Knife mill GRINDOMIX GM 200

The knife mill GRINDOMIX GM 200 is the ideal instrument for grinding and homogenizing foods and feeds. With two sharp, robust blades and a powerful 1000 W motor, it allows to process sample volumes up to 0.7 liters quickly and effectively.

THE STANDARD IN THE FOOD INDUSTRY

- Thorough size reduction and homogenization of the entire sample material in seconds

- Pre- and fine grinding in one mill

- Variable speed up to 10,000 min-1 including Boost function with 14,000 min-1 for improved homogenization of tough and sticky samples

- Suitable for sample volumes up to 700 ml

- Cryokit for cold grinding with dry ice available

- 8 SOPs and 4 program cycles can be stored

- Optional gravity lids or volume reduction lids for automatic reduction of the grinding chamber volume

- All parts in contact with the sample material are autoclavable

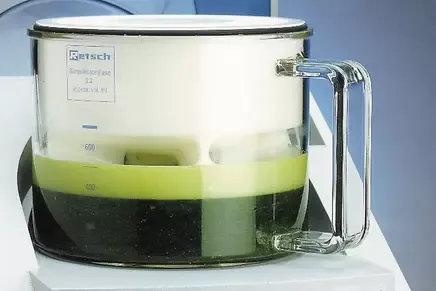

CRYOGENIC GRINDING WITH DRY ICE

To process tough or elastic materials which cannot be homogenized at room temperature, a Cryokit is available to ensure safe and efficient grinding with dry ice. It consists of three components:

EASY AND SAFE OPERATION

The GM 200 is equipped with a 4.3’’ touch display offering easy parameter setting, SOP storage and direct access to the MyRETSCH web portal via QR code. 8 Standard Operating Procedures and 4 program cycles can be stored for routine operations. Before and after the grinding process, the container with its lid, inserted knife and sample, can be installed and removed as a complete unit.

GRAVITY LID ENABLES VARIABLE VOLUME OF THE GRINDING CHAMBER

RETSCH has developed a gravity lid for the GRINDOMIX knife mills which reduces the volume of the grinding container, preventing the sample from escaping the homogenization process by clinging to the container walls. The lid drops under its own weight during grinding and always rests directly on the sample. The result is thorough homogenization of the complete sample material. The gravity lid is also available with overflow channels. It ensures that the cell liquid released by the sample during grinding is returned through these channels to the center of the container, allowing for perfect homogenization.

ACCESSORIES & OPTIONS

A range of different containers, lids and knives makes the GRINDOMIX GM 200 a truly universal device, suitable not only for processing food and feed samples but a wide range of materials.

Patented gravity lid

Automatically adjusts the grinding chamber volume to the changing sample volume.

Gravity lid with overflow channels

Ideally suited to homogenize samples with a high water content.

Stainless steel container

Minimum wear when hard sample materials are processed.

Stainless steel container with baffles

The baffles contribute to a thorough mixing of the sample.

Reduction lid

Reduces the chamber volume to 0.5 or 0.3 liter for optimum homogenization of small sample volumes.

Serrated blade knife

Used for particularly tough samples such as fatty, streaky meat.

Full metal knife

With 4 blades, it is suitable for cold grinding and cutting hard samples.

Cryokit

For homogenizing sticky samples with dry ice

TYPICAL SAMPLE MATERIALS

RETSCH knife mills are suitable for a vast range of applications. Typical materials include candy, cereals, cheese, coated tablets, cocoa nibs, dietary supplements, dried and fresh fruit, feed pellets, fish, frozen products, ham, lettuce, meat, nuts, oil seeds, pharmaceutical products, plant materials, sausages, soap, spices, vegetables etc.

TECHNICAL DATA

| Applications | size reduction, homogenization and mixing |

| Field of application | agriculture, biology, food, medicine / pharmaceuticals |

| Feed material | soft, medium-hard, elastic, containing water / fat / oil, dry, fibrous |

| Size reduction principle | cutting |

| Material feed size* | 40 mm |

| Final fineness* | < 300 µm |

| Batch size / feed quantity* | with standard lid 700 ml

with reduction lid 150-300 ml with gravity lid 300 - 600 ml |

| Grinding chamber volume | with standard lid 1000 ml

with reduction lid 250 ml/500 ml with gravity lid 400 - 800 ml |

| Speed setting | digital, 2,000 - 10,000 min-1 (14,000 min-1 BOOST) |

| Material of grinding tools | blade: stainless steel / titanium

fixation of blade: PVDF / stainless steel container: autoclavable plastic / plastic PP / stainless steel |

| Setting of grinding time | digital, 1 s - 3 min |

| Interval operation | yes |

| Storable SOPs | 8 programms / 4 sequences |

| Drive | series-characteristic motor |

| Drive power | ~ 1000 W |

| Electrical supply data | different voltages |

| Power connection | 1-phase |

| Protection code | grinding chamber and keypad IP 42 |

| Power consumption | ~ 1000 W |

| W x H x D closed | 350 x 275 x 392 mm (opened: 350 x 410 x 553) |

| Net weight | ~ 10 kg |

| Standards | CE |