Heating Microscope EM301

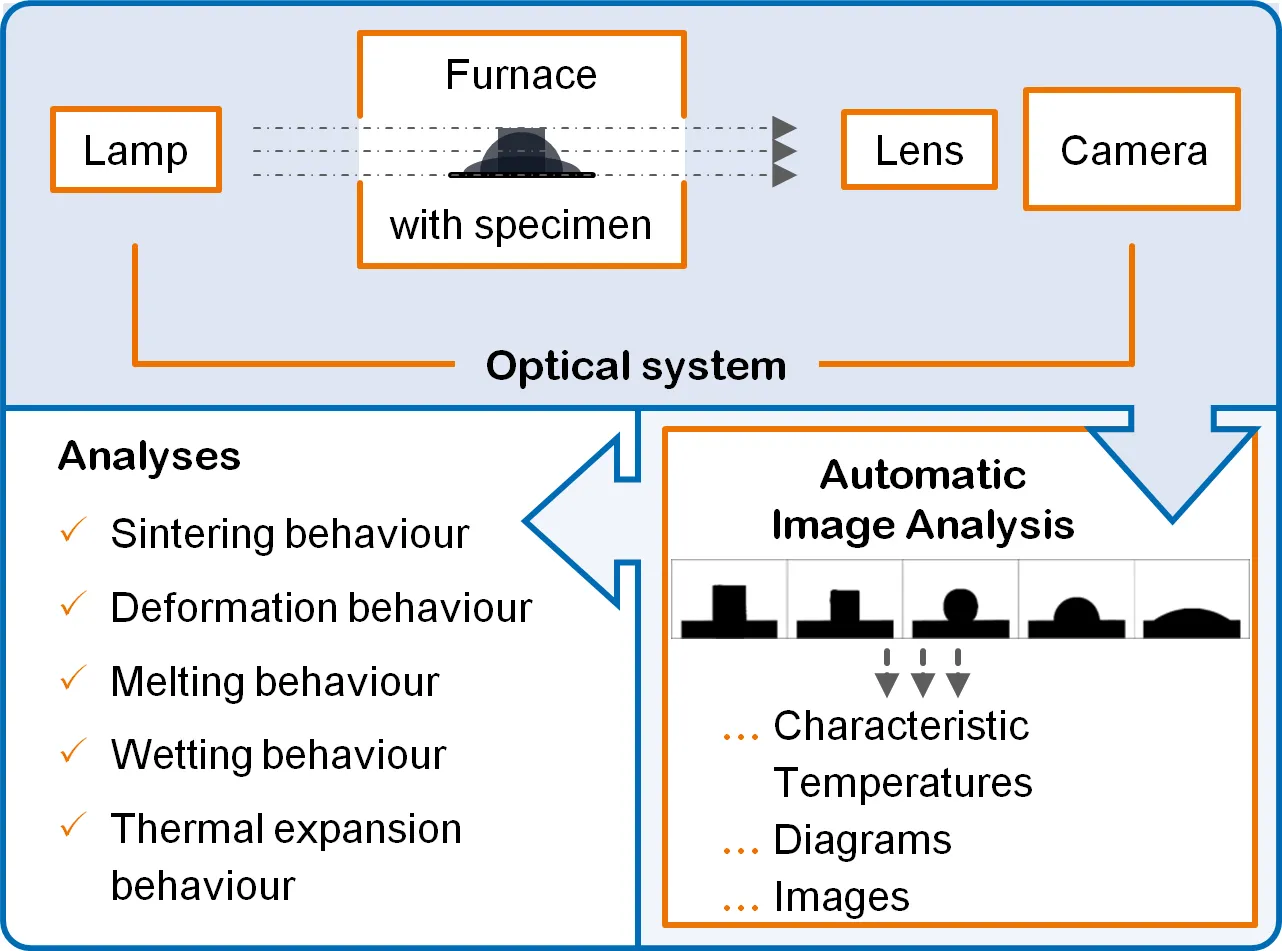

Operating principle and analyses

- sintering characteristics

- softening characteristics

- melting characteristics

- thermal expansion characteristics

- wetting characteristics

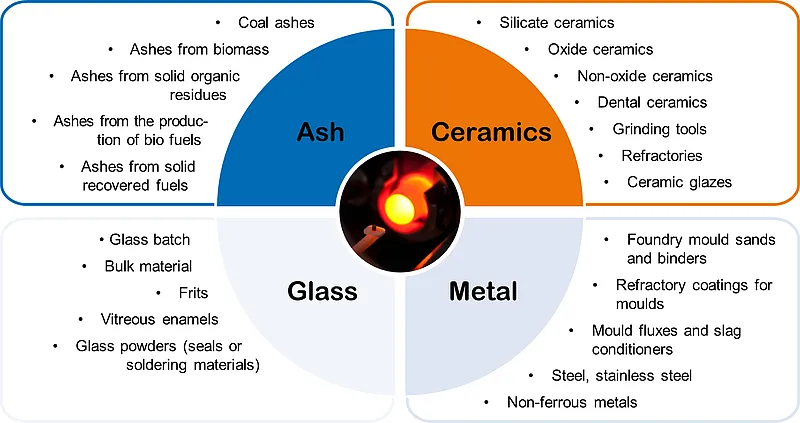

Fields of use and applications

The EM301 is used in research, development and quality control – not only in industry but also in institutes and universities. As well as for analysing the melting characteristics of ashes, the heating microscope has applications in the glass, ceramic and metalworking industries. The following standards for analysing the melting characteristics of ashes are implemented in the EM301:

- DIN 51730:2007

- DIN EN ISO 21404:2020

- ISO 540:2008-06

- CEN/TS 15370-1:2006 und CEN/TR 15404:2006

- the Hesse Instruments method, which is based on DIN 51730:1984

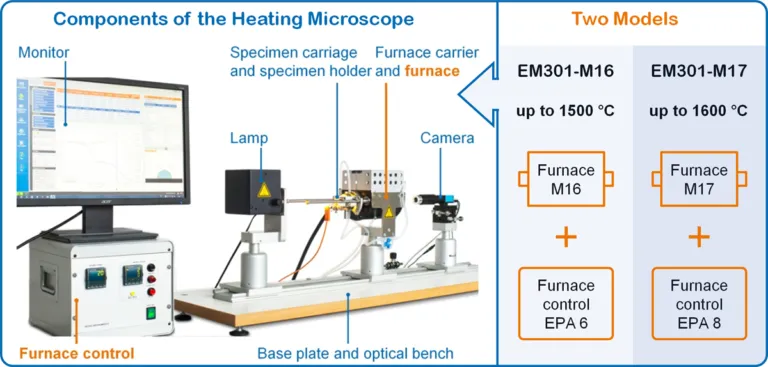

Modular construction and components

The EM301 is available in various models with different maximum temperatures and heating rates. The overall construction of the EM301 is based on a modular principle in which the individual components are mounted in separate housings. This simplifies adaptation to individual requirements and minimises the influence of vibrations, allowing precise, reliable analyses.

- Optical bench with lamp, stands and camera

- Furnace system with furnace control unit, furnace and transformer

- EMI III heating microscope software on preconfigured measuring station computer with accessories

- Optional: Recirculating cooler and other accessories

Method

Non-contact measurement of the test piece

- Various analytical capabilities

- Wide range of applications

- Determination of sintering, softening, melting, thermal expansion, and wetting characteristics

Implementation of various measurement methods

- Several methods for the determination of characteristic temperatures

- Hesse Instruments method, suitable for analysing a wide range of materials

- Method for analysing the melting characteristics of ashes in accordance with standards

Construction and components

Open and modular design

- Easy adaptation to individual requirements/real-life process conditions

- Implementation of alternative measurement concepts

- Easy access to components

Sturdy construction and high-quality components

- High precision and accuracy

- Durability and low susceptibility to faults

- Long-term reliability of results

Design of measuring cell

- Heating of test pieces to temperatures above the melting point

- Analyses at temperatures of up to 1600°C

- Adjustment of furnace atmosphere

- Protection of specimen thermocouple and heating element against contamination

Sophisticated furnace system

- Improved safety and protection of the furnace during operation

Automation

Software-based operation and automatic image analysis

- Easy manipulation

- Time savings and standardisation

Automatic image analysis

- Accurate and precise measurement results

- Reduction of systematic errors