Rotary reactor tube furnace range TSO

OVERVIEW

LEADING HEAT TECHNOLOGY

The oscillatory motion of the TSO rotary reactor tube furnace helps increase the surface area of the sample material exposed to the atmosphere within the vessel, helping to speed up reaction times and improve the overall yield.

HIGH QUALITY HEATING ELEMENTS

- Excellent temperature uniformity

- Fast heat-up and cool-down rates

- Unsurpassed temperature uniformity along the entire heated length

- Low energy consumption

- Low external case temperature

- Designed for longevity

TEMPERATURE CONTROL & COMMUNICATIONS

TSO rotary tube furnaces are equipped with ethernet communications and a programmable controller with 24 segments as standard:

- Single zone furnaces fitted with Carbolite Gero EPC3016P1 controller

- Three zone furnaces fitted with Carbolite Gero CC-T1 touch-screen controller

OPTIONS

- Over-temperature protection (recommended to protect valuable contents and for unattended operation); 1600°C models are equipped with this option as standard

- A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications.

ACCESSORIES

MODIFIED ATMOSPHERE

The Carbolite Gero TSO rotary reactor tube furnace range may be equipped with gas connections to accommodate modified atmosphere applications.

OPTIONS

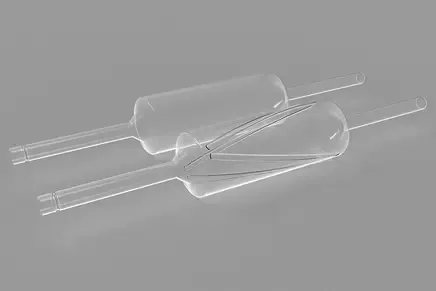

- Standard or fluted reactor vessels

- Gas connection kit to enable operation under modified atmospheres

- Inert gas package modules allow for the use of up to 3 non-reactive gases (available with either manual or automatic control)

Rotary reactor vessel

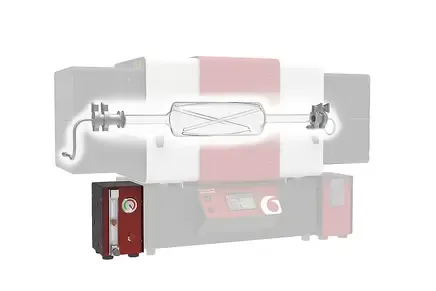

Rotary reactor inside of TSO furnace

MOUNTING CONFIGURATIONS

FURNACE BODY ON TOP OF CONTROL BOX

Configuration for heated lengths up to 600 mm