Grinding and polishing machine QPOL XL

High sample throughput with maximum reliability: The Qpol XL is a robust and powerful powerhouse with unique removal performance and excellent preparation results. With maximum stability of body and polishing head, this unit is part of a series of QATM floor standing polishing machines.

The integrated load cell and the innovative motorized force control allow defined material removal and highest process reliability. The storage of up to 200 preparation methods is possible in the intuitive software as well as professional user management.

PRODUCT ADVANTAGES

- Working discs Ø 300/350 mm

- Powerful engines: Drive spindle 2.2 kW - Polishing head 1.1 kW

- Force control with electronic measuring system (50 - 750 N)

- Modular dosing system with up to 6 vessels and optional magnetic stirrer

- Motorized swivelling dosing arm for uniform wetting of the working disc

- Spin cycle function of the working disc (Cleaning Boost)

- Highest safety through automated safety hood

- Fast, easy and tool-free work disc change

REPRODUCIBLE PREPARATION RESULTS GUARANTEED

ROBUST ENGINEERING - FUNCTIONAL DESIGN

The basic requirements when developing the automatic grinder / polisher Qpol XL were a corpus and polishing head of utmost stability. A solid steel construction, powder-coated and a working area lined with stainless steel emphasize the sustainable, and at the same time modern and compact, machine design – made in Germany.

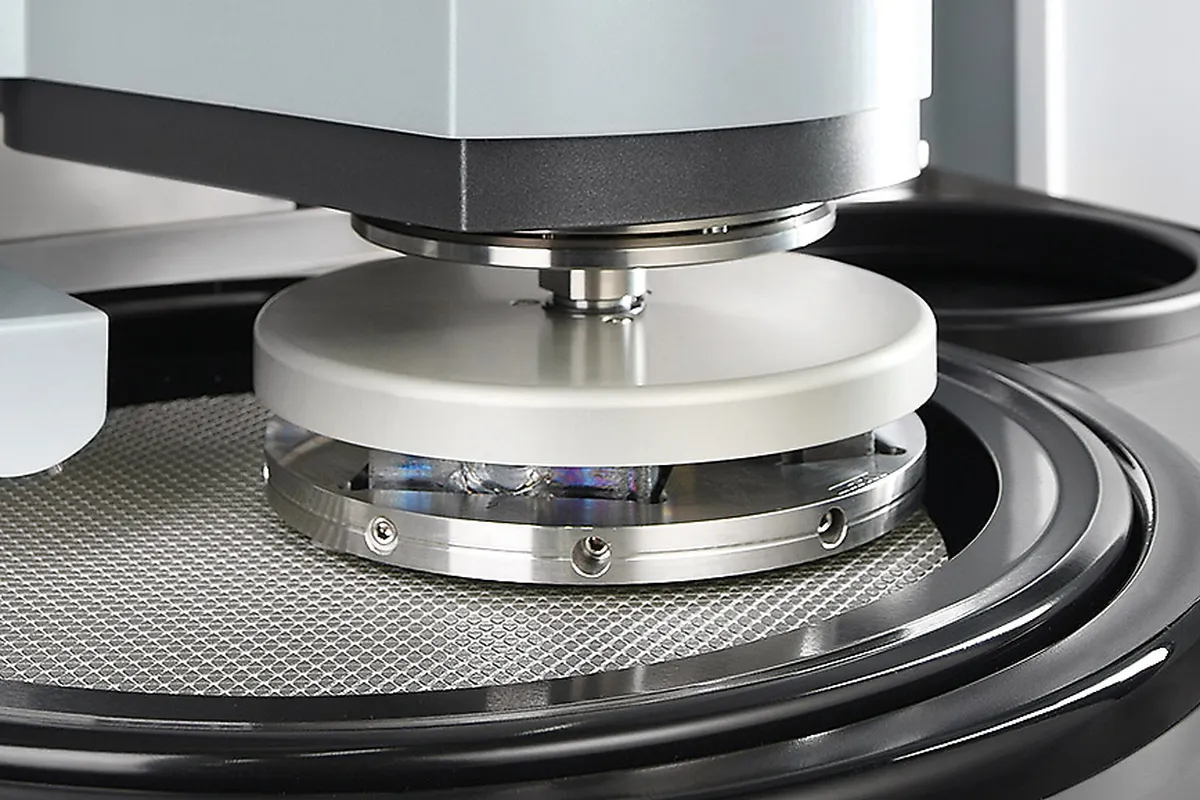

REMOVAL MEASUREMENT

The QATM Qpol XL comes with a system for precise measurement of material removal – regardless of operating time, sample type, material and hardness, you can easily monitor the material height already removed.

CONVINCING PERFORMANCE DATA

The drive motor of the working wheel has a power of 2.2 kW and the polishing head of 1.1 kW. The speed of both systems can be operated in clockwise and counter clockwise direction as well as in oscillating movement.

ADVANCED TECHNOLOGY AND MODULARITY

- Electronic measurement system for controlled press forces between 50 and 750 N.

- Integrated removal measurement

- Intuitive operating software

- Modular dosing concept with level warning

CLEANING STATION (OPTION)

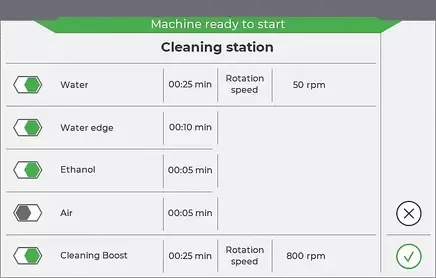

In the cleaning station specimens are automatically cleaned with water, ethanol and air or by spin cycling at up to 800 rpm (adjustable). Thus, each preparation step is finalized with a cleaning step to avoid cross contamination.

ACCESSORIES

QATM offers a wide selection of standard sample holders with different diameters and for a variety of applications and machines. Clamping of samples with unusual dimensions can be realized with special sample holders.

.

DOWN TO THE LAST DETAIL

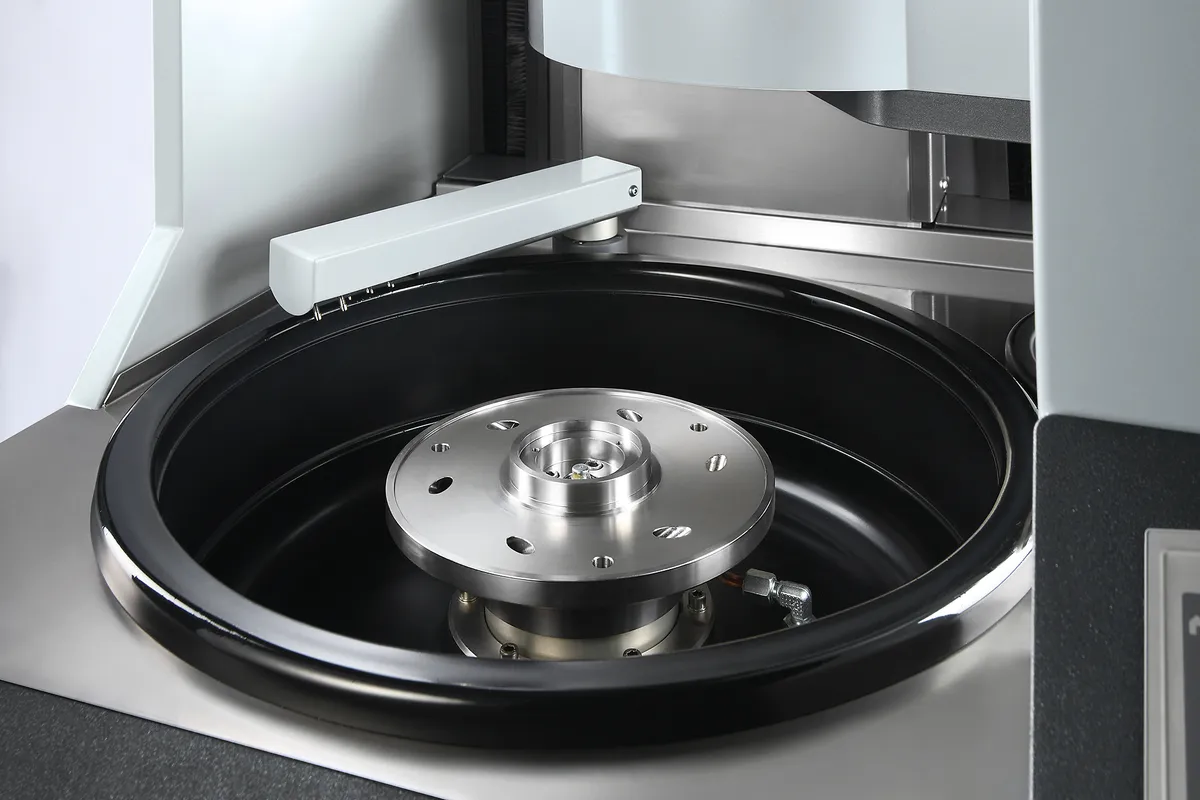

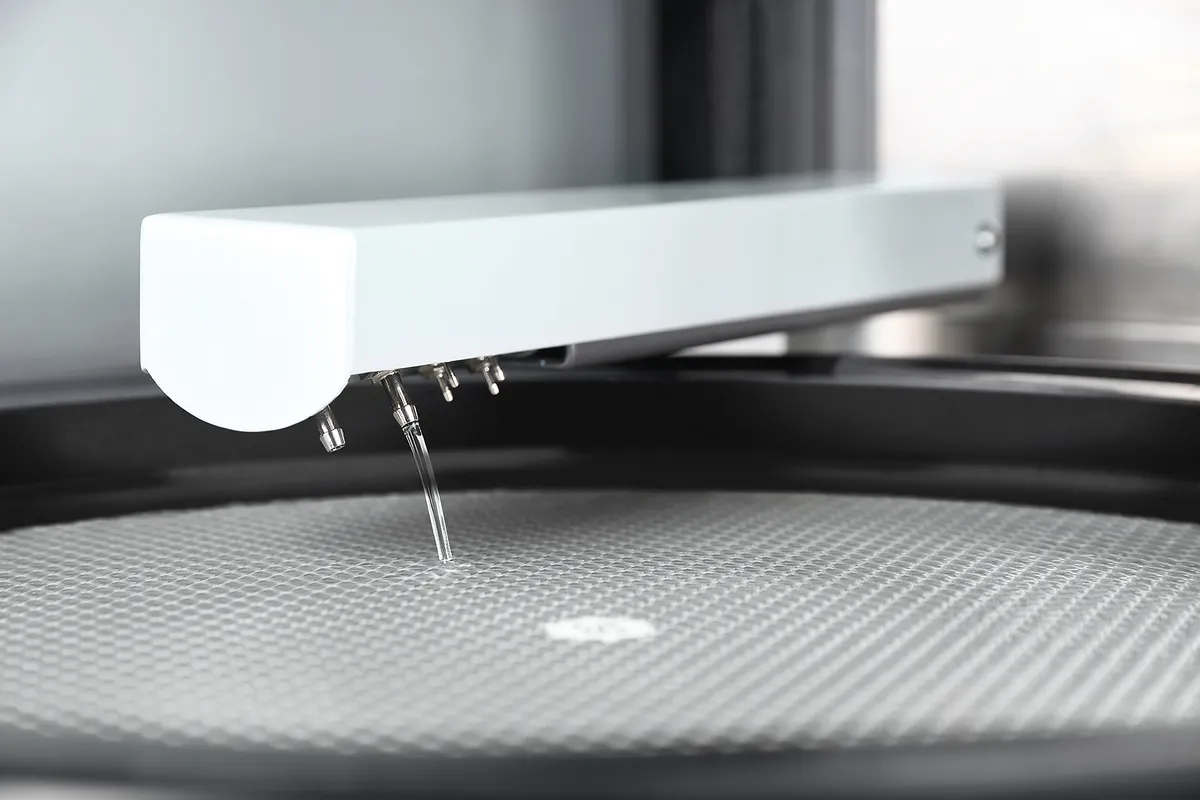

MOTORIZED SWIVELLING DOSING ARM

The fully loaded motorized swivelling dosing arm provides uniform wetting of the working wheel. It offers automatic referencing, automatic nozzle rinsing as well as good accessibility to the dosing hoses.

CONVENIENT OPERATION

The modern design of QATM’s proven control software allows for intuitive and user-friendly operation. Standard preparation methods and typical consumables are preinstalled.

Features

- 7“ touch screen

- Status display and acoustic signal

- Up to 200 programs and complete preparation methods storable

- User Account Management with variable user rights

- USB / Ethernet interface for remote maintenance and data transfer

MODULAR CONFIGURATION

MODULAR DOSING SYSTEM

The cleverly integrated dosing system accommodates up to 6 Qdoser Duran glass bottles (1L). When equipping the Qpol XL with “Preparation Dosing System”, the suspension containers can be retrofitted in packages of 2, preparing your Qpol for all future requirements. Details like the gentle illumination of the containers and the soft-closing hood top off this well-thoughtout equipment option.