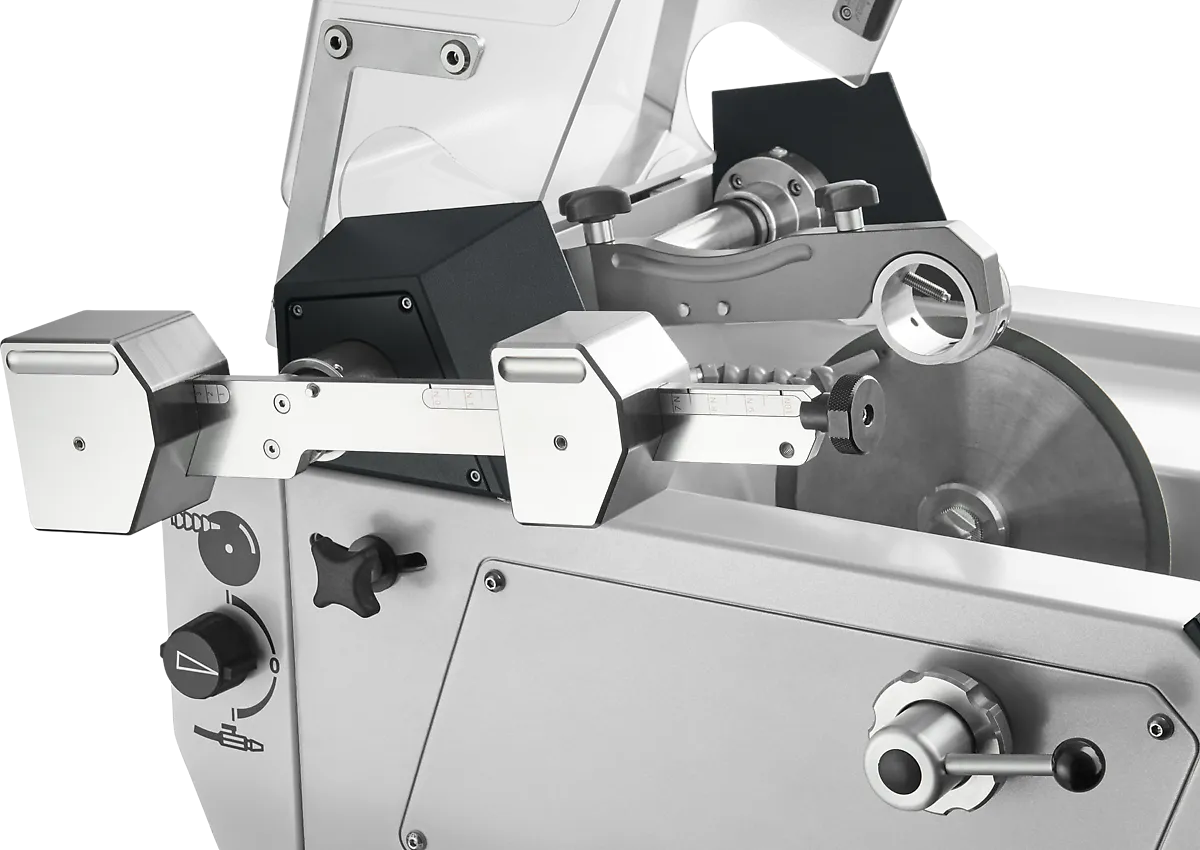

Precision cut-off machine QCUT 150 M

Артикул: QCUT 150 M

The Qcut 150 M is a manual precision cut-off machine with manual cross feed and cutting discs up to a size of 203mm / 8", suitable for a wide range of materialographic and metallographic cutting applications.

Both the cutting force and the speed of the cutting disc are infinitely adjustable. With different operating modes and cooling systems, a very wide range of applications and materials can be covered. The user-friendly fastening system for the clamp arm, specimen holder and table top is designed in such a way that they can be changed toolfree. A wide range of different clamping devices enables versatile use.

PRODUCT ADVANTAGES

- Precision cut-off machine

- Solid stainless steel housing, powder coated

- Manual Y-axis (vertical movement)

- Swivel arm with variable load

- Manual Z-axis with scale

- Variable speed

- Table attachment (accessory)

- 4 different cooling systems availabe

- LED illumination of cutting chamber

- Soft-closing hood

FEATURES

| FUNCTIONAL DESIGN

The powder-coated stainless steel housing is the stable basis of the compact precision cut-off machine. The robust machine design integrates many clearly and ergonomically positioned functions. The cutting chamber, which is equipped with LED lighting, is covered with a transparent protective hood with a soft-close function. |

|

| VARIABLE CUTTING FORCE

The cutting force can be set manually depending on the sample geometry and sample material, which ensures precise and deformation-free cutting of particularly sensitive materials and samples. |

| ADJUSTABLE PARAMETERS FOR VERSATILE APPLICATION

The rotations speed of the precision cutting wheel is infinitely variable adjustable in the range of 150 - 3000 rpm using the rotary knob. Therefore, diamond cutting wheels, diamond cup wheels and corundum cutting wheels can be used for a wide variety of applications. The cutting process is started and ended with the QATM start-stop button. |

|

| MANUAL Z-AXIS

The Qcut 150 M is equipped with a manual Z-axis. For parallel cuts or defined grinding with a diamond cup wheel, the specimen can be fed up to 25 mm across. |

| REDUCES SUBSEQUENT GRINDING PROCESSES

The use of the adaptive rotation axis leads to an even more uniform cutting pattern and reduces the risk of the cut-off wheel running. This reduces the effort required for later plane-parallel grinding of the sample. |

|

EXTENSIVE RANGE OF CLAMPING TOOLS

With the help of a suitable clamping tool from the extensive range of accessories, embedded or non-embedded samples up to a size of Ø 40 mm can be clamped in the cutting machine comfortably.

Larger samples such as PCBs and plate material can be quickly and manually cut with the table top that can be mounted without additional tools.