High temperature industrial chamber furnace HTF up to 1800 °C

APPLICATION EXAMPLES

STANDARD FEATURES

- 1600 °C, 1700 °C & 1800 °C maximum operating temperatures

- From 27 to 560 litre capacities

- Programmable EPC3016P1 controller

- Over-temperature protection

- High quality molybdenum disilicide heating elements

- Advanced refractory interior, used in combination with energy efficient low thermal mass insulation

- Automatic movement of the door

- Controller mounted on a user-friendly satellite

- Ethernet communications

OPTIONS (SPECIFY THESE AT TIME OF ORDER)

- A range of sophisticated digital controllers, multisegment programmers and data loggers with digital communication options is available - more information about controllers

- Fast cooling option to reduce the natural cool down time below 600 °C

- Current voltage display

- Debinding options on request

- Gas supply with manually adjustable flow meter

- Modification of the atmosphere in the furnace chamber can be achieved but oxygen cannot be removed completely because it is not gas tight

TECHNICAL DETAILS

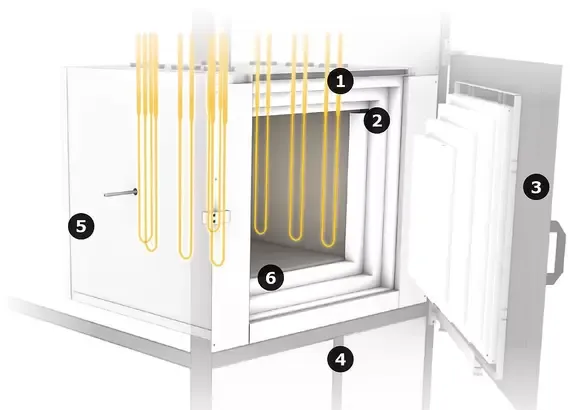

View inside the 1700 °C and 1800 °C HTF chamber furnace:

- heating elements (MoSi2)

- ceramic fibre insulation

- front door

- supporting frame

- thermocouple

- usable space

MoSi2, U-shaped heating elements are mounted in a vertical, hanging position in the HTF. Heat is insulated with ceramic fibre plates which are constructed in layers with a suited thickness for improved temperature uniformity. The maximum temperature of the plates is selected depending on the maximum temperature of the furnace.

Water cooling is not required as the insulation material has low heat conductance. The system is externally cooled by convection of ambient air and encased by the metallic plates. The MoSi2 heating elements are especially suited for high temperature processes. At high temperatures, the MoSi2 naturally creates a protective oxide layer. Outstanding temperature uniformity and compact design are unique features of the HTF chamber furnace.

EXAMPLES

HTF 17/64 with debinding option incl. active propane afterburner and Mini8 touchscreen controller

HTF 17/64 with Mini8 touchscreen controller