Large industrial ovens / furnaces Carbolite Gero

HEAVY DUTY APPLICATIONS

PRODUCTION FURNACES

LOADING OF HEAVY LOADS

LARGE INDUSTRIAL OVENS / FURNACES - EXAMPLES

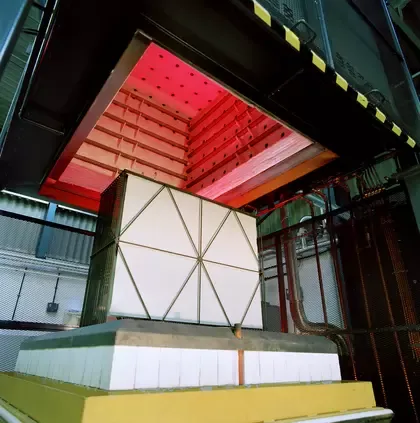

Custom designed elevator hearth furnace up to 1300°C for industrial production

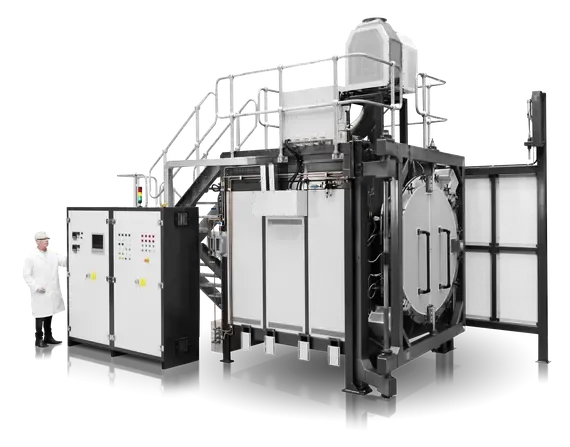

Custom designed retort furnace for carbonisation in an argon atmosphere with 1 cubic metre working volume. Inconel retort with 1100°C maximum temperature and forced cooling system to allow a 24 hour cycle time. Dual hinged retort door arrangement. Supplied with electric stacker truck and graphite pallet system

Custom designed top hat furnace with twin bell retorts and digital six channel data logger

Moving wall coke test oven up to 1300°C for 227 kg load

Custom designed twin bogie elevator hearth furnace, up to 1700°C, for sintering boron nitride ceramic parts

Custom designed three chamber vertical shaft oven for the aerospace industry