Cutting mill SM 200 - Laboratory equipment for grinding materials

Cutting mills are suitable for the grinding of soft, medium-hard, tough, elastic, fibrous, and heterogeneous mixes of products. Within the group of RETSCH cutting mills, the SM 200 is the universal standard model which covers a vast range of applications.

FOR UNIVERSAL APPLICATIONS

- Feed size <60 x 80 mm

- Defined final fineness due to bottom sieves with aperture sizes from 0.25 - 20 mm

- Optimum cutting effects thanks to double acting cutting bars

- Quick and easy cleaning due to smooth surfaces, fold back hopper, push-fit rotor and sieves

- Operation with gravity outlet or optionally available cyclone unit possible

- Wide range of accessories including various hoppers, collection systems, rotors and sieves

- Highest safety standards due to engine brake, central locking device, electronic safety check and safety base frame

EASY OPERATION & CLEANING

Operation of the SM 200 is exceptionally simple and safe. A safety switch prevents the mill from being switched on with the door open. An electronic safety check ensures that the door cannot be opened when the motor is running – the motor brake makes the rotor come to an immediate standstill after the mill has been switched off.

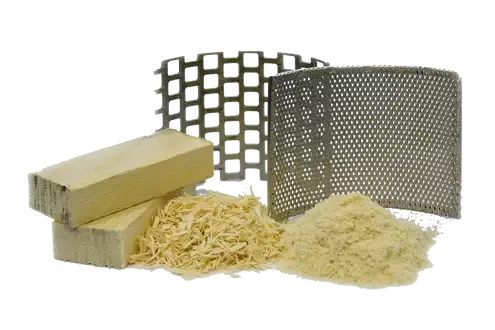

TYPICAL SAMPLE MATERIALS

TECHNICAL DATA

| Applications | size reduction by cutting |

| Field of application | agriculture, biology, chemistry / plastics, engineering / electronics, environment / recycling, food, medicine / pharmaceuticals |

| Feed material | soft, medium-hard, tough, elastic, fibrous |

| Size reduction principle | shearing, cutting |

| Material feed size* | < 60 x 80 mm |

| Final fineness* | 0.25 - 20 mm |

| Speed at 50 Hz (60 Hz) | 1,500 min-1 |

| Rotor peripheral speed | 9.4 - 11.4 m/s |

| Rotor diameter | 129.5 mm |

| Types of rotors | parallel section rotor / 6-disc rotor |

| Types of hoppers | standard, long stock |

| Material of grinding tools | stainless steel, steel for heavy-metal free grinding, tungsten carbide |

| Sieve sizes | trapezoid holes 0.25 / 0.50 / 0.75 / 1.00 / 1.50 mm

square holes 2.00 / 4.00 / 6.00 / 8.00 / 10.00 / 20.00 mm |

| Collector systems / capacities | collecting receptacle 5 l / optional: 30 l

collecting unit 0.25 / 0.5 l cyclone-suction combination (0.25 l - 30 l) |

| Drive | 3-phase motor |

| Drive power | 2.2 kW |

| Electrical supply data | different voltages |

| Power connection | 3-phase |

| Engine brake | yes |

| Protection code | IP54 |

| W x H x D closed | 576 (1090 opened) x 1675 x 760 mm (with base frame and standard hopper) |

| Net weight | ~ 90 kg without hopper |

| Standards | CE |