder.

SINGLE-DISC DESIGN

After removal of the splash protection ring, the working wheel is freely accessible. The wheel is automatically arrested when placed on the new mounting system. On lifting the wheel, all parts below are accessible for easy cleaning.

ECO POLISHING HEAD

The ECO polishing head is equipped with LED illumination of the working area and a holder for the nozzles of the Qdoser ECO dosing system. Water is supplied automatically via the head.

SAMPLE HOLDERS

QATM offers a wide selection of standard sample holders in various diameters and for different applications and machines. Samples with unusual dimensions can be clamped with the help of special design sample holders.

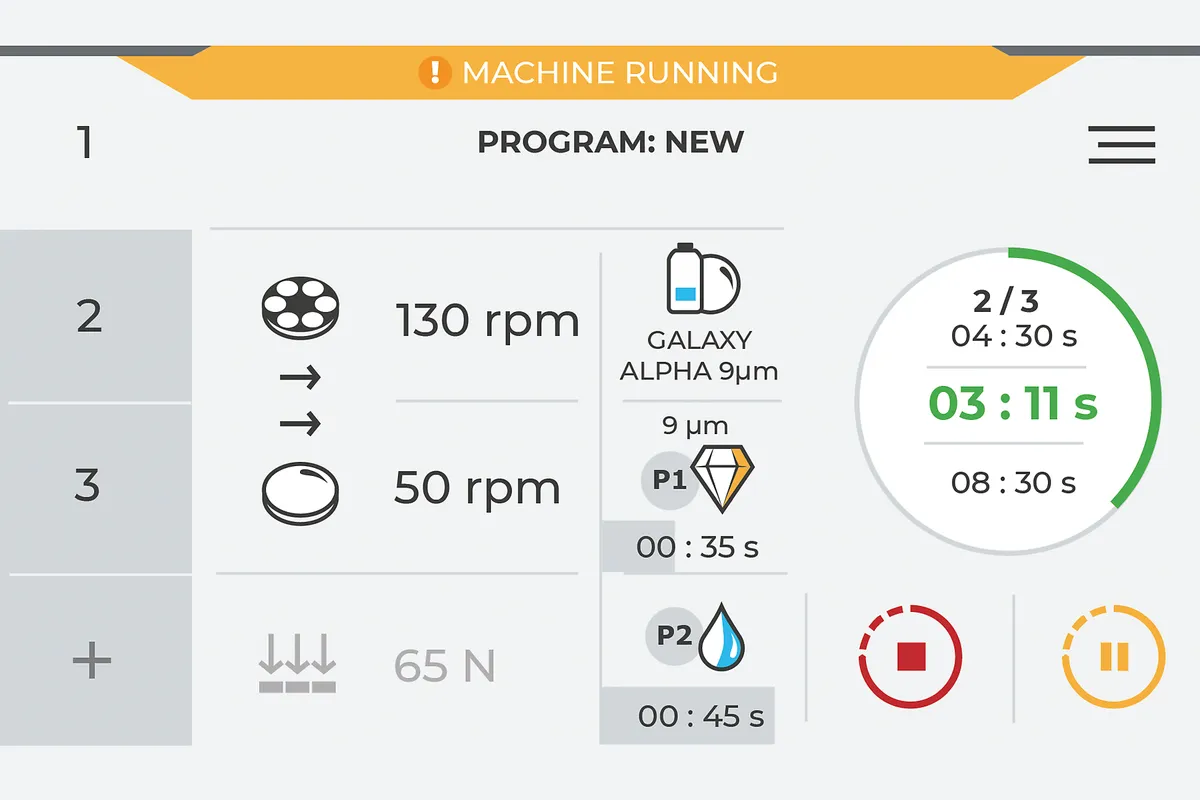

ELECTRONIC CONTROL SYSTEM

The machine is operated and programmed via the 4.3“ touch screen. Preparation methods for sample preparation may be edited and saved. It is also possible to prepare samples manually.

OPTIONAL DOSING UNIT QDOSER ECO / ONE

The automatic grinders and polishers can be combined with the fully automatic dosing system Qdoser ECO or the manual dosing solution Qdoser One, thus offering a high degree of flexibility for sample preparation and ease of use.

DOSING UNIT QDOSER ECO

The fully automatic dosing system QDOSER ECO speeds up grinding and polishing processes in the metallographic lab and is suitable for use with the Qpol 250/300 A series. Four 500 ml glass bottles with screw caps hold 3 x suspension and 1 x lubricant or 4 x Dia-Complete and can be filled via a separate lid. They are easily removed for cleaning.

The dosing nozzles are inserted into a holder attached to the head. The dosing interval is controlled via the touch screen and the software of the Qpol 250/300 A devices. The backflushing function keeps the hoses clean.

- Automatic system for

✔ 3x diamond suspension and 1x lubricant or

✔ 4x Dia-Complete

- Adjustable interval

- Reverse rinsing function

- Controlled by the control software of the Qpol 250/300 A grinders/polishers

- Suitable for all Qpol 250/300 A grinding and polishing machines

- Suspension containers refillable and removable

- incl. nozzles (inserted into a holder attached to the head)