Universal diffractometer for measuring crystal orientation SDCOM

Артикул: SDCOM

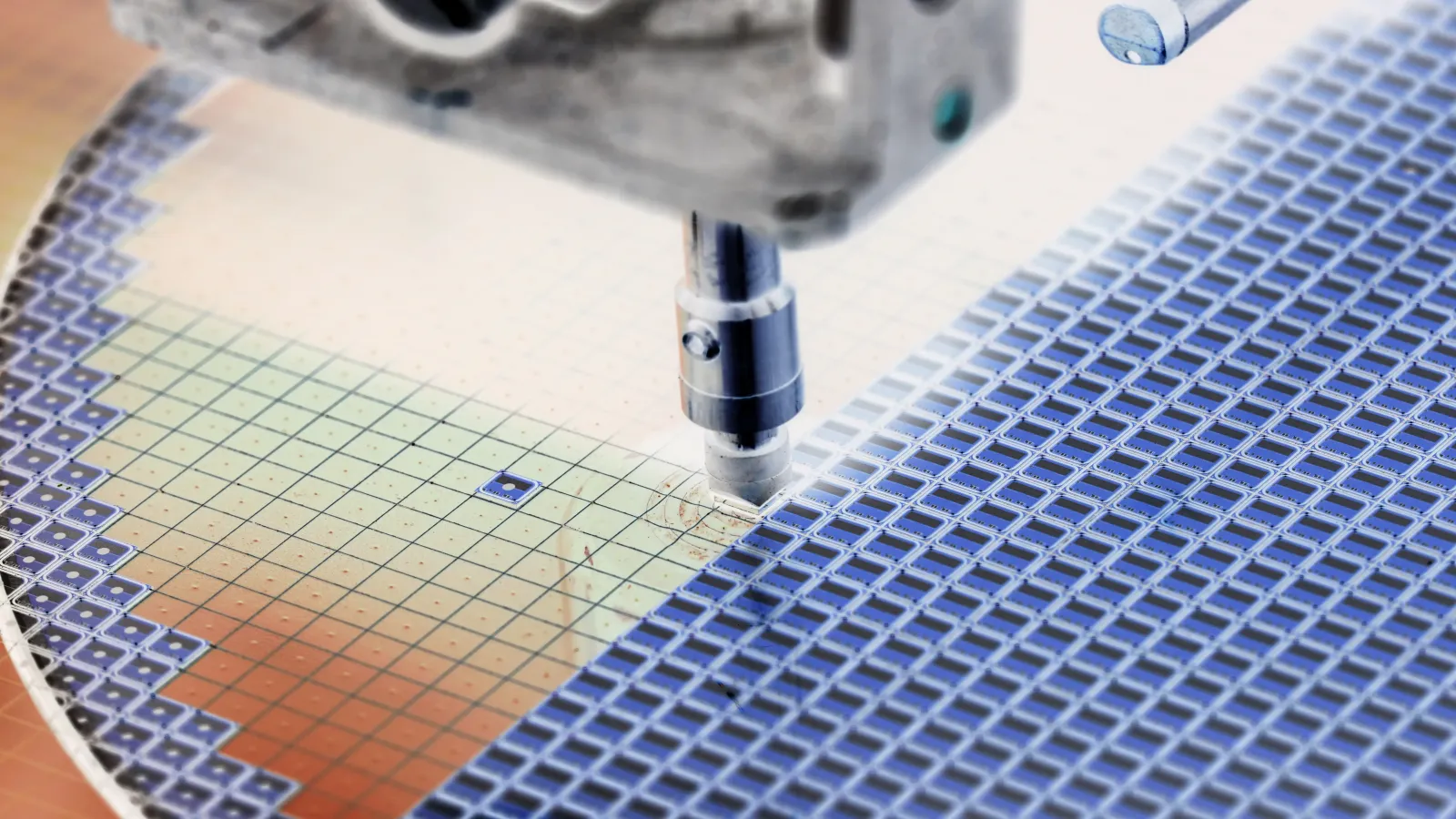

Ultra-fast, top surface measuring crystal orientation in a compact package

Able to measure any single crystal with a diameter between 2 mm to 300 mm, the SDCOM uses the azimuthal scan method to precisely determine the complete lattice orientation of single crystals in just one measuring rotation – taking only a few seconds.

Suitable for both research, production and quality control, the versatile and accessible SDCOM fits easily into a wide range of wafer and ingot process steps while having minimal operational costs due to no requirement for water cooling.

Overview

Quick and precise crystal orientation measurement has never been so accessible – meet the SDCOM, your user-friendly compact XRD. The azimuthal scan method unlocks ultra-fast measurement, with results returned in under ten seconds.

Delivering the highest level of precision of up to 0.01o while supporting a wide variety of accessories, SDCOM is the ideal solution for many applications within wafer processing and research.Features and Benefits

Fast and precise: azimuthal scan method

The azimuthal scan method requires only one measuring rotation to gather all the necessary data to fully determine the orientation, delivering results within 10 seconds whilst not compromising accuracy.

The sample is rotated 360°, with the X-ray source and detector positioned to achieve a certain number of reflections per turn. These reflections enable the orientation of the crystal lattice to be measured in relation to the rotation axis with a high precision of up to 0.01°.

Compact and versatile

Due to its lightweight and compact shape, SDCOM is easily integrable in research or industry processes. The XRD Suite software is both powerful and intuitive, making it convenient and easy to operate for a range of users.

Flexibility is key to the SDCOM, which is especially clear in the range of materials it can measure. The SDCOM can measure crystals starting from 2 mm in diameter up to 300 mm in diameter

For added flexibility, the SDCOM also supports the Theta-scan. With this you can cover an even larger range of materials and off-cuts.

There is also a variety of sample holders and transfer fixtures that can further expand the possibilities of your SDCOM’s applications, ensuring compatibility with your workflow. Manual and motorized wafer mapping stages are also available.

Examples of measurable materials include (azimuthal scan method):

- Cubic, arbitrary unknown orientation: Si, Ge, GaAs, GaP, InP

- Cubic, special orientation: Ag, Au, Ni, Pt, GaSb, InAs, InSb, AlSb, ZnTe, CdTe, SiC3C, PbS, PbTe, SnTe, MgO, LiF, MgAl2O4, SrTiO3, LaTiO3

- Tetragonal: MgF2, TiO2, SrLaAlO4

- Hexagonal and trigonal: SiC 2H, 4H, 6H, 15R, GaN, ZnO, LiNbO3, SiO2 (quartz), Al2O3 (sapphire), GaPO4, La3Ga5SiO14

- Orthorhombic: Mg2SiO4, NdGaO3

- Any other single crystalline material

Cost-effective

SDCOM’s X-ray tube is air-cooled, eliminating the need for a chiller or a cooling water circuit. Thanks to the SDCOM’s efficiency and small footprint, its energy consumption is kept to a minimum – and so are your running costs.

Key Applications

Marking and measuring in-plane directions

SDCOM delivers ultra-fast, highly precise crystal orientation measurements ideal for a range of applications in wafer production and processing, including the marking and measuring of in-plane directions. Lightweight and portable, it can be deployed wherever you need it in your process.

Able to measure small crystals down to 1 mm with high precision and a wide range of materials, SDCOM is well-placed to support the complex and changing needs of the semiconductor industry.

Production quality control

Routine process control demands speed, precision, and repeatability – and SDCOM delivers. Its ultra-fast measurement speed will give your productivity a boost without making a big impact on your running costs, thanks to its desktop format and air-cooled X-ray tube.

Materials research

Able to measure a versatile range of crystal types within a small laboratory footprint, SDCOM is ideal for standard research workflows. Running costs are kept low by minimized energy consumption and an air-cooled X-ray tube with no need for water cooling.

SDCOM is also accessible and easy to operate with manual handling, making it a practical solution for research laboratories with many different users.

Specification

X-ray source | 30 W air-cooled X-ray tube, Cu anode |

| Detectors | Scintillation counter technology |

| Sample holder | Precise turntable, setting accuracy 0.01°, customized sample holders and transfer fixtures |

| Sample diameter | Down to 2 mm ø, up to 200 mm |

| Ambient temperature | ≤ 30° C |

| PC requirements | Windows 10 or latest, . NET Framework update, 2 Ethernet ports |

| Power requirements | 100 to 230 V, single phase, 500 W |

| Dimensions | 600 mm (L) x 600 mm (B) x 840 mm (H) |

Weight | 100 kg |

| Certification | Manufactured under ISO 9001 guidelines, CE conform |