RS 200 Disk Mill Retsch

No grinder can beat the speed of a Vibratory Disc Mill when it comes to preparing samples for spectral analyses. RETSCH’s Vibratory Disc Mill RS 200 is ideally suited for fast and reproducible pulverization of hard, brittle and fibrous sample materials to analytical fineness.

FAST & REPRODUCIBLE

- Very short grinding times, typically in the range of 60 to 180 seconds to achieve a fineness around 100 μm

- Ergonomic design and carry handles ensure easy handling of the grinding set

- Quick-action clamping system enables convenient and safe tightening of the grinding set

- Automatic speed reduction for agate and tungsten carbide sets

- Powerful Stabilized-Plane-Drive improves reproducibility

- Variable speed from 700 to 1500 rpm

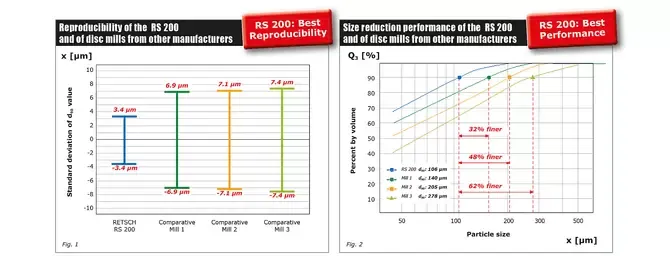

PERFORMANCE TEST: SIZE REDUCTION AND REPRODUCIBILITY

The grinding results of a vibratory disc mill are significantly influenced by the movement patterns of the free masses inside the grinding jar. The new, powerful Stabilized-Plane-Drive of the RS 200 allows for extremely rapid formation of the movement pattern which is reflected in higher fineness and ultimately leads to significantly better reproducibility.

- Grinding jar: 100 ml

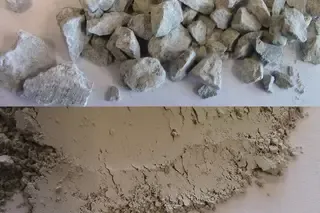

- Sample: cement clinker 0.85 to 3.15 mm

- Speed: Maximum (1200 rpm)

- Grinding time: 60 sec (Figure 1), 15 sec (Figure 2)

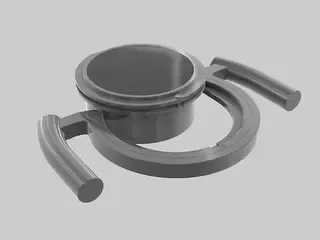

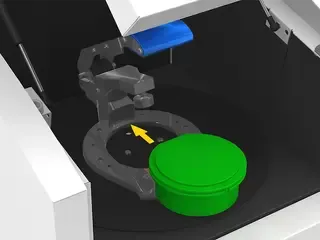

EXCEPTIONALLY SAFE AND SIMPLE HANDLING

Operation and handling of the RS 200 and its grinding sets is convenient and ergonomic. The grinding jars are equipped with carry handles which facilitate transport of the heavy jar to the mill where it is slid on a rail into its grinding station. The clamping device allows for safe fastening of the jar with less force; a sensor checks its correct position.

- safe, non-slip attachment with integral safety devices on cover and base

- gap between dish and cover edge for easy opening

- optimum sealing with O-ring

- protective jacket made from stainless steel (for agate, zirconium oxide and tungsten carbide dishes)

- grinding set identification (article number, material and volume)

- marking field (e. g. for information about sample)

- available in 3 sizes and 5 materials

POWERFUL TWIN PACK FOR XRF ANALYSIS

To ensure accurate and reproducible XRF analysis results, the sample needs to have a uniform particle size distribution and the pellet to be pressed needs to be as dense as possible. Both requirements are easily met when using our vibratory disc mills and pellet presses for sample preparation to XRF analysis.

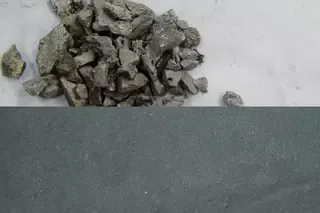

TYPICAL SAMPLE MATERIALS

RETSCH’s Vibratory Disc Mills rapidly pulverize materials such as cement, cement clinker, ceramics, coal, coke, concrete, corundum, glass, metal oxides, minerals, ores, silicate, slag, soil, etc.

TECHNICAL DATA

| Applications | size reduction, mixing, triturating |

| Field of application | construction materials, environment / recycling, geology / metallurgy, glass / ceramics |

| Feed material | medium-hard, hard, brittle, fibrous |

| Size reduction principle | pressure, friction |

| Material feed size* | < 15 mm |

| Final fineness* | < 20 µm |

| Batch size / feed quantity* | 15- 250 ml depending on size of grinding set |

| Speed at 50 Hz (60 Hz) | 700 - 1,500 min-1, continuously adjustable |

| Material of grinding tools | hardened steel, tungsten carbide, agate, zirconium oxide, steel 1.1740 (for heavy-metal free grinding) |

| Grinding jar sizes | 50 ml / 100 ml / 250 ml |

| Setting of grinding time | digital, 00:01 to 99:59 |

| Storable SOPs | 10 |

| Drive | 3-phase asynchronous motor with frequency converter |

| Drive power | 1.5 kW |

| Electrical supply data | different voltages |

| Power connection | 1-phase |

| Protection code | IP 20 |

| W x H x D closed | 836 x 1220 x 780 mm |

| Net weight | ~ 225 kg (without grinding set) |

| Standards | СЕ |