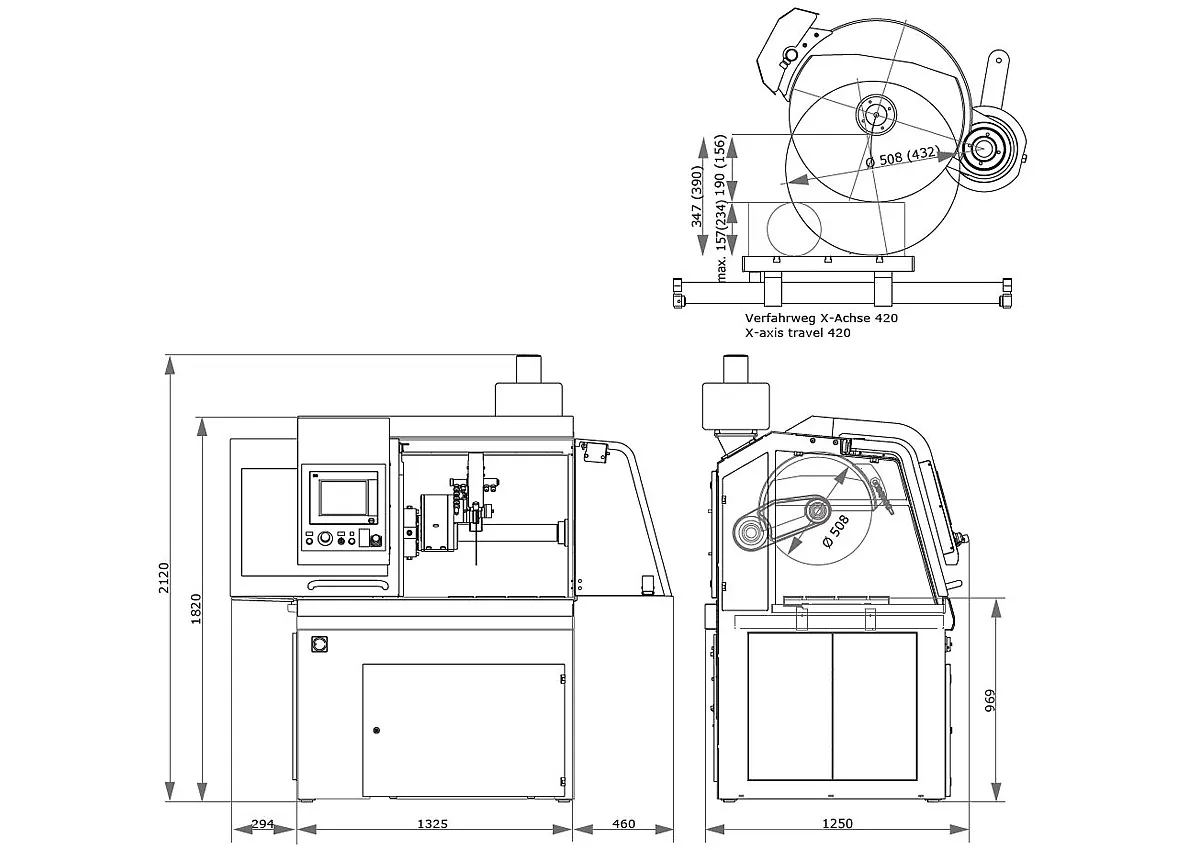

Cut-off machine QCUT 500 A

Артикул: QCUT 500 A

The universal wet cut-off machine Qcut 500 A meets the highest of demands on space available and possibilities for cutting with its innovative concept for design, construction and operation.

The automatic horizontal table (X-axis) and cutting wheel movement (Y-axis) can reach up to 80 mm/sec. through highly dynamic axis drives in rapid-run. Compact program sequences are easy to compile with Touch-Screen display.

The parallel setting of the wheel guard during vertical cutting sequences increases the cutting capacity considerably. The large front and hinged door with safety lock enable access to the machine table with longitudinal and cross T-slots. Recirculating cooling and automatic central lubrication systems are integrated into the robust aluminum construction body of the machine.

PRODUCT ADVANTAGES

- Automatic horizontal movement (X-axis) - please note equipment variation

- Vertical movement (Y-Axis)

- Automatic cross feed of cutting wheel (Z-axis) - please note equipment variation

- High dynamic drive up to 80 mm/sec.

- Multi-position process MPP

- Increased cutting capacity by parallel setting of wheel guard during vertical cutting

- Cutting force control

- Variable pulse-cut feed

- Variable speed

- Incl. cutting wheel arbour with wear ring

- Cutting chamber illumination with LED flex light

- Manual control of all axis by joystick

- Touch-screen display with QATM-software control

- Optical menu navigation for drawing up precise program sequences with position steps and cutting modes

- Storage of unlimited number of programs with password; update and backup via USB

- Remote service/support is available via controller (ISDN connection with router on site required)

- Large sliding and side door for optimal access to cutting chamber; with safety lock during wheel movement

- Sliding door with large window made of scratchproof safety glass

- Options: laser alignment aid, centrifugal separator

- Easy-nut

- Large range of different clamping tools and systems available

- Automatic central lubrication (6 bar compressed air required)

- Solid aluminium case construction, powder coated

- Side openings left and right for continuous parts