Planetary Ball Mill RM 100 Retsch – Precise Laboratory Grinding

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easy-to-use counterweight which compensates masses up to 8 kg. It allows for grinding up to 220 ml sample material per batch.

THE IDEAL BALL MILL FOR STANDARD APPLICATIONS

- Max. speed 650 rpm

- Up to 10 mm feed size and 0.1 µm final fineness

- 1 grinding station for jars from 12 ml up to 500 ml

- Jars of 12 – 80 ml can be stacked (two jars each)

- GrindControl to measure temperature and pressure inside the jar.

- Aeriation lids to control the atmosphere inside the jar

- Storable SOPs and cycle programs, 5 different jar materials for dry and wet grinding

FAST & POWERFUL

- Loss-free size reduction down to the submicron range

- Wet grinding yields particle sizes in the nanometer range (<100 nm)

- Variable speed from 100 to 650 rpm,

- speed ratio 1:-2

- Grinding with up to 33.3 x acceleration of gravity

- Batch-wise processing with max. 1 x 220 ml sample

- 2 x 20 ml sample per batch with stacked jars

REPRODUCIBILITY, SAFETY AND EASY HANDLING

- Reproducible results due to speed control

- Easy and safe clamping of grinding jars

- The Safety Slider prevents starting the machine without securely clamped jars

- Perfect stability on the lab bench thanks to FFCS technology

- Innovative counterweight and imbalance sensor for unsupervised operation

- Comfortable parameter setting via display and ergonomic 1-button operation

- Automatic grinding chamber ventilation

- 10 SOPs can be stored, programmable starting time

- Power failure backup ensures storage of remaining processing time

SETTINGS & OPTIONS

- Dry and wet grinding possible

- Suitable for long-term trials, 99 h max.

- Interval operation allows for cooling breaks

- Direction reversal helps to minimize caking effects

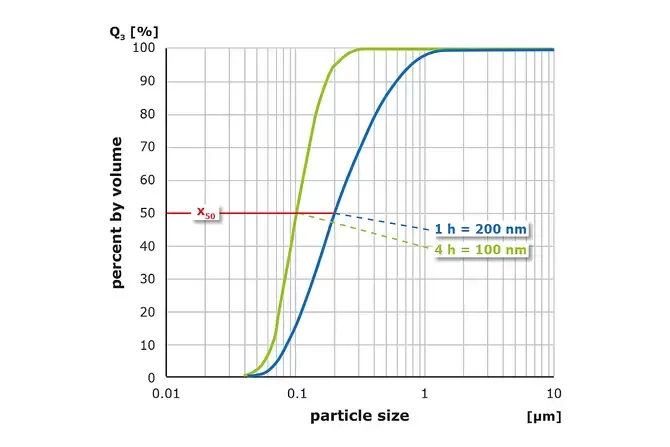

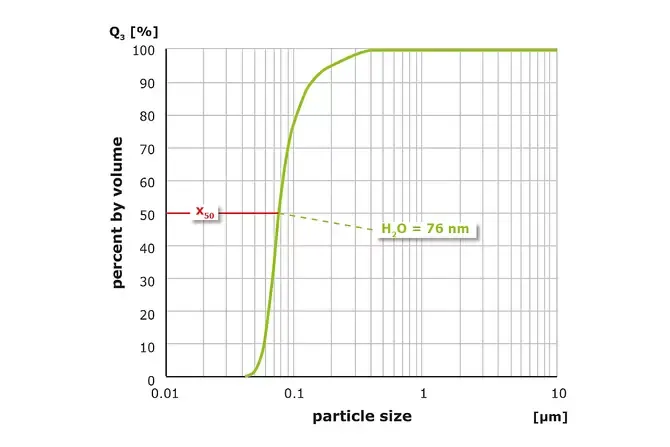

WET AND NANO-SCALE GRINDING WITH THE PM 100

Wet grinding is used to obtain particle sizes below 5 µm, as small particles tend to get charged on their surfaces and agglomerate, which makes further grinding in dry mode difficult. By adding a liquid or dispersant the particles can be kept separated.

The graphic shows the result of grinding alumina (Al2O3) at 650 rpm in the PM 100. After 1 h of size reduction in water with 1 mm grinding balls, the mean value of the particle size distribution is 200 nm; after 4 h it is 100 nm.м | In another trial, the material was first pulverized for 1 hour with 1 mm grinding balls and then for 3 hours with 0.1 mm grinding balls. In this case, an average size of 76 nm was achieved. |

TYPICAL SAMPLE MATERIALS

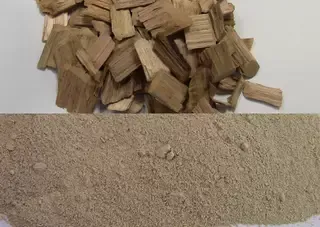

| TOUGH-FIBROUS: WOOD

40 g sample 500 ml stainless steel grinding jar 8 x 30 mm stainless steel grinding balls 5 min at 380 rpm | HARD-BRITTLE: MAGNETITE

315 g sample 250 ml tungsten carbide grinding jar 15 x 20 mm tungsten carbide grinding balls 5 min at 500 rpm | MEDIUM-HARD: SOIL

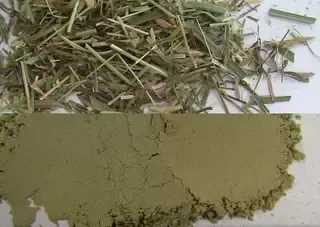

45 ml sample 125 ml stainless steel grinding jar 7 x 20 mm stainless steel grinding balls 2 min at 400 rpm | FIBROUS: DRIED GRASS

|

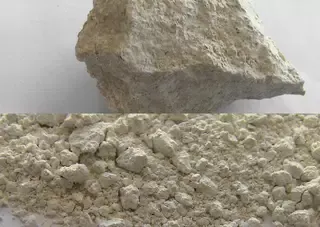

| MEDIUM-HARD/ FIBROUS: SEWAGE SLUDGE 20 g sample 125 ml zirconium oxide grinding jar 50 x 10 mm zirconium oxide grinding balls 30 min at 380 rpm with direction reversal | MEDIUM-HARD: LIMESTONE 170 ml sample 500 ml zirconium oxide grinding jar 8 x 30 mm zirconium oxide grinding balls 3 min at 450 rpm | HARD-BRITTLE: LAPIS LAZULI

4 sample pieces 50 ml zirconium oxide grinding jar 3 x 20 mm zirconium oxide grinding balls 2 min at 420 rpm | SOFT - WET GRINDING: CAROTENE

|

TECHNICAL DATA

| Applications | pulverizing, mixing, homogenizing, colloidal milling, mechanical alloying, mechanosynthesis, nano grinding |

| Field of application | agriculture, biology, chemistry, construction materials, engineering / electronics, environment / recycling, geology / metallurgy, glass / ceramics, medicine / pharmaceuticals |

| Feed material | soft, hard, brittle, fibrous - dry or wet |

| Size reduction principle | impact, friction |

| Material feed size* | < 10 mm |

| Final fineness* | < 1 µm, for colloidal grinding < 0.1 µm |

| Batch size / feed quantity* | max. 1 x 220 ml, max. 2 x 20 ml with stacked grinding jars |

| No. of grinding stations | 1 |

| Speed ratio | 1 : -2 |

| Sun wheel speed | 100 - 650 min-1 |

| Effective sun wheel diameter | 141 mm |

| G-force | 33.3 g |

| Type of grinding jars | EasyFit, optional areation covers, safety closure devices |

| Material of grinding tools | hardened steel, stainless steel, tungsten carbide, agate, sintered aluminum oxide, silicon nitride, zirconium oxide |

| Grinding jar sizes | 12 ml / 25 ml / 50 ml / 80 ml / 125 ml / 250 ml / 500 ml |

| Stackable grinding jars | 12 ml / 25 ml / 50 ml / 80 ml |

| Setting of grinding time | digital, 00:00:01 to 99:59:59 |

| Interval operation | yes, with direction reversal |

| Interval time | 00:00:01 to 99:59:59 |

| Pause time | 00:00:01 to 99:59:59 |

| Storable SOPs | 10 |

| Interface | RS 232 / RS 485 |

| Drive | 3-phase asynchronous motor with frequency converter |

| Drive power | 750 W |

| Electrical supply data | different voltages |

| Power connection | 1-phase |

| Protection code | IP 30 |

| Power consumption | ~ 1250W (VA) |

| W x H x D closed | 640 x 480 (780) x 420 mm |

| Net weight | ~ 86 kg |

| Standards | CE |

| Patent / Utility patent | Counter weight (DE 20307741), FFCS (DE 20310654), SafetySlider (DE 202008008473) |