MM 500 nano Mixer mill for ultra-precise laboratory grinding

The mixer mill MM 500 nano is a compact, versatile bench-top unit which has been developed specially for dry, wet and cryogenic grinding of up to 2 x 45 ml sample material within seconds. With a maximum frequency of 35 Hz, it generates enough energy to produce particles in the nanometer range.

HIGH SPEED BALL MILLING WITH EASY OPERATION FOR BEST RESULTS

- Max. speed 35 Hz

- Horizontal oscillation causes strong impact effects for effective sample processing

- Up to 10 mm feed size and 0.1 µm final fineness

- 2 grinding stations for jars of min. 2 ml and max. 125 ml, adapter for 18 x 2 ml single use vials

- Steel jars can be precooled manually in liquid nitrogen

- GrindControl to measure temperature and pressure inside the jar.

- Aeriation lids to control the atmosphere inside the jar

- Bench top model, touch screen, easy jar clamping, jars can stay clamped for subsampling, storable SOPs and cycle programs, 4 different jar materials for dry and wet grinding

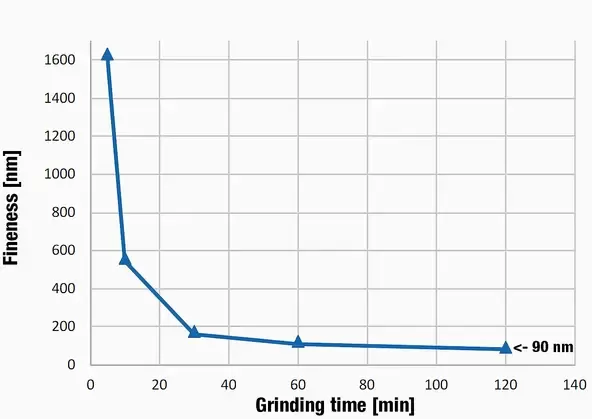

GRIND SIZES IN THE NANOMETER RANGE

- New jar design allows for optimized usage of jar volume also for wet grinding

- Final fineness < 100 nm possible thanks to maximized energy input at 35 Hz

- Less warming effects, thus grinding can usually be done without grinding breaks for cooling down

Result: You get your nano sample within the shortest time.

Nano grinding of 25 g titanium dioxide in a 125 ml grinding jar zirconium oxide with 275 g balls 0.1 mm, 30 ml 1% NaPO4 solution. A particle size of 90 nm was achievied after 120 minutes of grinding.

TYPICAL SAMPLE MATERIALS

RETSCH mixer mills are true allrounders. They homogenize, for example: alloys, animal feed, bones, ceramics, chemical products, coal, coke, drugs, electronic scrap, glass, grains, hair, minerals, oil seeds, ores, paper, plant materials, plastics, sewage sludge, soils, straw, tablets, textiles, tissue, tobacco, waste samples, wood, wool, etc.

titanium oxide

| metal alloy

| hair

| tyre rubber

|

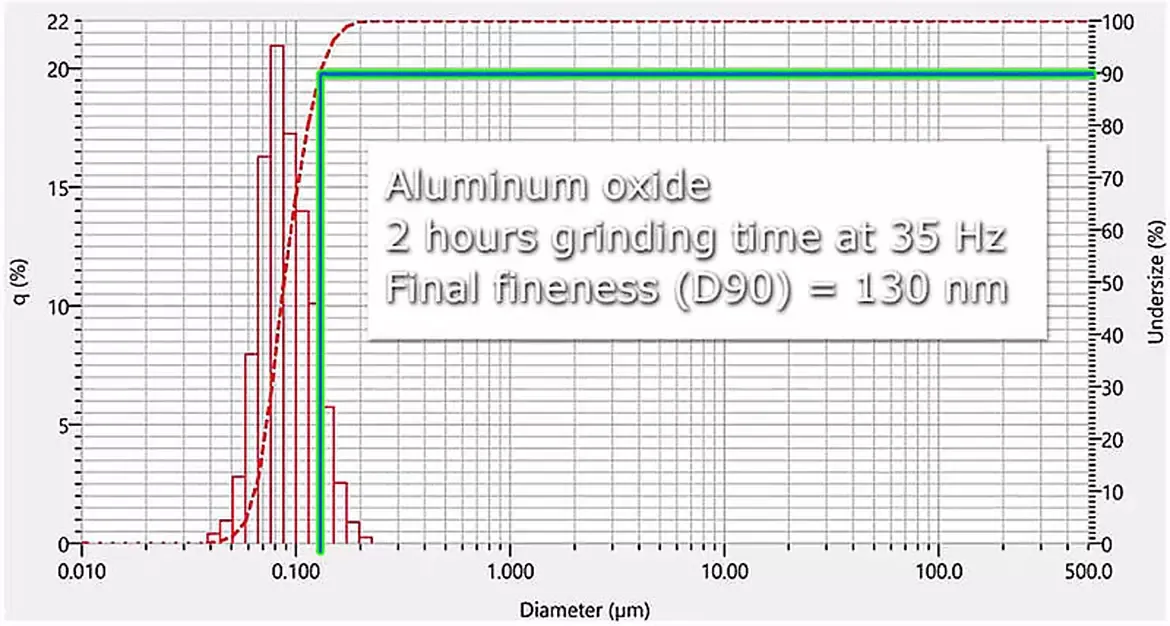

NANO GRINDING OF ALUMINUM OXIDE IN THE MM 500 NANO

Narrow particle size distribution of aluminium oxide after grinding (Nano grinding of 30 g aluminum oxide in a 125 ml grinding jar zirconium oxide with 275 g balls 0.1 mm, 33 ml 0.5% NaPO4 solution)

TECHNICAL DATA

| Applications | mechanochemistry, mechanical alloying, size reduction, mixing, homogenization, cryogenic grinding |

| Field of application | agriculture, biology, chemistry / plastics, construction materials, engineering / electronics, environment / recycling, food, geology / metallurgy, glass / ceramics, medicine / pharmaceuticals |

| Feed material | hard, medium-hard, soft, brittle, elastic, fibrous |

| Size reduction principle | impact, friction |

| Material feed size* | <= 10 mm |

| Final fineness* | ~ 0.1 µm |

| Batch size / feed quantity* | max. 2 x 45 ml |

| No. of grinding stations | 2 |

| Vibrational frequency | 3 - 35 Hz (180 - 2100 min-1) |

| Typical mean grinding time | 30 s - 2 min |

| Dry grinding | yes |

| Wet grinding | yes |

| Cryogenic grinding | yes |

| Cell disruption with reaction vials | no |

| Type of grinding jars | screw-lock jar with integrated safety closure devices, multi cavity jar, adapter for safe-lock reaction vials |

| Material of grinding tools | hardened steel, stainless steel, tungsten carbide, zirconium oxide |

| Grinding jar sizes | 10 ml / 25 ml / 50 ml / 80 ml / 125 ml |

| Setting of grinding time | digital, 10 s - 8 h |

| Total grinding time | 99 h |

| Storable SOPs | 12 |

| Number of storable cycle programs | 4 (with 99 repeats) |

| Electrical supply data | 100-120 V, 50/60 Hz; 200-230 V, 50/60Hz |

| Power connection | 1-phase |

| Protection code | IP 30 |

| Power consumption | 750 W |

| W x H x D closed | 690 x 375 x 585 mm |

| Net weight | ~ 60 kg |

| Standards | CE |