Mixer mill MM 400 - for precise grinding, mixing and homogenization

The Mixer Mill MM 400 is a true multipurpose mill designed for dry, wet and cryogenic grinding of small volumes up to 2 x 20 ml. It mixes and homogenizes powders and suspensions with a frequency of 30 Hz within seconds – unbeatably fast and easy to operate.

THE MOST VERSATILE ALL-ROUNDER OF BALL MILLS

- Max. speed 30 Hz

- Horizontal oscillation causes strong impact effects for effective sample processing

- Up to 8 mm feed size and 5 µm final fineness

- 2 grinding stations for jars of min 2 ml and max 50 ml, adapter for 10 x 2 ml single use vials and 4 x 50 ml conical centrifugation tubes

- Steel jars can be precooled manually in liquid nitrogen

- Calibrated speed and time, small benchtop model, storable SOPs and cycle programs, 7 different jar materials

PERFORMANCE AND DESIGN

- Powerful size reduction and homogenization by impact and friction with up to 30 Hz

- Equipped with 2 grinding stations for up to 20 samples per run

- Memory for 12 Standard Operating Procedures (SOP) and 6 program cycles

- Convenient touch display, significant noise reduction

UNMATCHED VERSATILITY

- 3 different grinding modes: dry, wet or cryogenic

- Mixes powdered sample and binder in plastic vessels prior to pelletizing, e. g. for XRF analysis

- Suitable for research applications such as mechanochemistry or for biological cell disruption by bead beating

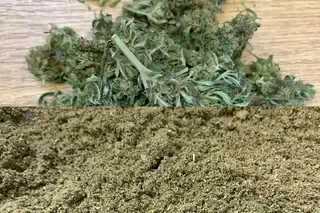

- Extraction of pesticides (QuEChERS) and herbal ingredients

SOLUTIONS FOR BIOLOGICAL APPLICATIONS AND CELL DISRUPTION

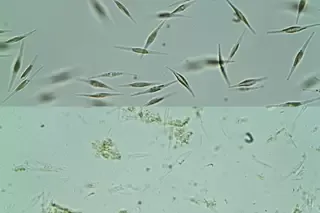

Mixer mills are frequently used for homogenizing biological samples. The so-called bead beating with small glass beads is an established method for cell disruption of yeasts, microalgae or bacteria. The sample is only moderately warmed in the process which can be reduced to a minimum by pre-cooling.

SOLUTIONS FOR CRYOGENIC GRINDING

APPLICATIONS IN MECHANOCHEMISTRY

- Process times of up to 99 h

- Various grinding jar sizes and materials

- Transparent PMMA grinding jars enable in-situ RAMAN spectroscopy

- Programmable frequency and break times

- Adapter for 4 x 5 ml stainless-steel grinding jars permits up to 8 simultaneous reactions

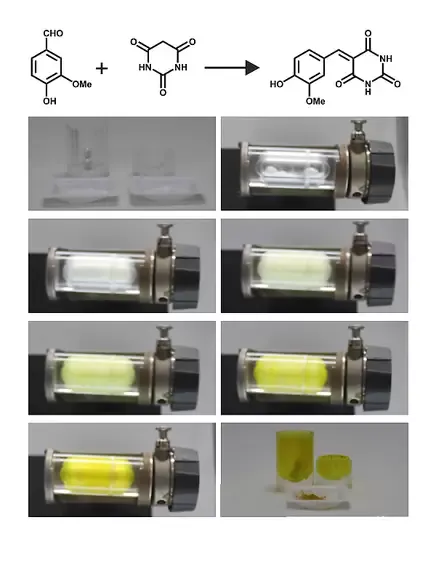

Time course of the Knoevenagel reaction between vanillin and barbituric acid under mechanochemical conditions using 2x10mm zirconium oxide grinding balls in 19 ml PMMA grinding jar at 30 Hz. Reaction running over 30 minutes with visible progress indicated by color change.

TYPICAL SAMPLE MATERIALS

FIBROUS: HAIR

30 ml sample

50 ml stainless steel jar 1 x 25 mm stainless steel ball 2 min at 30 Hz | CELL DISRUPTION: MICROALGAE

30 ml cell suspension 8 x 50 ml conical centrifuge tubes (adapter) with 25 ml glass beads each; 0,5-0,75 mm 30 s at 30 Hz |

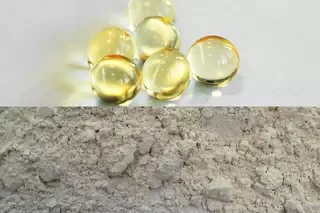

ELASTIC-LIQUID: CAPSULES WITH LIQUID 15 ml sample 50 ml stainless steel jar 1 x 25 mm stainless steel ball embrittlement in LN2 for 3 min 4 x 2 min at 30 Hz with intermediate cooling | MEDIUM-HARD/ FIBROUS: SOIL 20 ml sample

50 ml stainless steel jar 1 x 25 mm stainless steel ball 1 min at 30 Hz |

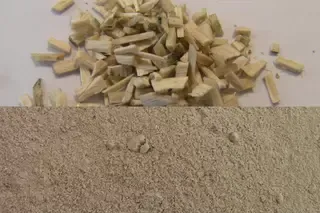

TOUGH-FIBROUS: WOOD 5 ml sample

10 ml zirconium oxide jar 2 x 12 mm zirconium oxide balls 3 min at 30 Hz | ELASTIC-TOUGH: POLYURETHANE PELLETS 20 ml sample 50 ml stainless steel jar 1 x 25 mm stainless steel ball embrittlement in LN2 for 3 min 4 x 2 min at 30 Hz with intermediate cooling |

FIBROUS: CANNABIS 3 g sample 50 ml stainless steel jar 1 x 25 mm stainless steel ball embrittlement with LN2 for 2 min 90 s at 30 Hz | HARD-BRITTLE: CONCRETE 10 ml sample

25 ml zirconium oxide jar 2 x 15 mm zirconium oxide balls 2 min at 30 Hz |

TECHNICAL DATA

| Applications | size reduction, mixing, homogenization, cell disruption, cryogenic grinding, mechanochemistry |

| Field of application | agriculture, biology, chemistry / plastics, construction materials, engineering / electronics, environment / recycling, food, geology / metallurgy, glass / ceramics, medicine / pharmaceuticals |

| Feed material | hard, medium-hard, soft, brittle, elastic, fibrous |

| Size reduction principle | impact, friction |

| Material feed size* | <= 8 mm |

| Final fineness* | ~ 5 µm |

| Batch size / feed quantity* | max. 2 x 20 ml |

| No. of grinding stations | 2 |

| Vibrational frequency | 3 - 30 Hz (180 - 1800 min-1) |

| Typical mean grinding time | 30 s - 2 min |

| Max. grindig time | 99 h |

| Dry grinding | yes |

| Wet grinding | yes |

| Cryogenic grinding | yes |

| Cell disruption with reaction vials | yes, up to 20 x 2.0 ml |

| Self-centering clamping device | yes |

| Type of grinding jars | screw top design |

| Material of grinding tools | hardened steel, stainless steel, tungsten carbide, agate, zirconium oxide, PTFE, PMMA |

| Grinding jar sizes | 1.5 ml / 5 ml / 10 ml / 25 ml / 35 ml / 50ml |

| Setting of grinding time | digital, 10 s - 8 h |

| Storable SOPs | 12 |

| Storable cycle programs | 6 |

| Electrical supply data | 100-240 V, 50/60 Hz |

| Power connection | 1-phase |

| Protection code | IP 30 |

| Power consumption | 165W |

| W x H x D closed | 385 x 350 x 470 mm |

| Net weight | ~ 27,5 kg |

| Standards | СЕ |

FUNCTIONAL PRINCIPLE

The grinding jars of the mixer mill MM 400 perform radial oscillations in a horizontal position. The inertia of the grinding balls causes them to impact with high energy on the sample material at the rounded ends of the jars and pulverize it. Also, the movement of the jars combined with the movement of the balls result in the intensive mixing of the sample.

The degree of mixing can be increased even further by using several smaller balls. If several small balls are used (e.g. glass beads) then, for example, biological cells can be disrupted. The large frictional impact effects between the beads ensure effective cell disruption.