Rockwell hardness tester QNESS 150 CSA+

Артикул: QNESS 150 CSA+

SIMPLE AND EFFICIENT ROCKWELL HARDNESS TESTING

The Qness 150 CSA+ incorporates the best of all proven concepts and practices: the versatility of an automatic hardness tester and the speed of our Rockwell testers.

A fully automatic XY slide will guarantee high precision hardness testing. It is ideal for fully automatic series and progression tests on parts with identical test heights. However, individual tests can be performed, too.

Product Advantages

- Large test force range (1kg – 250kg)

- Automatic 3-axis control

- Short cycle times

- Identical sample tests

- Robust, welded steel frame

- Infinitely adjustable test table height

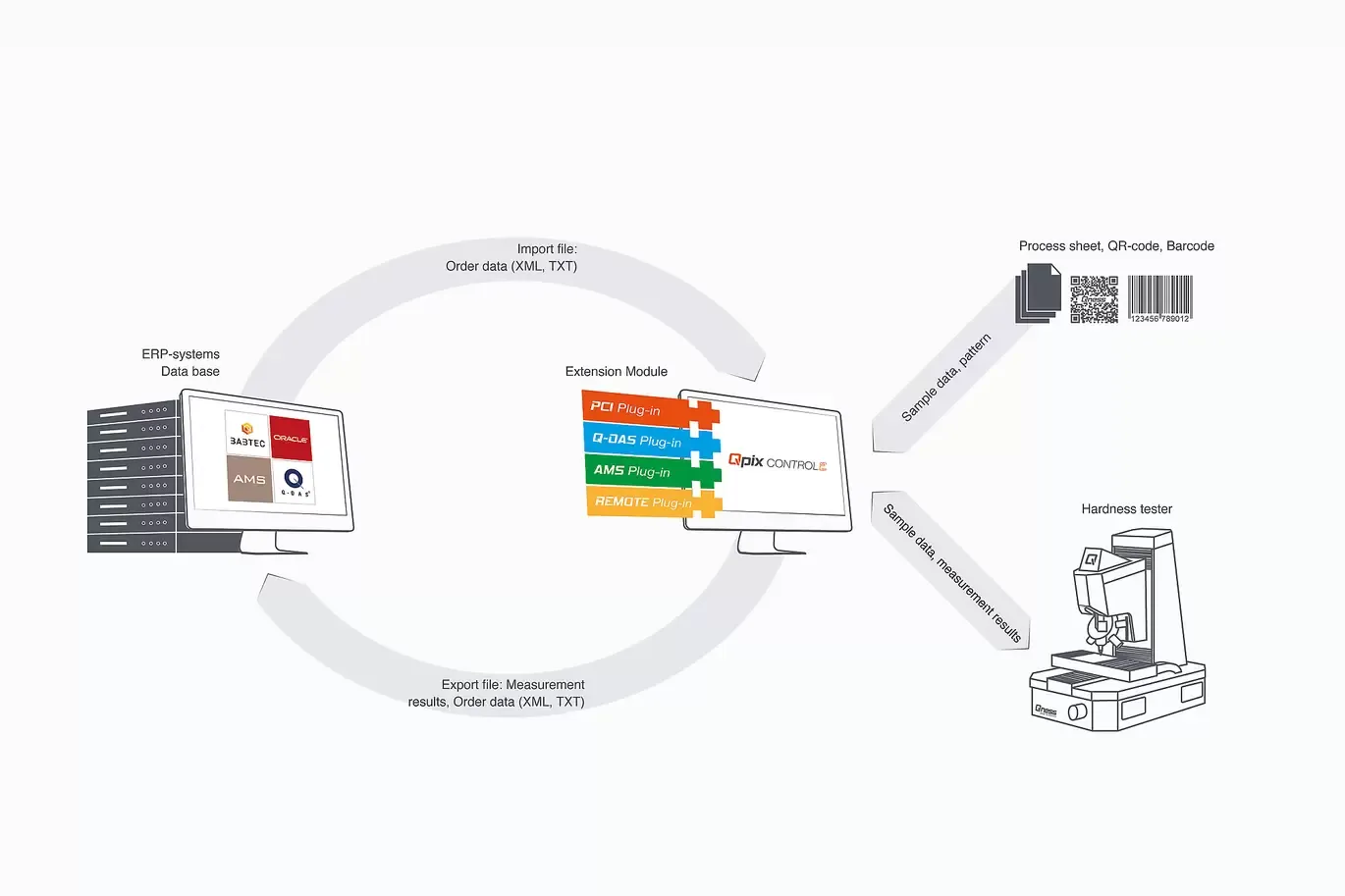

TEST METHODS & FORCE RANGE

Integrated conversions: DIN EN ISO 18265, DIN EN ISO 50150, ASTM E140

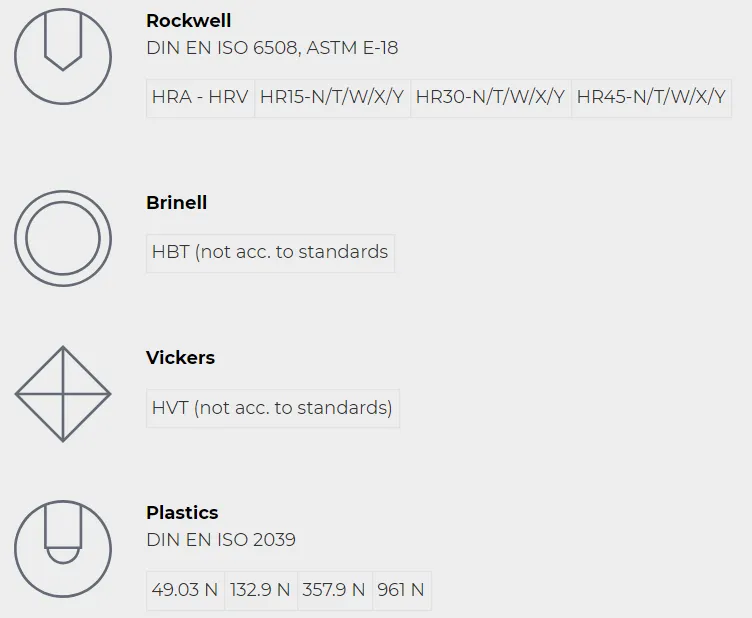

FULLY AUTOMATED TEST CYCLE

Electronic force application and closed-loop control

SOPHISTICATED CONSTRUCTION, ULTRA-SIMPLE OPERATION

COMPACT DESIGN - LATEST TECHNOLOGY

- Controlled force application (1kg to 250kg)

- Machine versions to serve all applications and test piece size

- Direct depth-gauge-system (0.05μm resolution)

- Robust welded steel frame and sheet steel covers

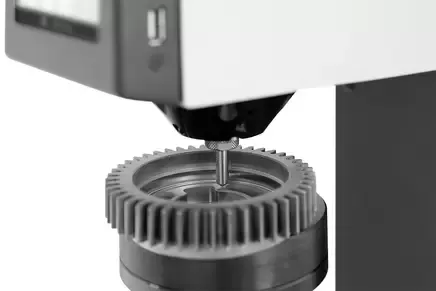

REMOVABLE DOWNHOLDER

No need for long retooling breaks due to inaccessible test points. The clamping head can be removed via 2 screws. Now, even test points in hard-to-reach contours can be accessed with ease.

QNESS 150 CS/CSA ECO PEDESTAL

No suitable table in the testing area? No problem! The Qness 150 CS/CSA ECO matches perfectly with the machine’s optional pedestal. The superior-quality subframe is color-matched to the hardness testing device. The machine pedestal includes a spacious, lockable compartment in which to store accessories. Beechwood (40 mm thick) with a spindle bore.

INTUITIVE FEATURES AND OPERATION

TEST TABLE HEIGHT ADJUSTMENT

The height of the test table is infinitely adjustable (position can be fixed) via the play-free roller-bearing spindle guide - ideal for fully automatic series and progression tests on parts with identical test height. The test sequence is performed without clamping. Individual tests can also be carried out with the patented, swivelling downholder clamp.

AUTOMATIC PROGRESSIONS

The automatic XY slide with high-precision positioning drive enables extensive test series and hardness curves. External joystick for controlling the axis. Usable support surface: 180 x 200 mm, Traverse path: X 220 / Y 220 mm.

FULLY AUTOMATED 3-AXIS CONTROL

Fully automatic and robust XY slide with high-precision positioning drive. Dynamic joystick to control all 3 axes (XYZ). Usable support surface 200 x 180 mm.

IDENTICAL SAMPLE TESTS

An entire range of relevant data, such as test patterns, test methods and user fields can be activated via pre-defined sample magazines. QATM can provide the most suitable clamping setup, matrices and cassette systems for every requirement.

SAMPLE IMAGE CAMERA

Ultimate ease of use with 5 megapixel colour camera for recording the entire sample for a perfect overview and documentation in the protocol. It is standard in the CSA+ versions to record the entire table surface as sample image.

MAXIMUM CLAMPING SAFETY

High-performance induction motor facilitates an ideal workpiece clamping force. Clamping power is adapted to the test method and is automatically set to be greater than the test force. Operators do not need to set levels and can rely on the device to guarantee safe, optimized adaption.

SPECIAL CLAMPING DEVICES

QATM is the right stop for advice on complex requirements and clamping devices! It would be our pleasure to advise, devise, customize and implement a solution for you. Only the right component clamping solution can guarantee reliable results.

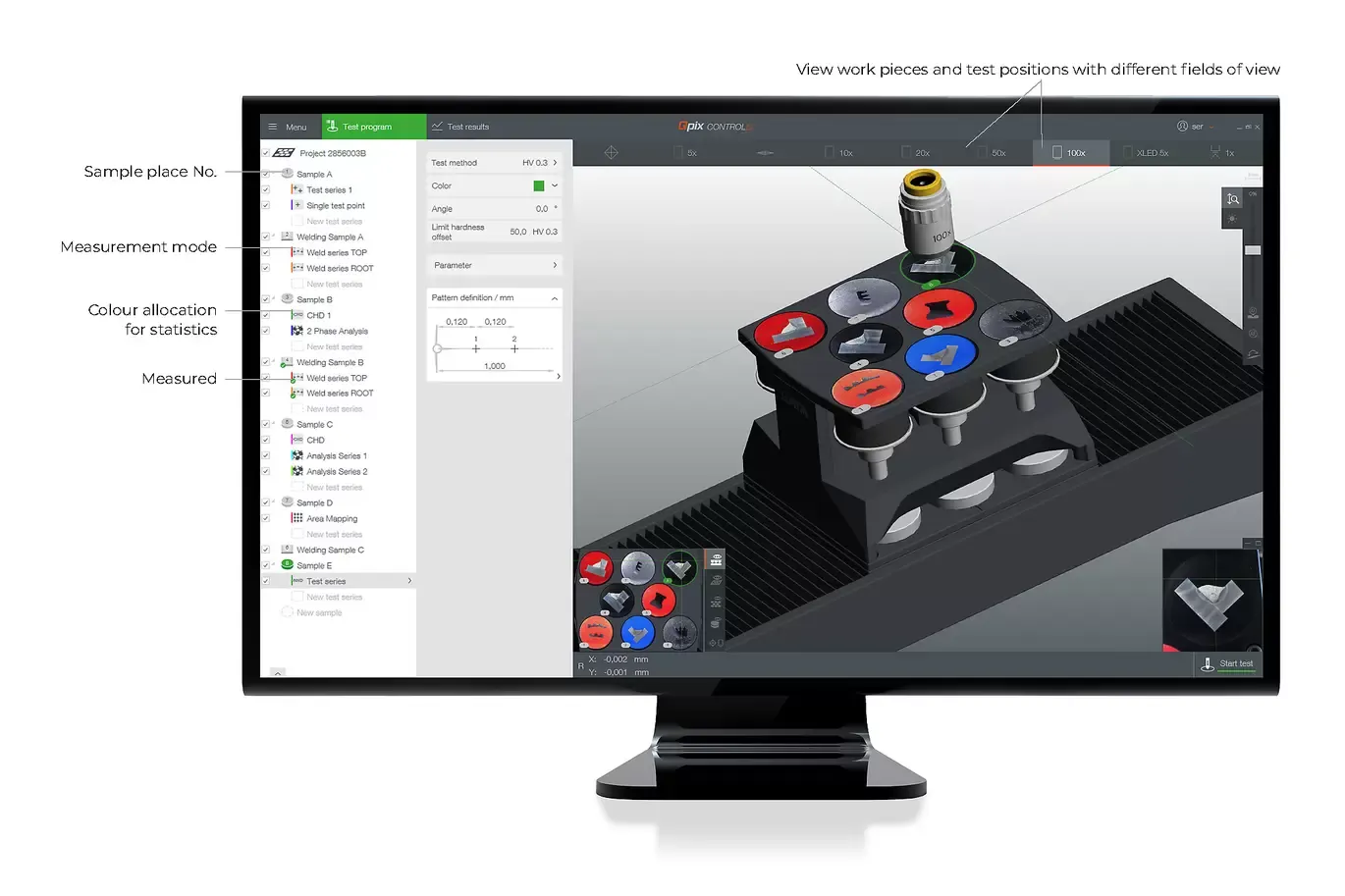

REVOLUTIONARY 3D OPERATING CONCEPT

Intuitive, clearly organized and professional: Qpix Control2 next-generation hardness testing software, developed based on customer feedback and input for maximum user-friendliness. 3D imaging and a whole range of easily understood control elements and views included in the software. It sets new standards in hardness testing.

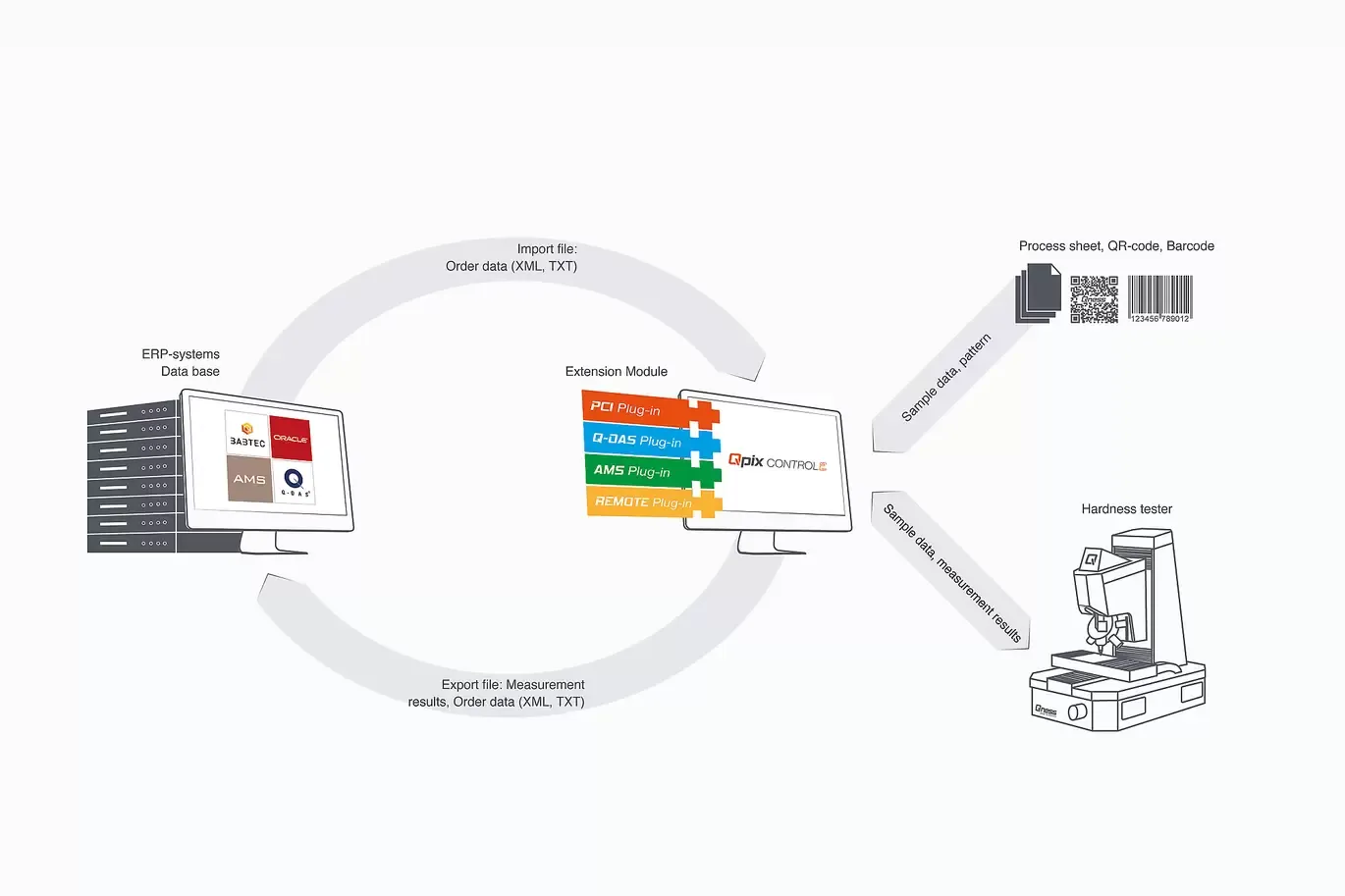

FOR CONNECTED TOMORROWS

Qconnect is the interface in QATM Qpix Control2 software, providing customers with a full portfolio of inter-device connectivity - from serial production, open XML interfaces (bi-directional) and pre-specified plug-in solutions, such as the QDAS Plug-In+, through to customer-specific connectivity solutions implemented completely by QATM. We have a professional solution for every applicational requirement.