Precision cut-off machine QCUT 150 A

PRODUCT ADVANTAGES

- Up to 5 different modes: manual, automatic feed, force-controlled feed, grinding mode, cutting with table attachment (depending on machine configuration)

- Manual cross feed

- Zone cutting function

- 4 different cooling systems availabe

- Dressing device

- Intuitive QATM software with integrated database

FEATURES

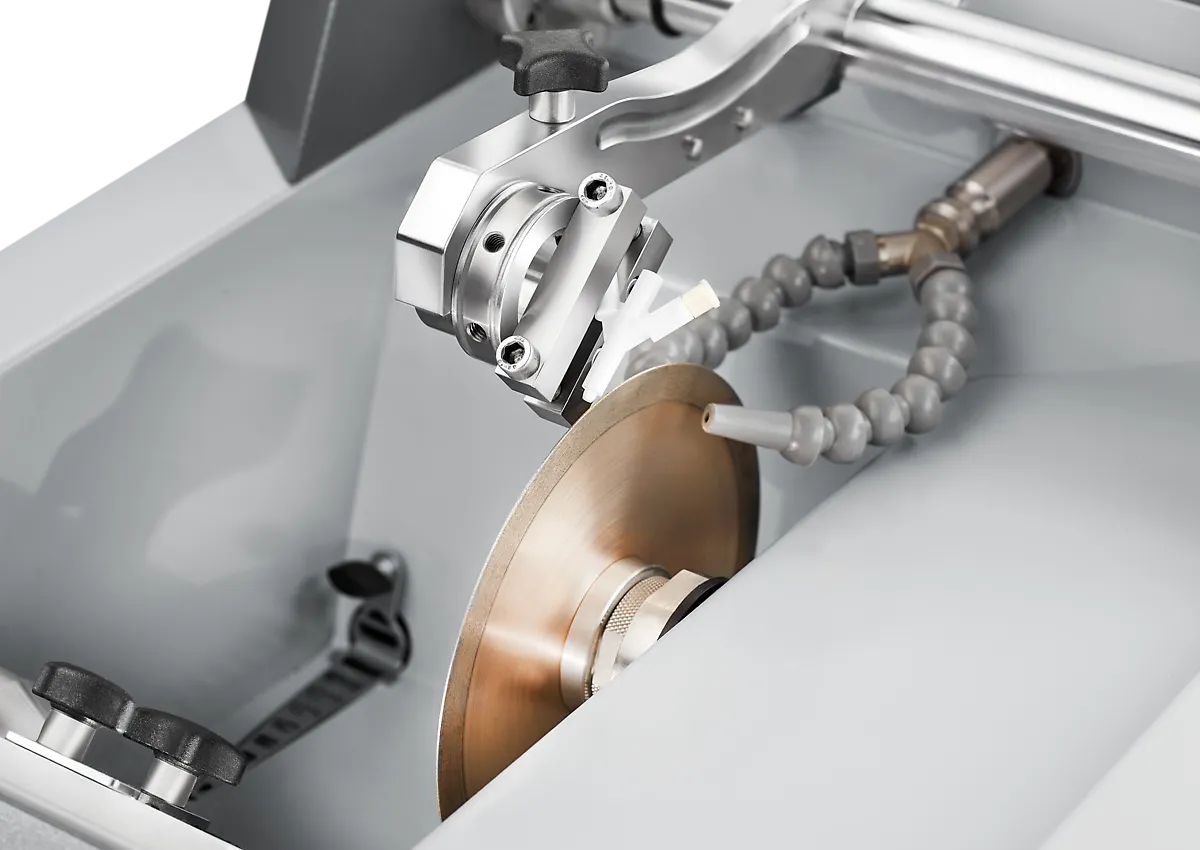

FORCE-CONTROLLED CUTTING

The cutting force gets precisely controlled by an integrated force-sensor. It keeps the cutting force constant by adjusting the feed rate automatically throughout the cutting process.

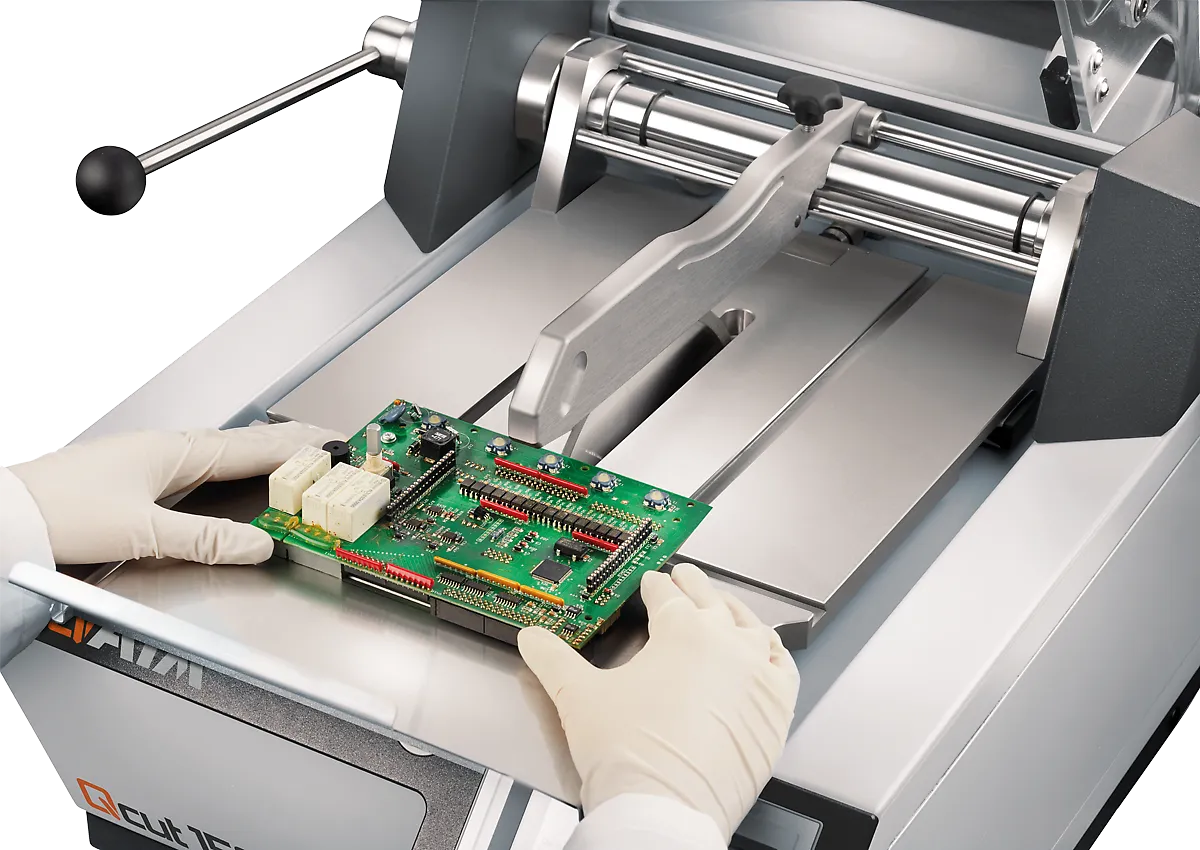

TABLE ATTACHMENT

With the tool-free mountable table attachment PCBs, plate material or large samples can be quickly sectioned manually.

CUTTING

The new functionality “zone cutting” allows for setting feed rate or cutting force individually for single sections of the specimen for one cutting operation. Material deformation and warming are thus reduced, making the cutting process more effective.

REDUCES SUBSEQUENT GRINDING PROCESSES

The use of the adaptive rotation axis leads to an even more uniform cutting pattern and reduces the risk of the cut-off wheel running. This reduces the effort required for later plane-parallel grinding of the sample.

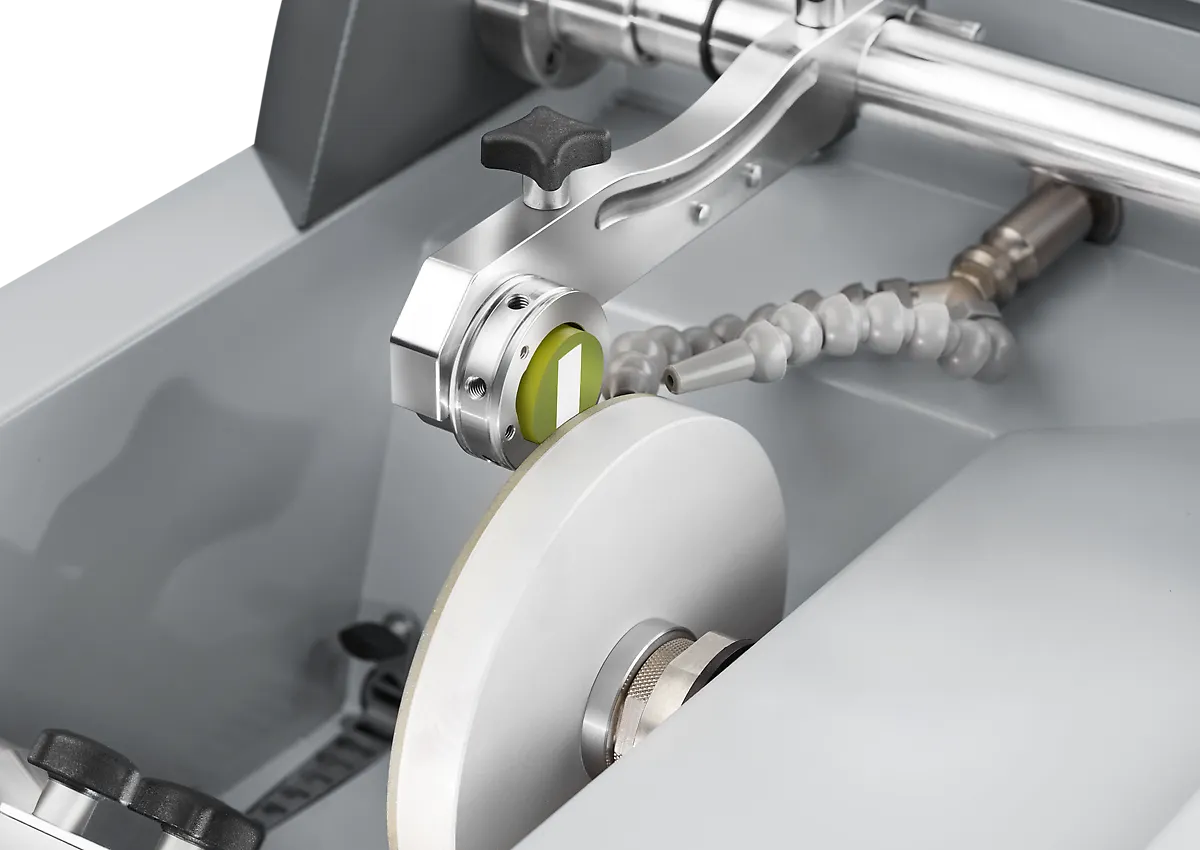

GRINDING MODE

In grinding mode, samples can be grinded down with a cup wheel manually or semi-automatically (Target preparation).

EXTENSIVE RANGE OF CLAMPING TOOLS

With the help of a suitable clamping tool from the extensive range of accessories, embedded or non-embedded samples up to a size of Ø 40 mm can be clamped in the cutting machine comfortably.

Larger samples such as PCBs and plate material can be quickly and manually cut with the table top that can be mounted without additional tools.