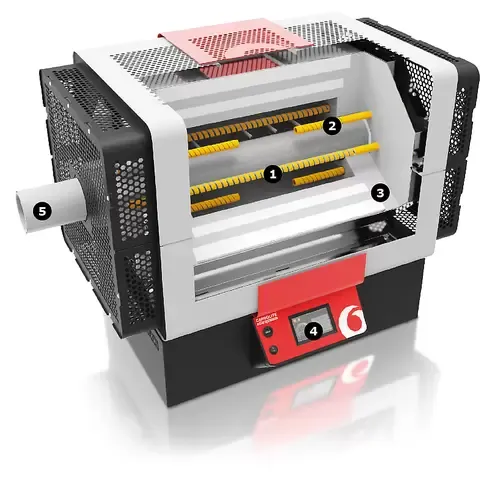

Gradient tube furnace range TG

LEADING HEAT TECHNOLOGY

- Excellent temperature uniformity

- Fast heat-up and cool-down rates

- Unsurpassed temperature uniformity along the entire heated length

- Low energy consumption

- Low external case temperature

- Designed for longevity

TEMPERATURE CONTROL & COMMUNICATIONS

TG gradient furnaces are equipped with RS485 communications and a Carbolite Gero EPC3016P1 programmable temperature controller with 24 segments for each heated zone as standard..

OPTIONS

- Over-temperature protection (recommended to protect valuable contents and for unattended operation)

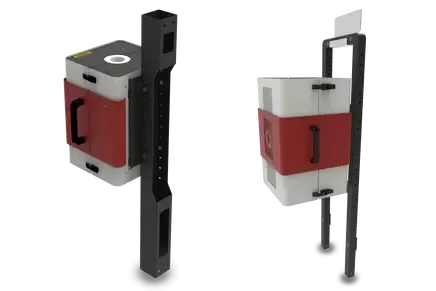

MOUNTING CONFIGURATIONS

TG gradient tube furnaces are supplied mounted on top of the control box. The furnace body can easily be detached and separated for remote operation.

This configuration includes a 2 metre cable (furnaces with 125 mm Ø incl. plug and socket) between the furnace body and control box. This flexible arrangement allows for easy conversion to optional mounting arrangements e.g. attaching to a vertical stand, a mounting bracket or inside a fume cupboard.

FURNACE BODY ON TOP OF CONTROL BOX

Configuration for heated lengths up to 600 mm

DETACHABLE FURNACE BODY

Easy conversion to optional mounting arrangements

OPTION: 4 M CABLE EXTENSION

4 m long extension results in a total of 6 m between furnace body and control box (125 mm Ø models include plug and socket)

OPTION: VERTICAL STAND

Vertical mounting stand for the furnace body

OPTION: MOUNTING BRACKET

Used to mount the furnace body to customer equipment

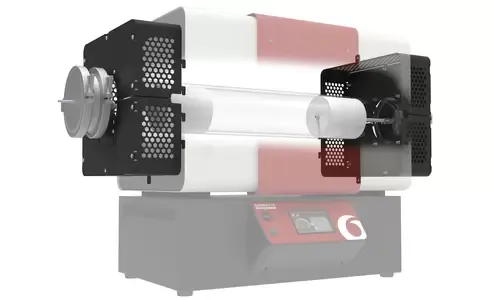

MODIFIED ATMOSPHERE & VACUUM EQUIPMENT

Carbolite Gero tube furnaces may be equipped with many different options to accommodate modified atmosphere and/or vacuum applications.

OPTIONS

- A range of additional work tubes, end seals and complete work tube packages

- Vacuum packages with a choice of rotary vane pumps or turbomolecular pumps

- Inert gas package modules allow for the use of up to 3 non-reactive gases (available with either manual or automatic control)

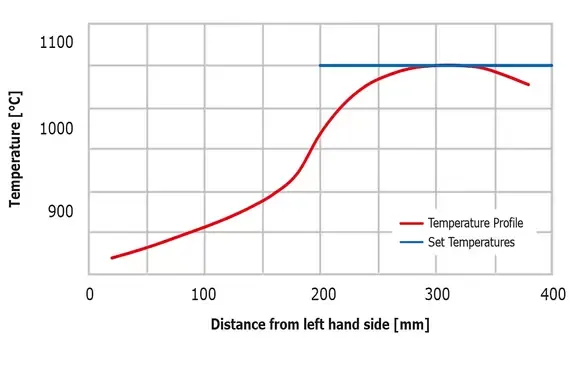

HEAT TREATMENT IN A GRADIENT TUBE FURNACE

A sample could be moved between two temperature zones to achieve a desired heat cycle without waiting for a single zone furnace to heat or cool.

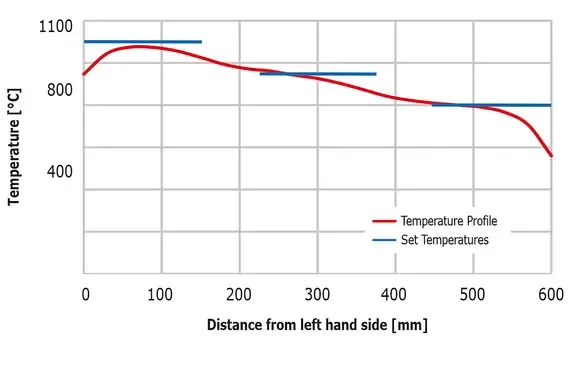

Temperature Gradient, Horizontal TG2 12/125/425.

80 mm OD worktube.

Setpoints: zone 1: off, zone 2: 1100 °C

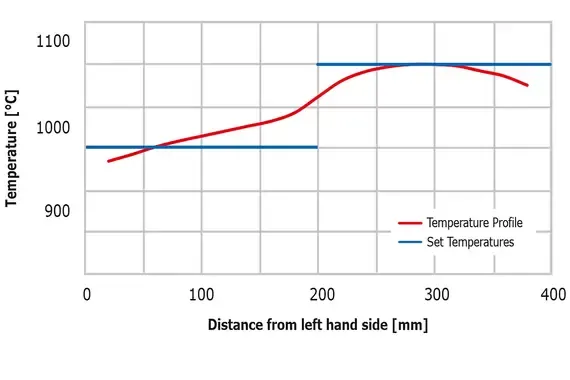

Temperature Gradient, Horizontal TG2 12/125/425.

80 mm OD worktube.

Setpoints: zone 1: 1000 °C, zone 2: 1100 °C

Temperature Gradient, Horizontal TG3 12/60/600.

60 mm OD worktube.

Setpoints: zone 1: 1100 °C, zone 2: 950 °C, zone 3: 800 °C

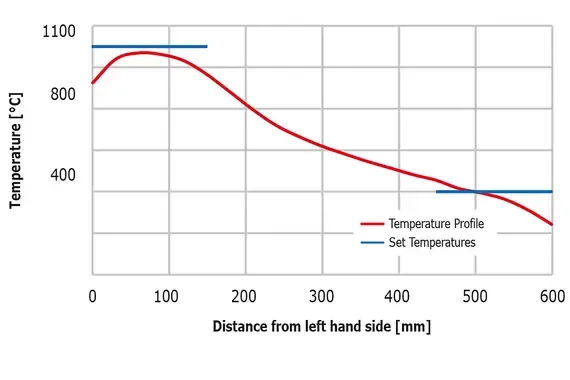

Temperature Gradient, Horizontal TG3 12/60/600.

60 mm OD worktube.

Setpoints: zone 1: 1100 °C, zone 2: off, zone 3: 400 °C

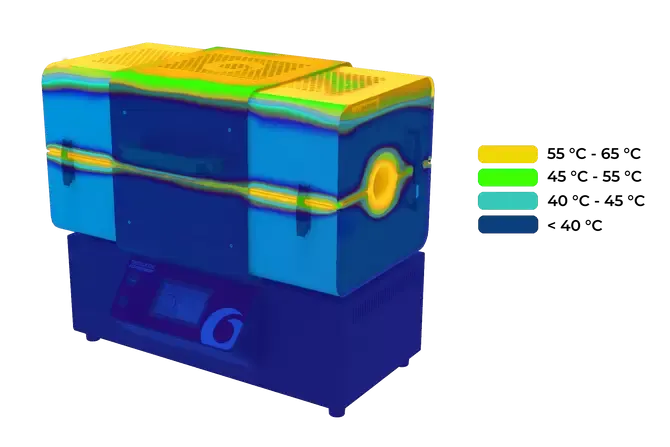

LOW CASE TEMPERATURE

Carbolite Gero tube furnaces are designed with user safety in mind.

The robust construction and high-quality thermal insulation ensure that external case temperatures are much lower than other models.

Not only does this help mitigate the risk of injury to the operator, the reduction in the amount of heat escaping the furnace ensures a comfortable working environment, and also means that less energy is wasted during use. When the heat is on, Carbolite Gero can help you keep a cool head!

- Час нагріву вимірювали під час нагрівання до температури на 100 °C нижчої за максимальну за порожньої робочої кварцової трубки зі встановленими теплоізоляційними заглушками

- Швидкість нагріву при використанні керамічної робочої трубки обмежена 5 °C/хв

- Потужність підтримання температури вимірювали за температури постійної роботи

- Температурний градієнт вимірювали з використанням теплоізоляційних заглушок

- Рекомендована температура безперервної роботи на 100 °C нижча за максимальну

- Усі печі обладнані термопарами типу N