Macro hardness tester QNESS 250 / QNESS 750 / QNESS 3000 E EVO

A hardness tester for all purposes: no matter if operated in a laboratory or in a rough production environment.

The fixed component support and extra-large test table area allow hardness testing of even the largest components.FASTER TEST METHOD CHANGE-OVER

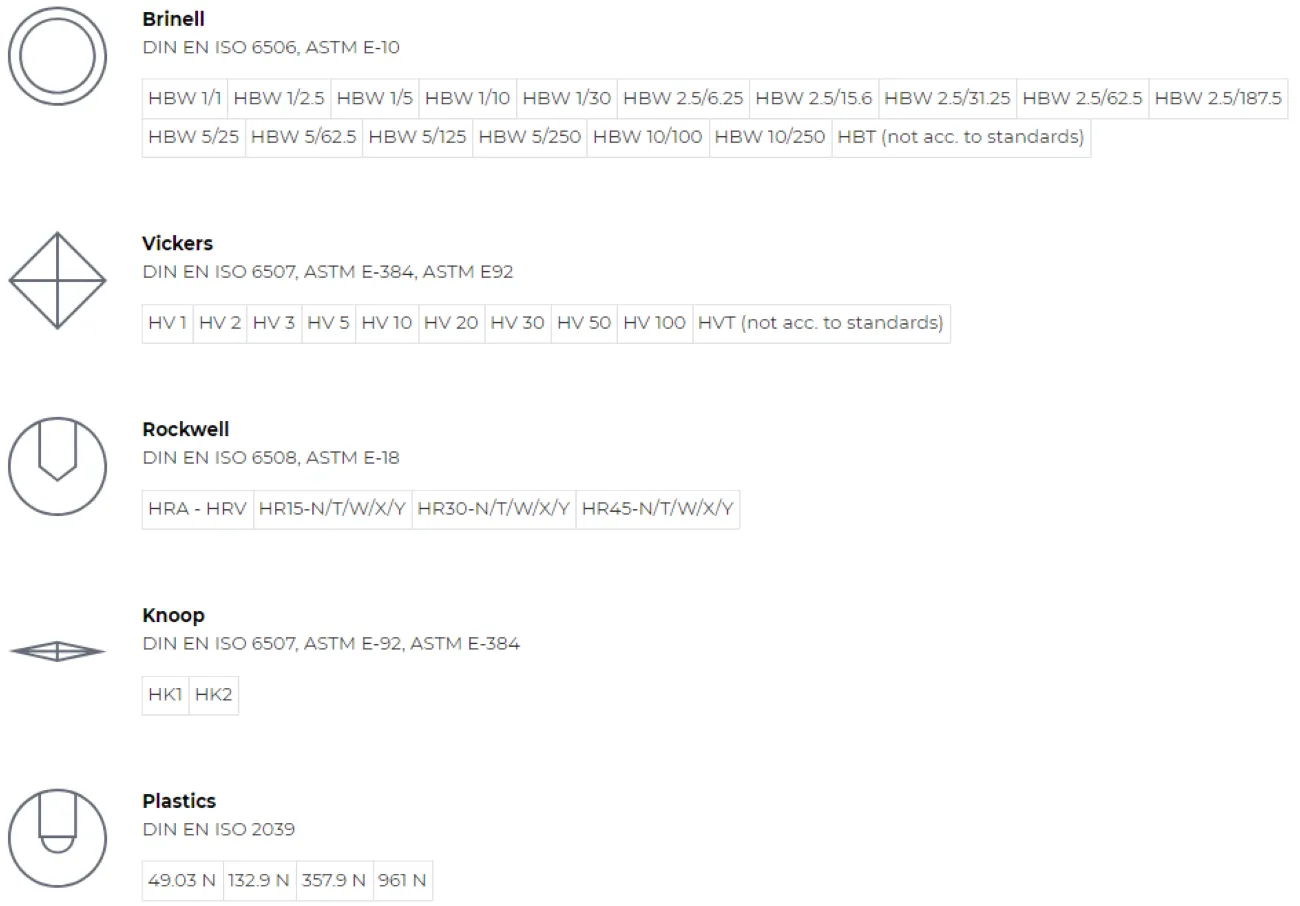

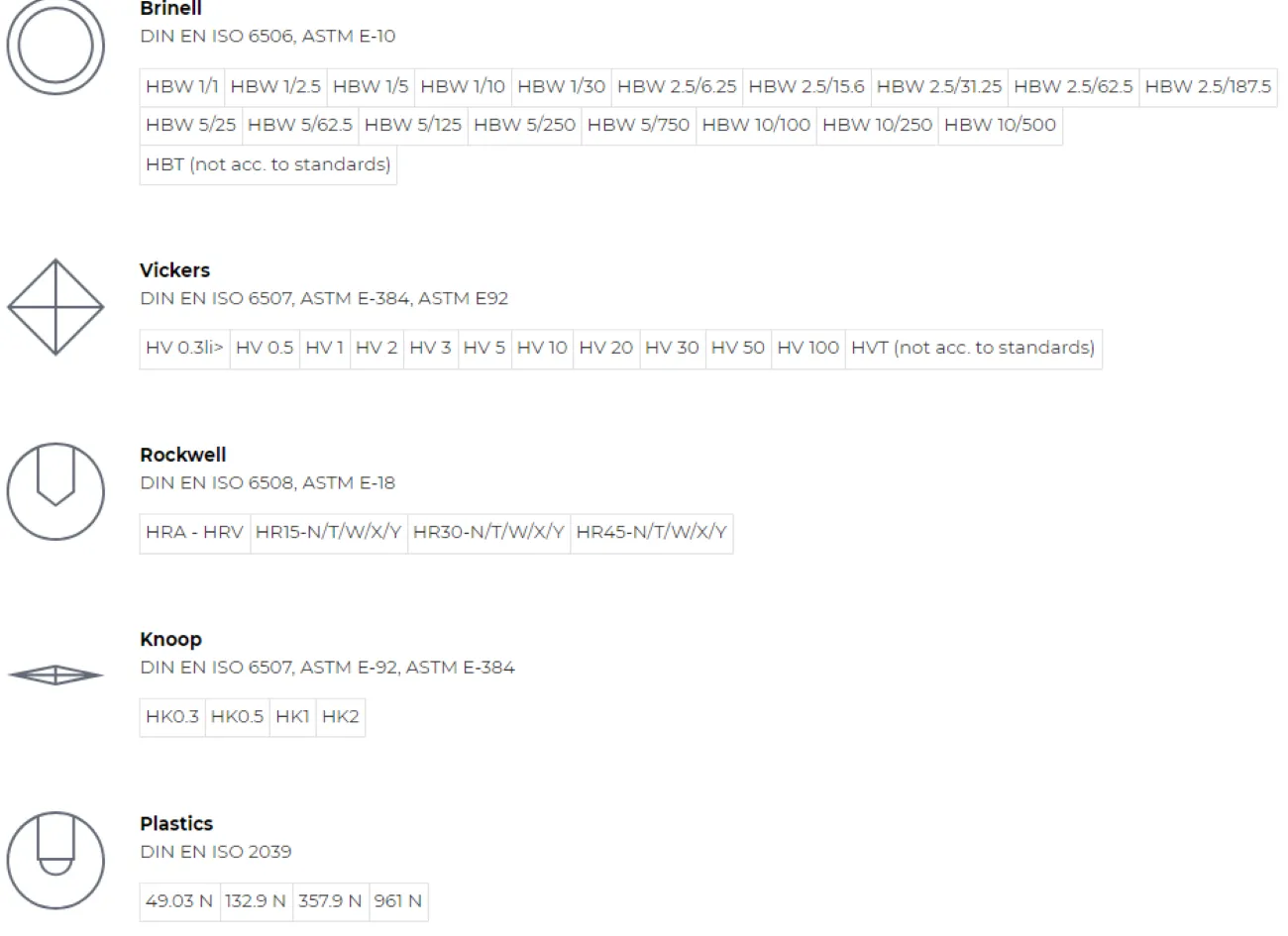

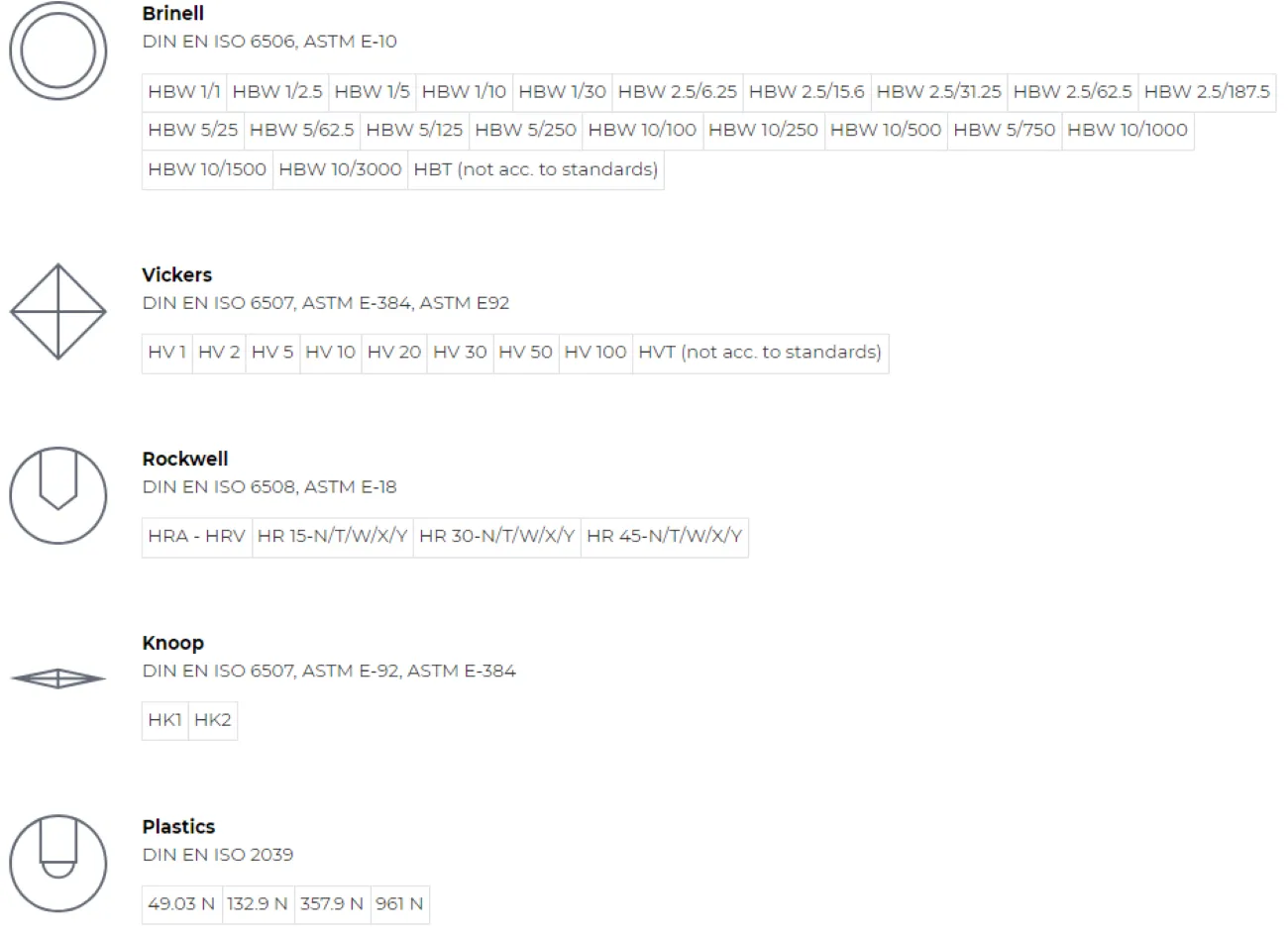

TEST METHODS & FORCE APPLICATION

Qness 250 E

Qness 750 E

Qness 3000 E

UNIQUE INSTRUMENT FEATURES

DYNAMIC HEIGHT ADJUSTMENT The dynamic height adjustment enables comfortable positioning control via potentiometer (8 mm/s). Using the 2-hand-safety device allows a moving speed of up to 17 mm/s (included with E variant). |

WORKPIECE RECOGNITION Workpiece recognition with motorized height adjustment facilitates a high test head movement speed of 17 mm/s. Sensor technology enables the workpiece to be recognized and the bracing speed to be reduced accordingly to protect the device and workpiece. |

SWIVELING DOWNHOLDER No long tool changeovers for inaccessible test positions. The downholder can be swivelled in and out via manual or motorized action, as required. Furthermore, the clamping elements can be changed easily and adapted to suit the customer‘s component. |

SWIVEL-ACTION MACHINE TABLE Unique operating convenience for large, awkwardly-shaped molded and formed components and workpieces. The work table, optional with the M and E versions, can be tilted up to 5° – including built-in grips – no extra workpiece clamping necessary! |

MAXIMUM CLAMPING SAFETY High-performance induction motor in the E version facilitates a workpiece clamping force of up to 3500 kg. Clamping power is adapted to the test method and is automatically set to be greater than the test force. Operators do not need to set levels and can rely on the device to guarantee safe, optimized adaption. |

ENLARGED TEST HEIGHT If the 510mm height of the test room is still not enough for especially large, bulky or difficult-to-clamp items, on request QATM can provide an even taller machine frame. The robust steel frame can be produced in customized dimensions. |

HIGHLY ACCURATE RESULTS IN ULTRA-SHORT TIME

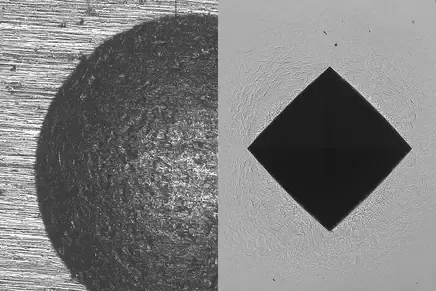

EXCELLENT IMAGE QUALITY The optics system has been completely redeveloped. It was built on site in the cleanroom at the QATM plant and benefits from the company’s comprehensive expertise. All the new devices share one universal microscope system covering all the necessary visual ranges between 0.1 mm and 8 mm in maximum clarity and contrast. The QATM system guarantees uniform illumination across the entire image, regardless of the degree of magnification, and without dark edges. |

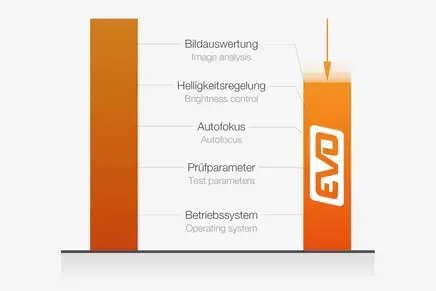

REDUCED CYCLE TIMES The new EVO product line guarantees optimized test parameters, a faster Windows 10 PC, much shorter serial autofocus times, significantly faster regulation of brightness and image evaluation, all of which contributes to far more rapid cycle completion times in everyday hardness testing – with even quieter operating noises. |

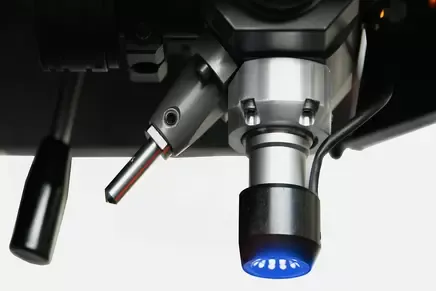

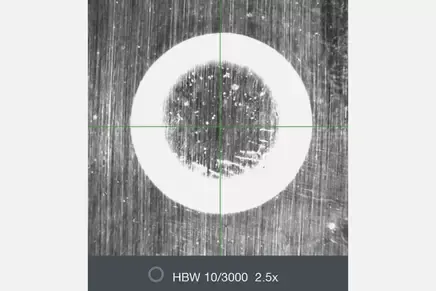

XLED BRINELL EVALUATION LENSES XLED illumination modules revolutionize the analysis of Brinell indentations. Due to beading on commercially available lenses, soft Brinell indentations in particular can be subject to imprecise gauging results. In contrast, XLED lenses guarantee precise and repeatable measurements, regardless of material type and hardness, due to direct and wide-extension illumination. |

UNLIMITED SUITABILITY FOR INDUSTRIAL APPLICATIONS

ETHERNET INDUSTRIAL CAMERAS High-quality CMOS 5-megapixel cameras with Ethernet data transfer define the current industrial standard. Unlike other camera systems, a far higher transmission stability is possible here. Additionally, the PC and hardness tester can be set up remotely at great distances from each other. This is ideal in manufacturing environments in which the control infrastructure is installed in external switch cabinets. |

FREELY ADJUSTABLE OPERATING DISPLAY The 12” ultra-flat, capacitive touch display can be raised, lowered and tilted smoothly via ball-and-socket joints for ergonomically optimized use. |

OPTIMIZED TEST HEAD DESIGN A range of clamping and holding elements can be configured to suit tooling requirements. The optional transparent collision guard can protect tools on the device from damage while ensuring an unrestricted view of the test cell interior. |

FOR YOUR TESTING NEEDS

We offer the very best solutions for your testing needs - from workpiece bracing, extended test area and possibilities for automation to software adaption. |

Manually cross slide |

Extended test area

|

Dark field illumination (option) |

Workpiece bracing |

Ring light for soft materials (Option)

|