High energy ball mill Emax the revolution in ultrafine grinding

The Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the shortest amount of time.

- faster and finer grinding than any other ball mill

- speed of 2000 min-1 allow for ultra-fast pulverization of the sample

- water cooling permits continuous operation without cool down breaks

- temperature-controlled grinding

- narrow particle size distribution thanks to special jar design which improves mixing of the sample

- Max. speed 2000 rpm

- Up to 5 mm feed size and 0.08 µm final fineness

- Two grinding stations for jars of min. 50 ml and max. 125 ml

- GrindControl to measure temperature and pressure inside the jar.

- Aeriation lids to control the atmosphere inside the jar

- Temperature monitoring and temperature-controlled grinding, water-cooling of jars

- Storable SOPs and cycle programs, 4 different jar materials for dry and wet grinding

Application Examples

alloys, bones, carbon fibres, catalysts, cellulose, cement clinker, ceramics, chemical products, clay minerals, coal, coke, concrete, fibres, glass, gypsum, iron ore, kaolin, limestone, metal oxides, minerals, ores, paper, pigments, plant materials, polymers, quartz, semi-precious stones, sewage sludge, slag, soils, tea, tobacco, waste samples, wood, ...

Unique grinding jar geometry

The High Energy Ball Mill Emax combines high-frequency impact, intensive friction, and controlled circular jar movements to a unique and highly effective size reduction mechanism.

Emax - Function & Features

Inserting the grinding jar

Closing the jar clamp

Operating the touchscreen

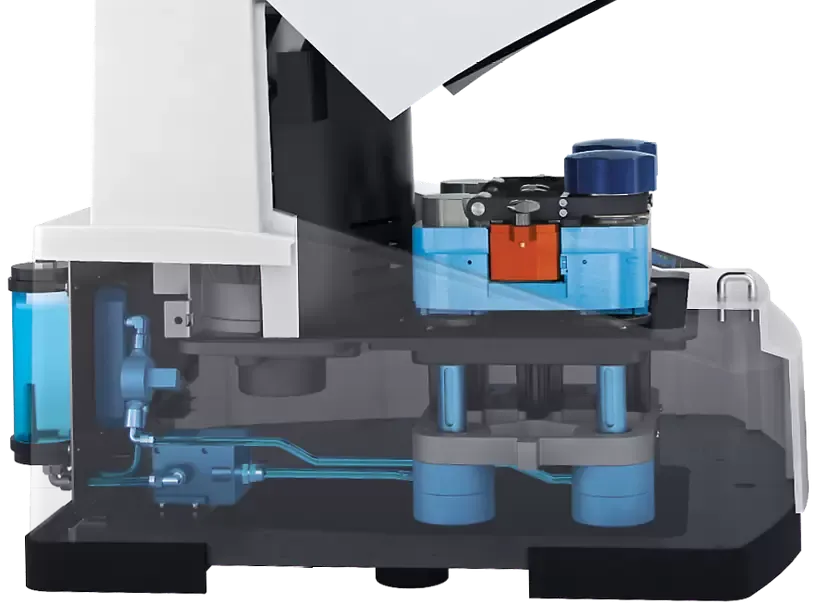

No more cooling breaks

The greatest challenge when developing a high energy ball mill is keeping the temperature under control as the enormous size reduction energy leads to considerable heat built-up inside the grinding jar.

RETSCH solved this problem with an innovative integrated water cooling system. Hence, the Emax usually doesn’t require cooling breaks which are typical for long-term processes in conventional ball mills, even at low speed.

In the Emax the cooling system cools the grinding jars via the jar brackets. This is very effective because heat is more easily discharged into water than into air. The user can choose between 3 cooling modes: in addition to the internal cooling, the mill can be connected to a chiller or the tap to further reduce the temperature.

Function Principle

The High Energy Ball Mill Emax combines high-frequency impact, intensive friction, and controlled circular jar movements to a unique and highly effective size reduction mechanism. The grinding jars have an oval shape and are mounted on two discs respectively which move the jars on a circular course without changing their orientation.

The interplay of jar geometry and movement causes strong friction between the grinding balls, sample material and jar walls as well as a rapid acceleration which lets the balls impact with great force on the sample at the rounded ends of the jars. This significantly improves the mixing of the particles resulting in smaller grind sizes and a narrower particle size distribution than is possible to achieve in ball mills.Accessories for maximum flexibility

Grinding jars in 3 different materials

Available grinding jar sizes are 50 ml, 80 ml and 125 ml, materials include stainless steel, tungsten carbide and zirconium oxide, ensuring contamination-free sample preparation. Grinding balls are available in sizes from 0.1 mm to 25 mm, depending on the material.

Aeration lid

RETSCH offers a special aeration lid for the grinding jars designed for applications where a special atmosphere is to be maintained in the ball mill jar.

GrindControl

The GrindControl measures temperature and pressure inside the jar. The system includes a sensor and transmission unit as well as an analysis software.

Technical Data

| Applications | nano grinding, size reduction, homogenizing, mechanical alloying, colloidal milling, high energy comminution |

| Field of application | agriculture, biology, chemistry, construction materials, engineering / electronics, environment / recycling, geology / metallurgy, glass / ceramics, medicine / pharmaceuticals |

| Feed material | medium-hard, hard, brittle, fibrous - dry or wet |

| Size reduction principle | impact, friction |

| Material feed size* | < 5 mm |

| Final fineness* | < 80 nm |

Batch size / feed quantity* | max. 2 x 45 ml |

| Speed at 50 Hz (60 Hz) | 300 - 2000 min-1 |

| Cooling | controlled integrated water cooling / option: external chiller |

| Temperature control | yes (min and max temperature may be defined) |

| No. of grinding stations | 2 |

| Type of grinding jars | with integrated safety closure devices |

| Material of grinding tools | stainless steel, tungsten carbide, zirconium oxide |

| Grinding jar sizes | 50 ml / 125 ml |

| Setting of grinding time | 00:01:00 - 99:59:59 |

| Interval operation | yes, with optional direction reversal |

| Interval time | 00:01:00 - 99:59:59 |

| Pause time | 00:01:00 - 99:59:59 |

| Storable SOPs | 10 |

| Interface | USB / LAN ( RJ45) |

| Drive | 3-phase asynchronous motor with frequency converter |

| Drive power | 2600 W |

| Electrical supply data | 200-240 V, 50/60 Hz |

| Power connection | 1-phase |

| Protection code | IP 30 |

| Power consumption | ~ 3100W (VA) |

| W x H x D closed | 625 x 525 x 645 mm |

| Net weight | ~ 120 kg |

| Standards | CE |

| Patent / Utility patent | Inclined Grinding bowls (US 8,042,754 B2) |