Laboratory jaw crusher BB 50 from Retsch - reliability and precision in every sample

The BB 50 is the smallest model of the RETSCH jaw crusher series and has been specially designed for sample preparation in the laboratory. The compact machine fits on any laboratory bench and offers safe and convenient handling.

POWERFUL & COMPACT

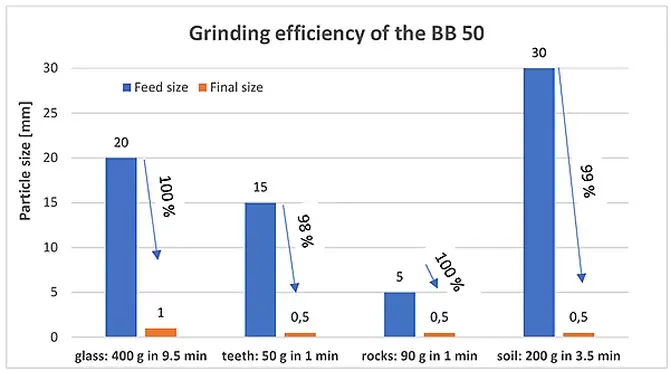

- High crushing efficiency, feed sizes up to 40 mm can be crushed to 0.5 mm

- Removable jaw for easy cleaning

- Adjustable speed allows adaptation to sample characteristics

- Wear compensation with zero-point adjustment

- Convenient operating keypad with digital display

- Memory for gap width setting

SUPERIORITY IN DETAIL

The BB 50 is designed for efficient and convenient size reduction. The variable speed can be set between 550 and 950 min-1 to adapt the crushing process to sample requirements. The possibility to reverse the rotating direction is helpful if too much sample material has been fed to the crusher causing it to block. The simple push of a button restarts the process. Due to permanently lubricated bearings and its solid design, the BB 50 jaw crusher is virtually maintenance-free.

ACCESSORIES FOR THE JAW CRUSHER BB 50

Breaking jaws and wearing plates are available in five different materials to be selected depending on the sample and the analysis to be carried out:

- manganese steel

- stainless steel

- tungsten carbide

- zirconium oxide

- steel for heavy-metal free grinding

The optional lid for the collecting receptacle of the jaw crusher ensures that the fine residues from previous samples fall on the lid and not into the receptacle which helps to avoid cross contaminations.

TYPICAL SAMPLE MATERIALS

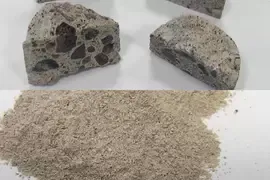

RETSCH’s powerful jaw crushers are ideally suited for preliminary crushing of construction materials, ores, granite, oxide ceramics, quartz, slag, silicon, coal, tungsten alloys, cement clinker, etc.

TECHNICAL DATA

Applications | coarse and pre-crushing |

| Field of application | agriculture, biology, construction materials, geology / metallurgy, glass / ceramics, medicine / pharmaceuticals |

| Feed material | medium-hard, hard, brittle, tough |

| Size reduction principle | pressure |

| Material feed size* | < 40 mm |

| Final fineness* | < 0.5 mm |

| Throughput* | 3 l/batch |

| Material of grinding tools | manganese steel, stainless steel, tungsten carbide, zirconium oxide, steel 1.1750 (for heavy-metal free grinding) |

| Jaw width | 45 x 59 mm |

| Gap width setting | 0 - 11 mm in increments 0.1 mm |

| Gap width display | digital |

| Zero point adjustment | yes |

| Hinged hopper | yes |

| Reverse rotating direction | yes |

| Dust extraction unit | already dust-tight |

| Central lubrication | lifetime lubrication by manufacturer |

| Process line version | process line use is possible by removing drawer |

| Collector capacity | 3 l |

| Drive | 3-phase motor with frequency converter |

| Drive power | 1.1 kW |

| Electrical supply data | different voltages |

| Power connection | 1-phase |

| Protection code | IP 20 / IP 00 at ventilation slots |

| W x H x D closed | 420 x 460 x 560 mm |

| Net weight | ~ 79 kg |

| Standards | CE |