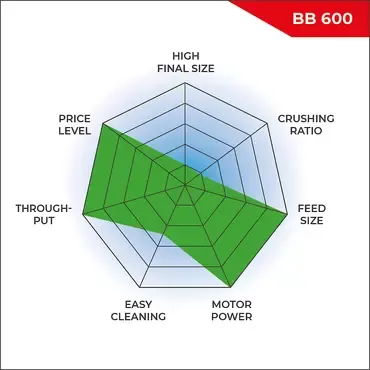

Jaw crusher BB 600 - efficiency and reliability

The Jaw Crusher BB 600 is specifically designed for accepting large feed sizes up to 350 x 170 mm. The gap width can be set stepless from 6 - 60 mm. Depending on the sample material, particle sizes down to 6 mm can be obtained in one working run, resulting in an excellent crushing ratio of 25. A throughput of up to 3500 kg/h is possible with the BB 600.

ROBUST & VERSATILE

- Excellent crushing ratio

- Continuous gap width setting

- High throughput up to 3500 kg/h

- Removable hopper with splash-back protection

- Suitable for continuous and batchwise crushing

SUPERIORITY IN DETAIL

The BB 600 achieves a throughput of up to 3,500 kg per hour. For batchwise processing, the jaw crusher is equipped with a 30 l collecting receptacle.

- manganese steel

- steel for heavy-metal-free grinding

- NiHard4 steel.

PROCESS-LINE VERSION

Due to the low installation height of 1 meter the BB 600 is ideally suited for continuous operation in automatic installations and sampling stations.

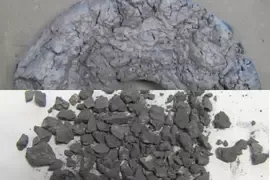

TYPICAL SAMPLE MATERIALS

TECHNICAL DATA

| Applications | coarse and pre-crushing |

| Field of application | chemistry / plastics, construction materials, engineering / electronics, environment / recycling, geology / metallurgy, glass / ceramics |

| Feed material | medium-hard, hard, brittle, tough |

| Size reduction principle | pressure |

| Material feed size* | < 350 x 170 mm |

| Final fineness* | < 6 mm |

| Throughput* | 3500 kg/h |

| Material of grinding tools | manganese steel, steel for heavy-metal free grinding, NiHard4 |

| Jaw width | 400 x 240 mm |

| Gap width setting | 6 - 60 mm with spacer plates |

| Dust extraction unit | no |

| Central lubrication | no |

| Process line version | optional |

| Collector capacity | 30 l |

| Drive | 3-phase motor |

| Drive power | 15 kW |

| Electrical supply data | different voltages |

| Power connection | 3-phase |

| Protection code | IP 55 |

| W x H x D closed | 925 x 1600 x 1370 mm |

| Net weight | ~ 1350 kg |

| Standards | CE |

FUNCTIONAL PRINCIPLE

The Jaw Crusher BB 600 is a robust and powerful jaw crusher.

The feed material passes through the no-rebound hopper and enters the crushing chamber.Size reduction takes place in the wedge-shaped area between the fixed breaking jaw and the moveable breaking jaw driven by an eccentric drive shaft. The elliptical motion crushes the sample which then moves downwards under gravity.

On reaching the discharge gap width, it falls into a removable collector or, for continuous applications, on a conveyor belt, vibratory feeder or sampler.