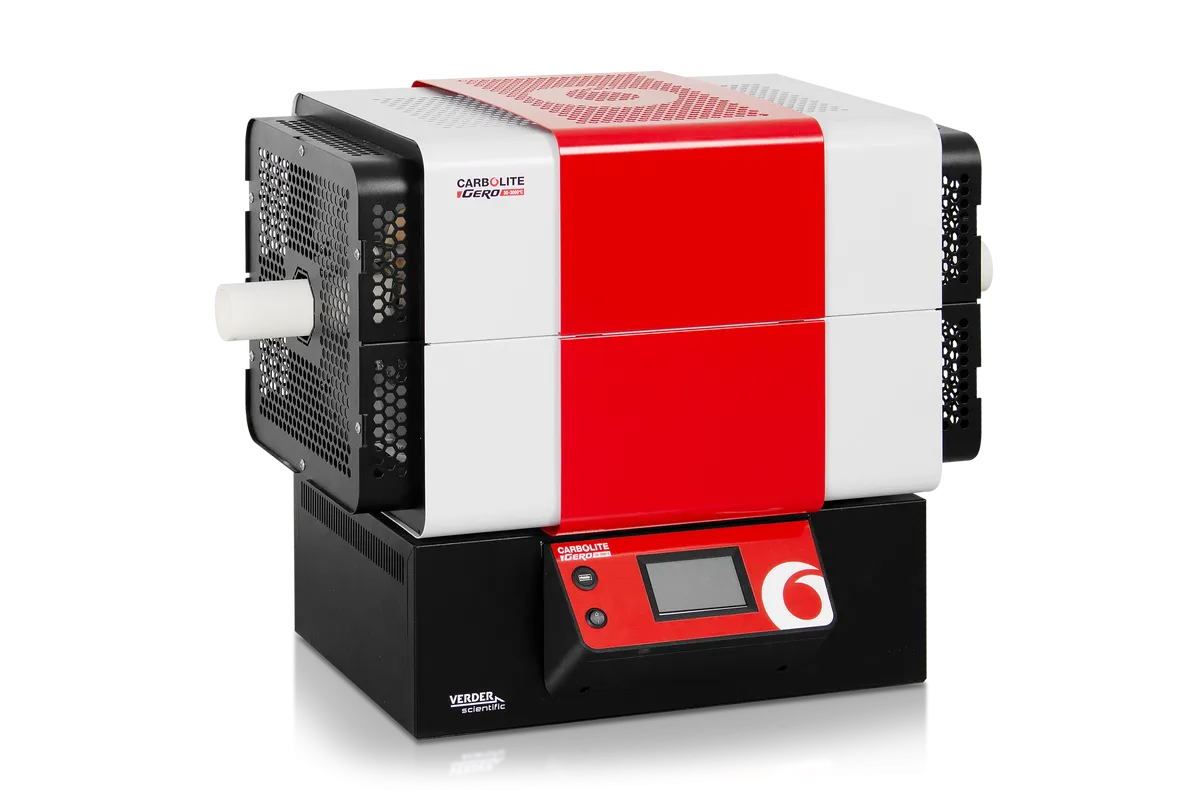

Universal tube furnaces TF

Carbolite Gero’s versatile new TF tube furnace range incorporates high-quality heating elements and innovative thermal insulation design to achieve first class performance while maintaining both reduced case temperatures and power consumption.

LEADING HEAT TECHNOLOGY

- Excellent temperature uniformity

- Fast heat-up and cool-down rates

- Unsurpassed temperature uniformity along the entire heated length

- Low energy consumption

- Low external case temperature

- Designed for longevity

EXCELLENT TEMPERATURE UNIFORMITY: HOT STUFF!

TEMPERATURE CONTROL & COMMUNICATIONS

- Single zone furnaces fitted with Carbolite Gero EPC3016P1 controller

- Three zone furnaces fitted with Carbolite Gero CC-T1 touch-screen controller

OPTIONS

- Over-temperature protection (recommended to protect valuable contents and for unattended operation); 1600°C models are equipped with this option as standard

- A range of sophisticated digital controllers, multi-segment programmers and data loggers is available. These can be fitted with RS232, RS485 or Ethernet communications. - More Information.

RAPID HEATING RATES

Carbolite Gero tube furnaces are equipped with high-quality heating elements designed to achieve fast heat-up rates.

Optimise your lab time by speeding up your heat treatment processes!

Precise temperature measurements are carried out in the Carbolite Gero testing laboratory and available for all models.

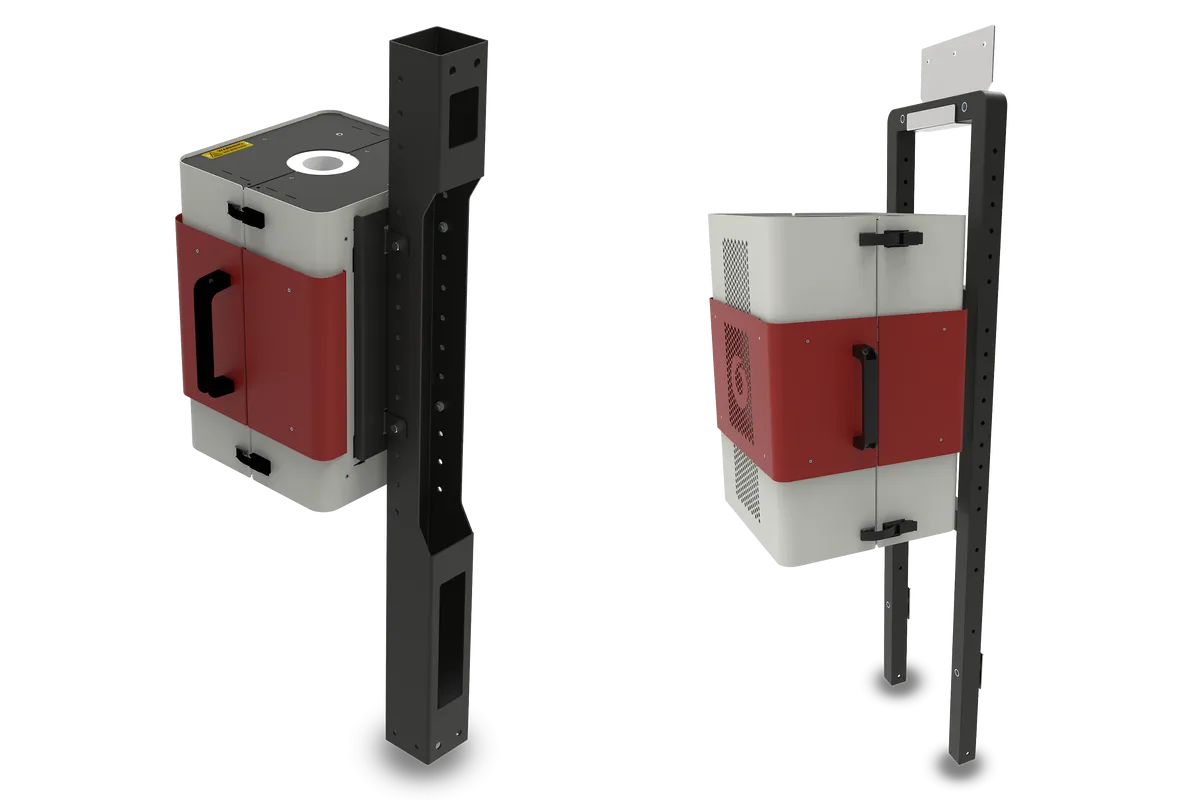

MOUNTING CONFIGURATIONS

- For heated lengths up to 600 mm the furnace body is mounted on top of the control box. The furnace body can easily be detached and separated for remote operation.

- For heated lengths of 800 mm and above the furnace body and control box are always separate.

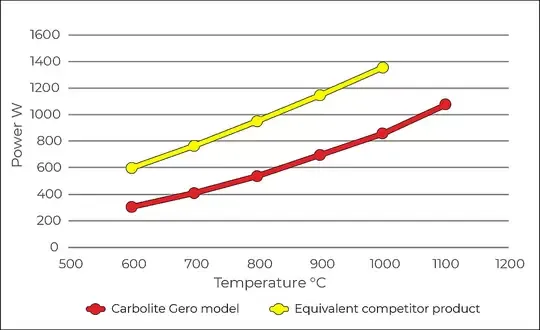

LOW ENERGY CONSUMPTION

MODIFIED ATMOSPHERE & VACUUM EQUIPMENT

- A range of additional work tubes, end seals and complete work tube packages

- Vacuum packages with a choice of rotary vane pumps or turbomolecular pumps

- Inert gas package modules allow for the use of up to 3 non-reactive gases (available with either manual or automatic control)

- Laboratory Gas Safety System for safe use with hydrogen above 750 °C

THAT'S COOL! LOW CASE TEMPERATURE

TECHNICAL DATA

| Number of heated zones | Max temp (°C) | Furnace Ø | Heated length (mm) | Heat-up time (mins) | Tube length for use in air (mm) | Tube length for use with modified atmosphere (mm) | Dimensions:

External H x W x D (mm) | Uniform length ±5°C (mm) | |

| TF1 11/32/150 | 1 | 1100 | 32 | 150 | 27 | 300 | 500 | 455 x 335 x 470 | 58 |

| TF1 12/60/150 | 1 | 1200 | 60 | 150 | 40 | 430 | 600 | 575 x 485 x 480 | 93 |

| TF1 12/60/300 | 1 | 1200 | 60 | 300 | 35 | 580 | 750 | 575 x 495 x 480 | 177 |

| TF1 12/60/450 | 1 | 1200 | 60 | 450 | 45 | 730 | 900 | 575 x 645 x 480 | 318 |

| TF1 12/60/600 | 1 | 1200 | 60 | 600 | 45 | 880 | 1050 | 575 x 795 x 480 | 474 |

| TF1 12/125/400 | 1 | 1200 | 125 | 400 | 88 | 750 | 1000 | 665 x 665 x 480 | 284 |

| TF1 12/125/600 | 1 | 1200 | 125 | 600 | 90 | 950 | 1200 | 665 x 865 x 575 | 456 |

| TF1 12/125/800 | 1 | 1200 | 125 | 800 | 85 | 1150 | 1400 | 445 x 1065 x 575* | 635 |

| TF1 12/125/1000 | 1 | 1200 | 125 | 1000 | 80 | 1350 | 1600 | 445 x 1265 x 575* | 847 |

| TF1 12/125/1200 | 1 | 1200 | 125 | 1200 | 82 | 1550 | 1800 | 445 x 1465 x 575 | 969 |

| TF1 16/60/180 | 1 | 1600 | 60 | 180 | - | 680 | 900 | 665 x 595 x 585 | 100 |

| TF1 16/60/300 | 1 | 1600 | 60 | 300 | - | 800 | 1020 | 665 x 715 x 585 | 175 |

| TF1 16/100/450 | 1 | 1600 | 100 | 450 | - | 1030 | 1250 | 790 x 940 x 705 | 320 |

| TF1 16/100/600 | 1 | 1600 | 100 | 610 | - | 1180 | 1400 | 790 x 1090 x 705 | 425 |

| TF3 12/60/450 | 3 | 1200 | 60 | 450 | 55 | 730 | 900 | 575 x 645 x 480 | 340 |

| TF3 12/60/600 | 3 | 1200 | 60 | 600 | 55 | 880 | 1050 | 575 x 795 x 480 | 501 |

| TF3 12/125/600 | 3 | 1200 | 125 | 600 | 90 | 950 | 1200 | 665 x 865 x 575* | 507 |

| TF3 12/125/800 | 3 | 1200 | 125 | 800 | 85 | 1150 | 1400 | 445 x 1065 x 575* | 715 |

| TF3 12/125/1000 | 3 | 1200 | 125 | 1000 | 80 | 1359 | 1600 | 445 x 1265 x 575* | 855 |

| TF3 12/125/1200 | 3 | 1200 | 125 | 1200 | 82 | 1550 | 1800 | 445 x 1465 x 575* | 1055 |

| TF3 16/100/450 | 3 | 1600 | 100 | 450 | - | 1030 | 1250 | 790 x 940 x 705 | 375 |

| TF3 16/100/600 | 3 | 1600 | 100 | 610 | - | 1180 | 1400 | 790 x 1090 x 705 | 460 |