Vibrating mill MM 500 Vario for universal laboratory grinding applications

The new Mixer Mill MM 500 vario is a versatile bench-top unit which provides ultimate performance with maximum flexibility for your sample preparation process.

THE STRONG MIXER MILL FOR HIGH THROUGHPUT APPLICATIONS

- Max. speed 35 Hz

- Horizontal oscillation causes strong impact effects for effective sample processing

- Up to 8 mm feed size and 5 µm final fineness

- 6 grinding stations for jars of min. 2 ml and max. 50 ml, adapter holds up to 50 x 2 ml single use vials

- Steel jars can be precooled manually in liquid nitrogen

- Bench-top model, touch screen, storable SOPs and cycle programs, 7 different jar materials

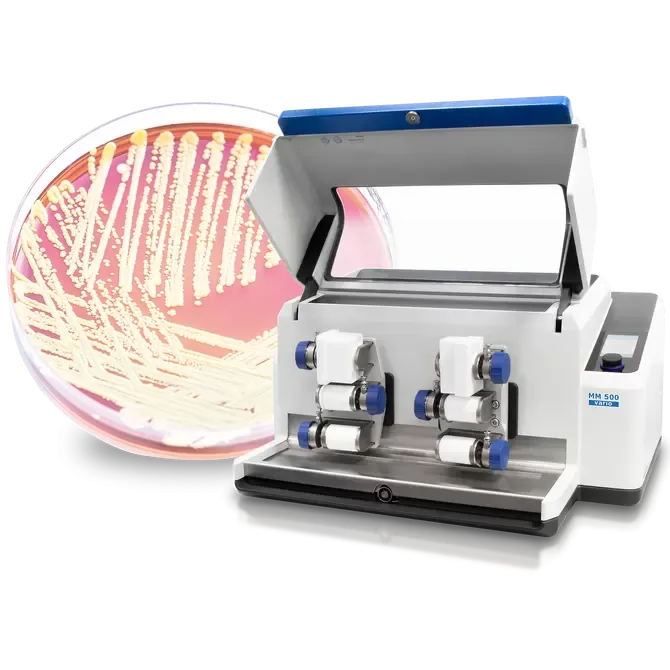

SOLUTIONS FOR BIOLOGICAL APPLICATIONS AND CELL DISRUPTION

MAXIMIZE YOUR THROUGHPUT

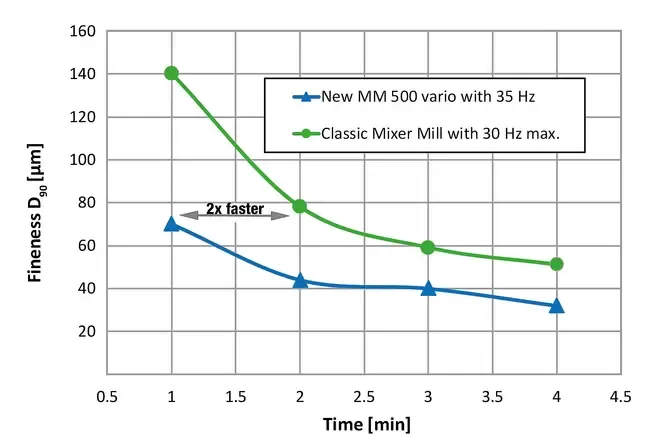

- Maximum frequency of 35 Hz reduces grinding time to 50% compared to mixer mills with only 30 Hz

- Six grinding stations instead of two, as in classic mixer mills, ensure high throughput

- In combination, the throughput of the MM 500 vario is 6 times higher compared to a classic mixer mill

Grinding of basalt in the MM 500 vario results in better fineness compared to classic Mixer Mills thanks to the increased frequency of 35 Hz instead of 30 Hz (50 ml jar + 12 x 12 mm grinding balls).

Grinding of basalt in the MM 500 vario results in better fineness compared to classic Mixer Mills thanks to the increased frequency of 35 Hz instead of 30 Hz (50 ml jar + 12 x 12 mm grinding balls).

TYPICAL SAMPLE MATERIALS

RETSCH mixer mills are true allrounders. They homogenize, for example, waste, soil, chemical products, coated tablets, drugs, ores, grain, tissue, glass, hair, ceramics, bones, plastics, alloys, minerals, oil seeds, plants, sewage sludge, pills, textiles, wool etc.

concrete

| wood

| plastic granulates

| hair

|

TECHNICAL DATA

| Applications | mechanochemistry, homogenization, size reduction, cryogenic grinding, mechanical alloying, mixing, |

| Field of application | agriculture, biology, chemistry / plastics, construction materials, engineering / electronics, environment / recycling, food, geology / metallurgy, glass / ceramics, medicine / pharmaceuticals |

| Feed material | hard, medium-hard, soft, brittle, elastic, fibrous |

| Size reduction principle | impact, friction |

| Material feed size* | <= 8 mm |

| Final fineness* | ~ 5 µm |

| Batch size / feed quantity* | max. 6 x 20 ml |

| No. of grinding stations | 6 |

| Vibrational frequency | 3 - 35 Hz (180 - 2100 min-1) |

| Typical mean grinding time | 30 s - 2 min |

| Dry grinding | yes |

| Wet grinding | yes |

| Cryogenic grinding | yes |

| Cell disruption with reaction vials | yes |

| Self-centering clamping device | yes |

| Type of grinding jars | screw top design |

| Material of grinding tools | hardened steel, stainless steel, tungsten carbide, zirconium oxide, agate, PTFE |

| Grinding jar sizes | 1.5 ml / 5 ml / 10 ml / 25 ml / 35 ml / 50 ml |

| Setting of grinding time | digital, 10 s - 8 h |

| Total grinding time | 99 h |

| Storable SOPs | 12 |

| Number of storable cycle programs | 4 (with 99 repeats) |

| Electrical supply data | 100-120 V, 50/60 Hz; 200-230 V, 50/60Hz |

| Power connection | 1-phase |

| Protection code | IP 30 |

| Power consumption | 750 W |

| W x H x D closed | 690 x 375 x 585 mm |

| Net weight | ~ 60 kg |

| Standards | CE |